- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

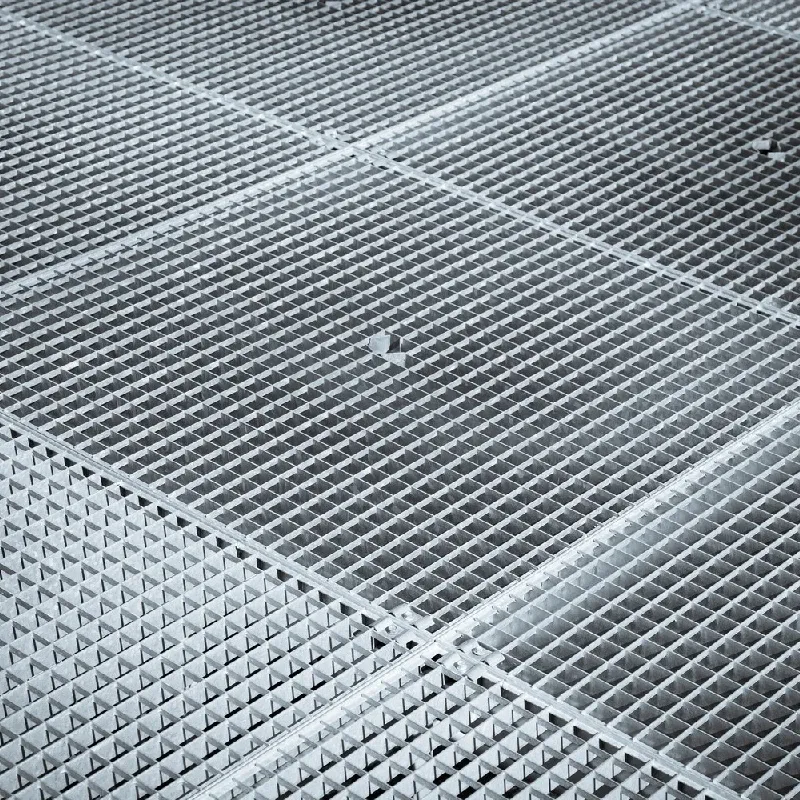

bar grating catalog

Understanding Bar Grating An Essential Component in Industrial Applications

Bar grating, also known as metal grating or simply grating, is a critical construction element utilized in a variety of industrial and architectural applications. It consists of a series of parallel bars or rails that are spaced apart to allow for the passage of light, air, and water while providing a strong and stable surface for walking, vehicular traffic, or industrial equipment.

One of the key attributes of bar grating is its versatility. It can be fabricated from various materials including steel, aluminum, and fiberglass, making it suitable for different environments and loads. Steel bar grating, for instance, is known for its durability and strength, making it ideal for heavy-duty applications in industrial plants, warehouses, and larger structures. The anti-slip surface of steel grating also enhances safety in areas prone to spills or increased foot traffic.

Understanding Bar Grating An Essential Component in Industrial Applications

Bar grating is not only functional but also economical. It is easy to install and requires minimal maintenance, making it an attractive option for many contractors and facility managers. The open design reduces weight while still providing the necessary structural support, which can lead to cost savings in both materials and shipping. Furthermore, any fumes or heat generated from machinery or industrial processes can escape through the grating, contributing to a safer and more efficient working environment.

bar grating catalog

Another vital aspect of bar grating is its application in drainage systems. Grating can be used to cover drainage channels, allowing for the free flow of water while preventing debris from entering and obstructing the system. This helps in maintaining clean environments, particularly in areas exposed to heavy rainfall or industrial runoff. By integrating bar grating in drainage solutions, businesses can protect their facilities and surrounding areas from flooding and other water-related issues.

In addition to its traditional uses, bar grating can also be customized to fit specific needs. Manufacturers often offer various finishes, coatings, and treatments to enhance the performance of the grating. For example, powder coating or galvanization can greatly improve corrosion resistance, making it suitable for use in harsh environments such as chemical plants, offshore sites, and coastal regions.

Furthermore, with the advent of advanced manufacturing techniques, bar grating can be engineered for specific load-bearing capacities and even aesthetic preferences. Designers and architects can collaborate with grating manufacturers to develop custom solutions that meet both functional and visual requirements.

In conclusion, bar grating is an indispensable element in modern construction and industrial operations. Its strength, versatility, and safety features, along with cost efficiency, make it a favored choice in a multitude of applications. As industries continue to evolve, the demand for innovative and reliable solutions like bar grating will undoubtedly grow, solidifying its role as a fundamental component in building and engineering practices across the globe. Whether for flooring, drainage systems, or safety barriers, bar grating remains a symbol of functionality and design in contemporary infrastructure.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025