- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

chain link helideck mesh

The Importance of Chain Link Helideck Mesh for Safety and Efficiency

In the modern era of aviation and offshore operations, ensuring the safety and efficiency of helidecks is paramount. One of the crucial components contributing to this objective is the chain link helideck mesh. This specialized mesh serves multiple purposes, from enhancing the structural integrity of helidecks to providing safety measures for helicopter operations.

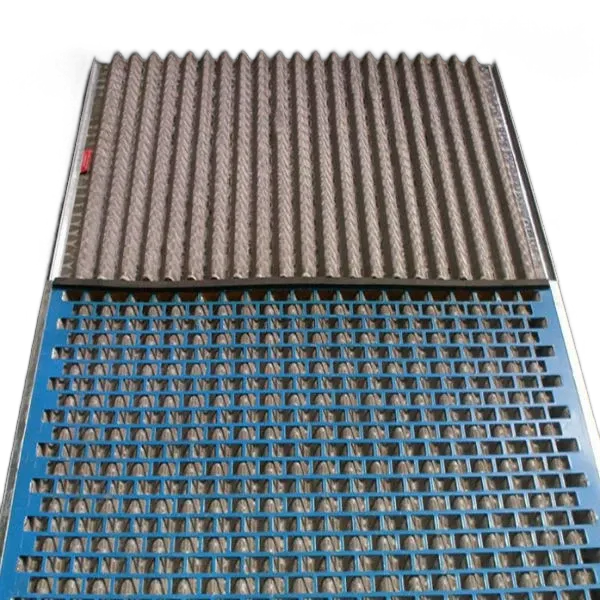

Helidecks are commonly found on offshore platforms, vessels, and high-rise buildings, serving as landing and takeoff zones for helicopters. Due to the dynamic environment in which helicopters operate, the design and materials used in helideck construction are critical. Chain link helideck mesh, made from durable materials like galvanized steel or other corrosion-resistant substances, offers a robust solution for ensuring safety during helicopter landings.

One of the primary benefits of chain link helideck mesh is its ability to provide a strong barrier between the helicopter and the underlying structure. This mesh acts as a safety net, minimizing the risk of accidents during landing and takeoff. It prevents loose materials from falling through the deck, which could potentially strike personnel or equipment below. Additionally, the mesh design allows for visibility and airflow, ensuring that helicopter pilots can maintain clear sightlines during landing.

Beyond safety, the chain link helideck mesh also plays a role in enhancing the operational efficiency of helicopter services

. The open structure of the mesh allows for easy drainage of water, preventing the accumulation of rainwater and reducing the risk of hydroplaning during landings. This drainage capability is particularly critical in preventing slips and ensuring stable ground conditions.chain link helideck mesh

The maintenance of helidecks is another aspect where chain link helideck mesh proves advantageous. The materials used for the mesh are generally low-maintenance and can withstand harsh environmental conditions, including saltwater exposure and high winds. Regular inspections and minimal upkeep are typically sufficient, ensuring that the helideck remains in optimal working conditions for extended periods.

Moreover, the installation of chain link helideck mesh is relatively straightforward. Its versatility allows it to be custom-fitted to various helideck shapes and sizes, ensuring that it can meet specific operational requirements. This adaptability is crucial for industries such as oil and gas, where platforms may have unique designs based on location and function.

In terms of safety regulations, many aviation authorities and offshore regulatory bodies emphasize the importance of installing such safety features on helidecks. Compliance with these regulations not only ensures safe operations but also enhances the credibility and reliability of the operator in the eyes of regulatory bodies and clients alike. By investing in quality chain link helideck mesh, operators demonstrate their commitment to safety and efficiency, which can lead to improved operational performance and reduced liability.

In conclusion, chain link helideck mesh is an invaluable component of modern helideck design and operation. It enhances safety by preventing accidents and minimizing risks, promotes operational efficiency through effective drainage, and ensures ease of maintenance. With the continued growth of offshore operations and the increasing reliance on helicopter services, investing in high-quality chain link helideck mesh is essential for future-ready aviation and offshore companies.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025