- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Understanding the Basics of Bar Grating Steps and Their Applications in Architecture

Understanding Bar Grating Steps A Comprehensive Guide

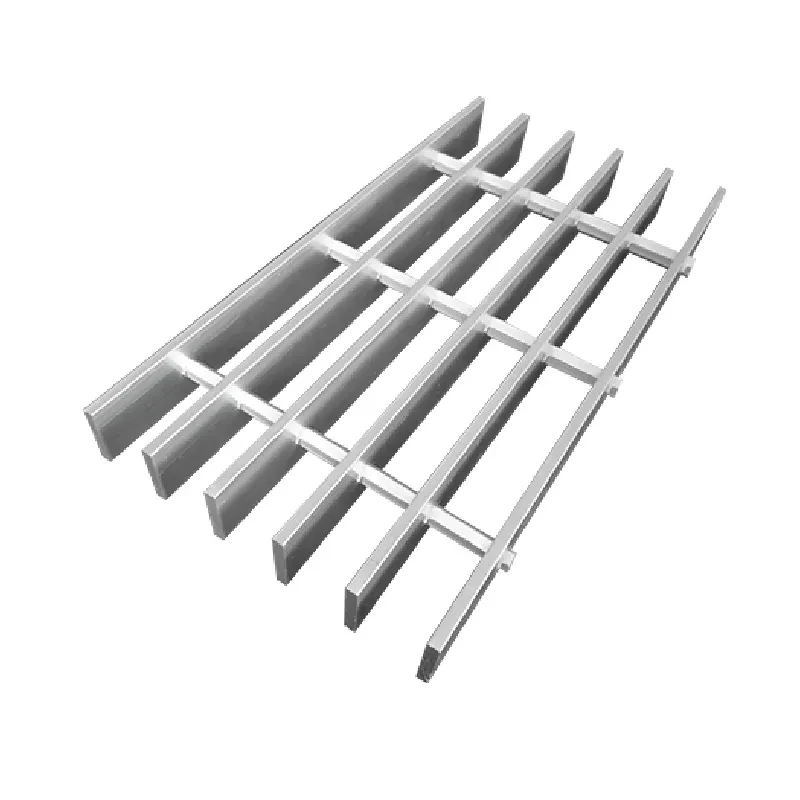

Bar grating is a popular type of flooring material, widely used in industrial and commercial environments. Its design consists of a series of parallel bars, typically made from steel, aluminum, or fiberglass, which are spaced apart to allow for drainage and air circulation while providing a sturdy walking surface. Bar grating offers several advantages, including lightweight construction, high load-bearing capabilities, and ease of installation. In this article, we will explore the steps involved in the selection, installation, and maintenance of bar grating.

Step 1 Selection of Bar Grating

The first step in utilizing bar grating is selecting the appropriate type for your specific needs. Various factors influence this decision

1. Material The choice between steel, aluminum, and fiberglass will depend on the corrosive environment, load requirements, and budget constraints. Steel is durable and cost-effective, while aluminum is lightweight and resistant to corrosion. Fiberglass is ideal for corrosive environments but may be more expensive.

2. Load Capacity Understanding the load capacity required is crucial for safety. Bar grating is classified according to its load-bearing capabilities. Utilize load tables provided by manufacturers to determine the correct type based on anticipated foot traffic and the weight of equipment that may be used on the grating.

3. Spacing and Bar Size The spacing between bars and the thickness of each bar also affects strength, weight, and safety. Closer spacing enhances safety by reducing the risk of objects falling through, while thicker bars offer greater strength.

Step 2 Installation Process

Once the appropriate type of bar grating is selected, the next step is installation

1. Preparation of the Site Ensure the installation area is clean and level. Remove any debris, old flooring, or obstacles that could hinder installation.

bar grating steps

2. Cutting the Grating Bar grating usually comes in standard sizes but may need to be cut to fit your specific area. Use a saw with a proper blade suitable for the material to make precise cuts.

3. Aligning and Fastening Position the grating panels on the desired location, ensuring they fit snugly. Secure the grating using appropriate fasteners, such as bolts or clips, ensuring that they are evenly distributed for stability.

4. Safety Measures During installation, employ safety measures including wearing protective gear, ensuring proper lifting techniques, and working in pairs when handling large panels.

Step 3 Maintenance of Bar Grating

Bar grating requires minimal maintenance, but regular checks will prolong its life and maintain safety

1. Cleaning Periodically clean the grating to remove dirt, chemicals, or debris that may accumulate. Use a power washer or scrub brush for tough stains, ensuring that the cleaning method is compatible with the grating material.

2. Inspection Regularly inspect the grating for any signs of wear, corrosion, or structural weakness. Pay close attention to the fasteners, making sure they remain tight and intact.

3. Repairs If damage is found, make the necessary repairs or replacements quickly. Small issues can lead to larger, more expensive problems if not addressed promptly.

In conclusion, understanding the steps involved in selecting, installing, and maintaining bar grating is essential for safety and longevity. By carefully considering material choices, adhering to proper installation techniques, and committing to regular maintenance, bar grating can provide a safe and durable solution for various flooring needs. Whether used in walkways, platforms, or industrial settings, bar grating is an excellent choice that balances functionality and resilience.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025