- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

bar grating steps

Understanding Bar Grating Steps A Comprehensive Overview

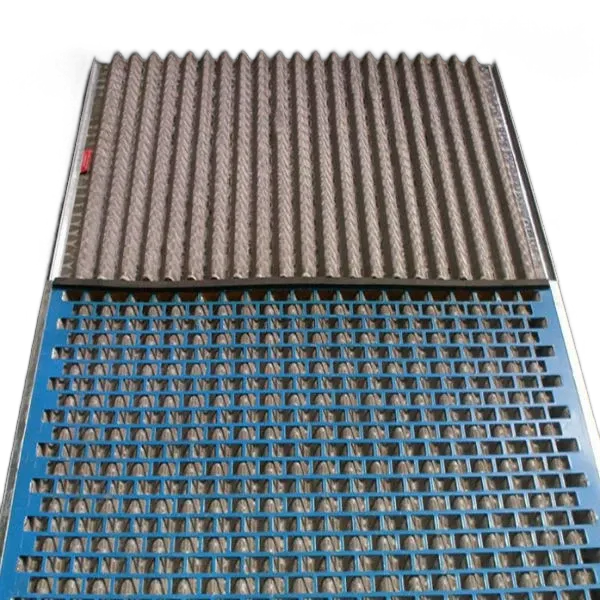

Bar grating is a popular construction product used in various industries, including construction, manufacturing, and infrastructure. These gratings are made up of a series of parallel bars that are spaced apart to allow for air flow, water drainage, and light penetration. One of the critical aspects of implementing bar grating is understanding the steps involved in its installation and maintenance. This article will delve deeper into the essential steps and considerations associated with bar grating.

Step 1 Planning and Design

Before any grating can be installed, careful planning and design are essential. This involves assessing the specific needs of the project, including load requirements, spacing, and environmental conditions. Factors such as the type of materials involved, the width of the bars, and the overall dimensions of the grating must be considered. It is crucial to consult relevant codes and standards to ensure compliance and safety in the design phase. Collaborating with engineers and architects will also provide valuable insights to create a durable and effective grating system.

Step 2 Selecting the Right Material

Bar gratings can be made from a variety of materials, including steel, aluminum, and fiberglass. Each material has its unique properties and suitability for specific applications. For example, steel is known for its strength and durability, making it suitable for heavy-load applications. Aluminum, while lighter, offers excellent corrosion resistance, making it ideal for outdoor settings. Fiberglass gratings are another option, especially in environments where chemical exposure occurs. Selecting the right material ensures the longevity and effectiveness of the grating system in its intended application.

Step 3 Preparing the Site

Preparation of the installation site is a vital step that cannot be overlooked. The area where the bar grating will be installed should be cleared of any debris, uneven surfaces, or obstacles that could hinder installation. If the grating is to be mounted on a structural element, such as a concrete slab or a steel frame, ensure that these surfaces are also clean and in good condition. Proper site preparation not only helps facilitate a smoother installation process but also contributes to the safety and effectiveness of the final installation.

bar grating steps

Step 4 Installation

The installation of bar grating requires meticulous attention to detail. Various methods exist for securing the gratings, including bolting, welding, or using clips. The chosen method usually depends on the type of grating and the requirements of the project. It is essential to follow the manufacturer's recommendations for installation to minimize risks of displacement or failure under load. During installation, ensure that the grating is adequately aligned and leveled to prevent any structural issues.

Step 5 Safety Measures

Safety should always be a priority when working with bar grating. The installation process may involve working at heights or with heavy materials, which can pose various risks. Proper personal protective equipment (PPE), such as helmets, gloves, and safety goggles, should be worn at all times. Additionally, it is vital to conduct regular inspections of the installed grating system to identify and rectify any issues before they escalate, such as corrosion or damage.

Step 6 Maintenance

Finally, regular maintenance of bar grating is essential to ensure its longevity and performance. This includes periodic inspections for damage, debris accumulation, or signs of wear. Cleaning the grating surface to remove accumulated dirt or materials is also vital, especially in environments where slips and falls are a concern. Depending on the material used, specific care and preventive treatments might be necessary to protect against rust, corrosion, or other forms of degradation.

Conclusion

Bar grating serves a multitude of functions in various applications, making it an essential component in many industries. By following the outlined steps—from planning and selecting materials to installation and maintenance—users can ensure that their bar grating systems are safe, effective, and durable. Whether for heavy industrial use or aesthetic architectural elements, understanding these steps is crucial for achieving the best results with bar grating.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025