- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

buy steel grating

Everything You Need to Know About Buying Steel Grating

Steel grating is a versatile material used in various applications, from industrial flooring to architectural designs. Its strength, durability, and ability to provide excellent drainage make it a popular choice for many projects. If you're considering purchasing steel grating, it's essential to understand the factors that influence your decision, the types available, and key considerations to ensure you make the best choice for your needs.

Understanding Steel Grating

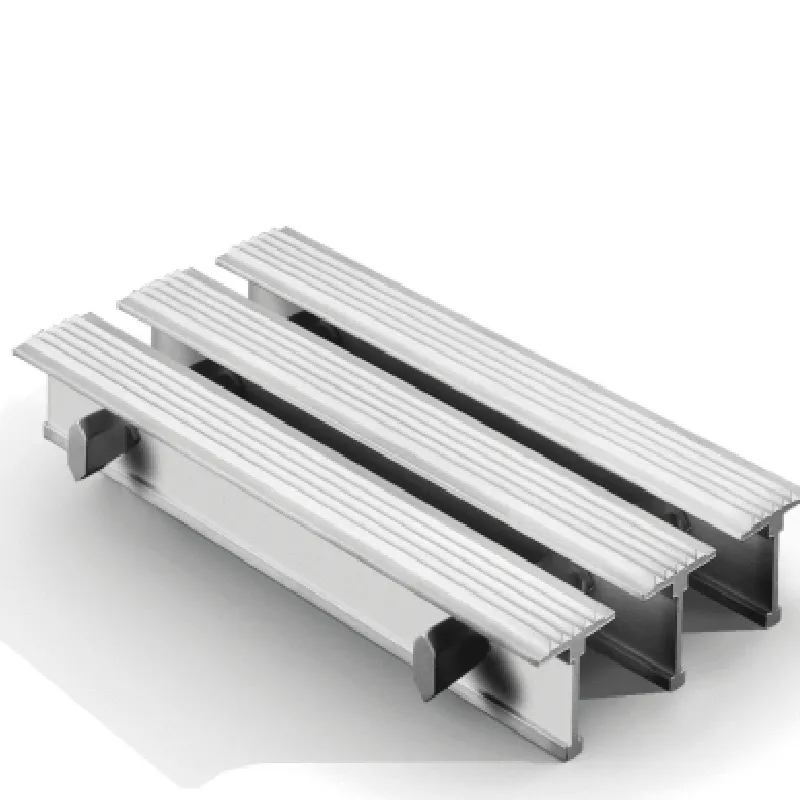

Steel grating is a flat metal structure made from steel bars that are arranged in a grid pattern. This design allows for both strength and ventilation, making it suitable for a wide range of uses, including walkways, platforms, ramps, and stair treads. Steel grating is typically designed to support heavy loads while allowing light and air to pass through, which is crucial for areas where drainage is necessary.

Types of Steel Grating

1. Bar Grating This is perhaps the most common form of steel grating. It's composed of parallel bars held together by appropriate spacing. Bar grating can be made from various steel types, including carbon, stainless, or galvanized steel, depending on the application and the environment it will be exposed to.

2. Heavy-Duty Grating Designed for high-load applications, heavy-duty grating is thicker and can support more weight compared to standard bar grating. This type is pivotal in industrial settings, such as chemical plants or manufacturing facilities.

3. Mesh Grating Mesh grating provides a different structural aesthetic while ensuring safety and functionality. It consists of a grid-like structure that can serve various purposes, including railings or fencing.

4. Fiberglass Grating Although primarily not steel, fiberglass grating is worth mentioning for its advantages in specific environments, particularly where corrosion is a concern. It's lightweight, resistant to chemicals, and can be an excellent alternative to steel grating in certain applications.

Key Considerations When Buying Steel Grating

buy steel grating

1. Material Specifications Understanding the type of steel is crucial. Galvanized steel offers excellent corrosion resistance, making it ideal for outdoor applications, while stainless steel may be necessary for environments exposed to harsh chemicals.

2. Load Capacity Consider the expected load on the grating. Manufacturers provide load tables that can help determine the appropriate grating type based on anticipated loads. It's vital to err on the side of caution and select grating that exceeds the maximum expected loads.

3. Spacing and Bar Size The spacing between the bars, as well as their size, directly influences the strength and safety of the grating. Bar size also impacts the weight of the grating, which can be a vital consideration in construction or installation.

4. Surface Finish The surface finish can affect safety, especially in areas exposed to moisture or spills. Anti-slip finishes, such as serrated or galvanized surfaces, are valuable in maintaining traction and preventing slips and falls.

5. Compliance and Standards Ensure that your chosen steel grating meets relevant industry standards and safety regulations. This compliance is often required for commercial projects and ensures that the material is up to code.

6. Cost and Availability Prices for steel grating can vary significantly depending on the material, size, and type. It's essential to compare prices and availability from multiple suppliers. Bulk purchases may offer discounts, so consider that if you have large quantities to buy.

7. Supplier Reputation When looking to buy steel grating, consider the reputation of the supplier. Reading reviews and asking for recommendations can help find a dependable source. A reputable supplier will not only provide high-quality materials but also offer valuable advice regarding your specific project needs.

Conclusion

Buying steel grating can seem daunting given the various options and factors to consider. However, by understanding the types of grating available, evaluating material specifications, and considering safety and compliance factors, you can make an informed decision that meets your needs. Whether you're refurbishing an old structure or building something new, investing in quality steel grating will ensure a durable and reliable solution for years to come. Always remember to consult with industry professionals or suppliers for tailored advice, ensuring that your project is successfully completed.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025