- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

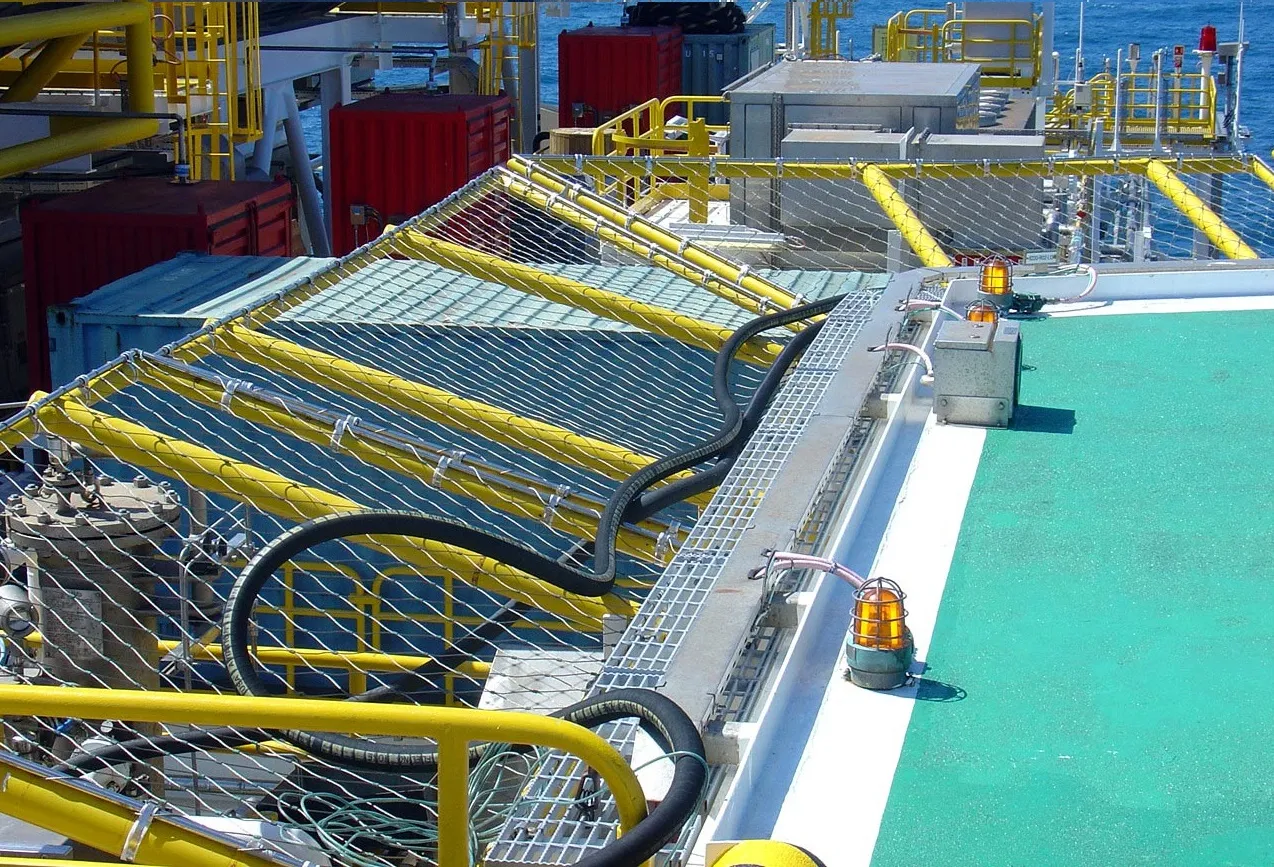

Safety Netting Solutions for Chain Link Helipad Perimeters to Enhance Security and Protection

Ensuring Safety with Chain Link Helipad Perimeter Safety Netting

In the modern world of aviation, safety remains an uncompromising priority, particularly in the realm of helipads. Helicopter operations involve unique challenges, given the intricate nature of their takeoff and landing. One significant aspect of maintaining safety around helipads is the use of chain link helipad perimeter safety netting. This specialized netting system plays a crucial role in safeguarding both personnel and equipment from potential accidents, enhancing operational efficiency, and ensuring compliance with safety regulations.

Understanding Helipad Safety Needs

Helipads are often situated in urban environments where the risk of accidents or unauthorized access can have severe consequences. The high-speed landings and takeoffs of helicopters necessitate a buffer zone – an area designed to protect ground staff, equipment, and facilities from the downdraft generated by rotors. Therefore, adequate perimeter safety measures are paramount.

Chain link safety netting serves as a robust barrier around helipads, acting as a protective perimeter that keeps unauthorized personnel at a safe distance. This type of netting is distinguished by its resilience and flexibility, making it ideal for high-intensity aviation environments. Made from durable materials, chain link netting is designed to withstand various environmental conditions, including wind, rain, and temperature fluctuations.

Benefits of Chain Link Safety Netting

1. Enhanced Safety The primary function of the chain link netting is to prevent accidents and injuries by controlling access to the helipad area. The netting effectively acts as a visual deterrent, signaling to personnel and visitors that they should maintain a safe distance.

chain link helipad perimeter safety netting

2. Visibility and Accessibility Unlike solid barriers that can obstruct visibility, chain link netting allows for unobstructed views of helicopter operations. This visibility is essential for ground staff, as it facilitates better communication and coordination during takeoff and landing.

3. Cost-Effectiveness Chain link netting is often more affordable and easier to install than other forms of perimeter fencing. Its lightweight construction and modular design allow for quick installation and scaling as operational needs evolve.

4. Maintenance and Durability The materials used for chain link netting are designed to withstand the rigors of outdoor environments. They require minimal maintenance, which is a significant advantage for busy helipad operations. Regular inspections are simple, ensuring that the netting remains in good condition.

Regulatory Compliance

Adherence to aviation safety regulations is non-negotiable in the operation of helipads. Many regulatory bodies stipulate the need for safety barriers around helicopter landing zones. Utilizing chain link helipad perimeter safety netting can help operators comply with these standards while also fostering a culture of safety within their organizations.

Conclusion

As helicopter traffic increases in urban areas and remote locations, ensuring safe landing and takeoff operations has never been more critical. Chain link helipad perimeter safety netting stands out as a reliable solution, combining visibility, accessibility, and cost-effectiveness. By adopting this safety measure, operators can create a secure environment that protects personnel and equipment, ultimately leading to more efficient helicopter operations. As advancements in aviation technology continue to evolve, prioritizing safety with effective barriers such as chain link netting will remain essential for the future of helicopter aviation.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025