- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

bar grating weights

Understanding Bar Grating Weights A Comprehensive Overview

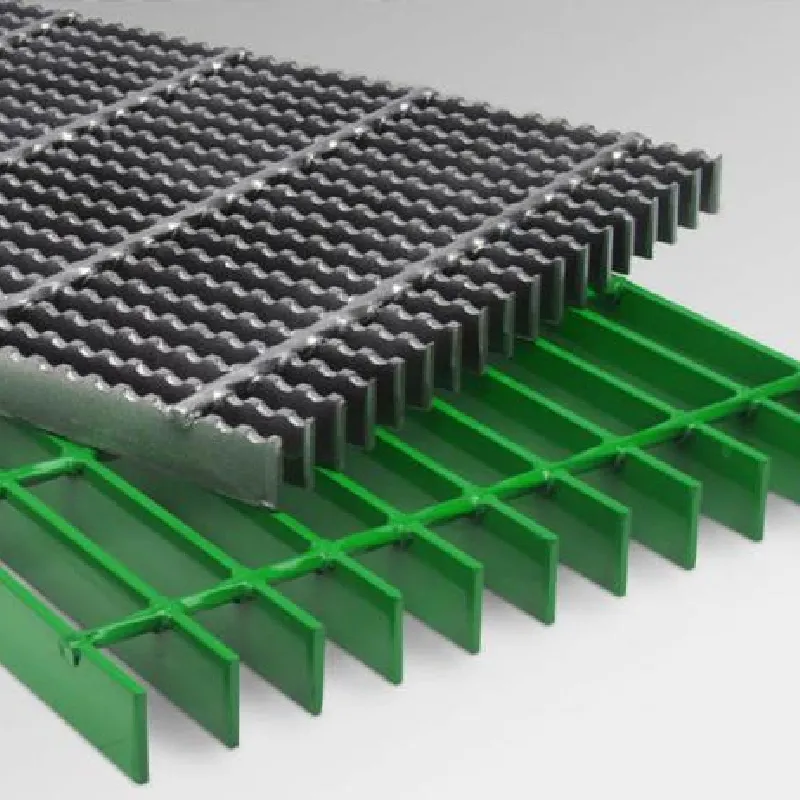

Bar grating is an essential component in various industries, serving diverse purposes such as flooring, walkways, and platforms. One crucial factor to consider when selecting the right bar grating for a specific application is its weight. The weight of bar grating not only influences its load-bearing capacity but also impacts installation, maintenance, and overall project costs. In this article, we will delve into the intricacies of bar grating weights, discussing its types, factors affecting weight, and implications for usage.

Types of Bar Gratings

Bar grating comes in several types, including welded, pressed, and swaged. Each type has distinct characteristics that influence its weight

1. Welded Bar Grating This type consists of bearing bars and cross bars welded together at their intersections. The weight of welded grating depends on the dimensions of the bars used. Typically, heavier duty options can sustain larger loads.

2. Pressed Bar Grating Made by permanently pressing the bearing bars into the cross bars, this type has a lighter weight compared to welded gratings. The pressed design often results in a higher percentage of open area, which may be beneficial for drainage.

3. Swaged Bar Grating This type is manufactured by swaging the cross bars into the bearing bars, providing a strong and lightweight option. The swaging process allows for thinner bars, reducing overall weight while maintaining structural integrity.

Factors Affecting Bar Grating Weight

Several factors contribute to the overall weight of bar grating

- Material The choice of material significantly affects weight. Common materials include carbon steel, stainless steel, and aluminum. Generally, aluminum grating is much lighter than steel alternatives, making it ideal for applications where weight is a consideration.

- Bar Size and Spacing The height and thickness of the bearing bars, as well as the spacing between them, play a vital role in determining weight. Greater heights and thicknesses increase weight but may also improve load-bearing capacity.

bar grating weights

- Bar Pattern The pattern of the grating (e.g., square or rectangular) can influence both aesthetics and weight distribution. Some patterns may offer a balance between weight and strength.

- Return Sides and Flanges Some bar grating designs include return sides or flanges for added strength and stability. These features can increase weight, so it's important to consider the trade-offs.

Implications for Usage

Understanding bar grating weights is crucial for several reasons

- Load-Bearing Capacity The weight directly correlates with how much load the grating can handle. Heavy-duty gratings are essential in industrial settings where substantial loads are expected, whereas lighter ones are suited for pedestrian applications.

- Installation Lighter gratings are easier to handle and install, which can reduce labor costs and time. This is particularly relevant in projects with limited accessibility or for higher floors.

- Transportation The weight of bar grating also affects transportation costs. Heavier materials require more robust shipping equipment and may incur greater shipping fees, influencing overall project budgets.

- Maintenance The weight can affect maintenance routines as well. Lighter grating may be easier to clean and maintain, making it advantageous in environments susceptible to debris accumulation.

Conclusion

Bar grating weights are a pivotal aspect of selecting the right grating for any project. Understanding the types of grating, the factors influencing their weight, and the implications for usage can help in making informed decisions. By considering these elements, industries can ensure they choose appropriate bar grating that meets their load requirements while balancing cost and installation efficiency. Whether for industrial use or architectural applications, the right bar grating contributes significantly to the safety and functionality of any environment.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025