- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

bar grating sizes

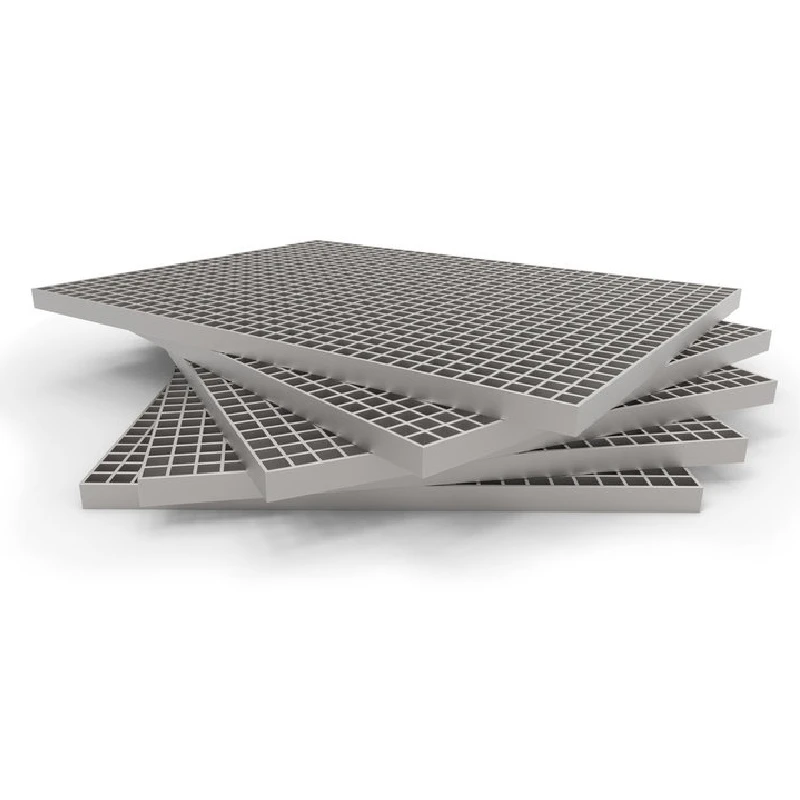

Understanding Bar Grating Sizes A Comprehensive Guide

Bar grating is an essential component in various industrial and architectural applications. This versatile product, made from a series of parallel bars that are spaced at regular intervals, is widely used for walkways, platforms, drainage covers, and even aesthetic projects. The effectiveness of bar grating largely depends on its size, configuration, and material. Hence, understanding the different sizes of bar grating is crucial for engineers, architects, and project managers.

What is Bar Grating?

Bar grating is typically manufactured from metals such as steel, aluminum, or stainless steel, which provides a strong and durable solution for load-bearing applications. The primary purpose of bar grating is to provide a safe walking surface while allowing for drainage and ventilation. Available in a variety of styles, including welded, swaged, and press-locked, bar grating can be customized to suit specific requirements by altering the dimensions and spacing of the bars.

Common Sizes of Bar Grating

The size of bar grating is usually described in terms of its width, height, and spacing. The most common bar sizes are

1. Bar Thickness The thickness of the bars generally ranges from 1/4 inch to 1 inch. Thicker bars offer higher load capacities but may also be heavier, affecting ease of installation and transport.

2. Bar Spacing Bar spacing, which refers to the distance between the bars, can range from 1 inch to 4 inches. Closer spacing creates a more stable surface while allowing less debris to fall through. For example, a spacing of 1 inch is often used in facilities where safety is paramount, such as in food processing or pharmaceutical environments.

3. Width of the Grating Panels Standard widths for grating panels are typically 24 inches or 36 inches, but custom widths can be fabricated to meet specific project needs.

bar grating sizes

4. Length of the Grating Panels Bar grating panels can be manufactured to various lengths, generally from 2 feet to 20 feet. Custom lengths are also available, enabling designers to minimize waste and optimize performance.

Load Capacity Considerations

When selecting the size of bar grating, load capacity is a significant consideration. Manufacturers often provide load tables that specify the maximum load the grating can support based on its dimensions and material. It’s important to note that heavier loading often requires a thicker bar or closer bar spacing. Additionally, local building codes may impose specific standards that need to be adhered to when determining the appropriate grating size.

Applications of Bar Grating

1. Industrial Use In industrial settings, bar grating serves as flooring for walkways, maintenance access, and machine platforms due to its robust characteristics.

2. Public Infrastructure Bar grating is commonly used in public spaces such as parks and pedestrian walkways, where it provides safe footing while allowing water drainage.

3. Architectural Aesthetics Designers are increasingly using decorative bar grating in commercial and residential building projects to enhance aesthetics and functionality.

Conclusion

Choosing the right bar grating size is crucial for ensuring safety, durability, and effective performance in various applications. By understanding the types of bar thickness, spacing, and the specific load capacities, professionals can make informed decisions that meet their project requirements. Whether for industrial use or creative architectural projects, bar grating remains a reliable solution that combines strength with versatility. As technology and material science advance, the options for bar grating will only expand, enabling even more innovative applications in the future.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025