- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Understanding the Weight of Aluminum Grating for Various Applications

Understanding Aluminum Grating Weight Characteristics, Benefits, and Applications

Aluminum grating is a popular choice in various industrial and commercial applications due to its lightweight properties, durability, and resistance to corrosion. Grates are essential for walkways, platforms, and drainage systems, offering both practicality and safety. This article explores the weight characteristics of aluminum grating, its advantages, and its diverse applications.

Characteristics of Aluminum Grating

Aluminum grating is made from aluminum alloys, which are known for their strength-to-weight ratio. The weight of aluminum grating is significantly lower than steel or other materials, making it easier to transport and install. The weight of aluminum grating can vary based on several factors, including the dimensions of the grating panels, the type of aluminum alloy used, and the design of the grating itself.

Typically, aluminum grating panels come in various thicknesses and load ratings. For instance, common thicknesses range from 1 inch to 3 inches, while load ratings can vary depending on the intended use. When considering the weight of aluminum grating, it is essential to take into account these dimensions alongside the design, such as whether it’s a bar grating, plank grating, or expanded metal grating.

Benefits of Lightweight Aluminum Grating

1. Ease of Installation The lightweight nature of aluminum grating makes it easier for workers to handle, reducing labor costs and time required for installation. The lighter weight also lowers the structural load on supports, making it a preferred option for elevated walkways and platforms.

2. Corrosion Resistance Aluminum naturally forms a protective oxide layer that prevents rusting and corrosion. This feature is particularly beneficial in environments that expose grating to moisture or chemicals, such as wastewater treatment facilities or marine applications.

3. Cost-Effectiveness Although the initial investment in aluminum grating may be higher than other materials, the long-term savings in maintenance and replacement costs due to its durability and resistance to corrosion make it a cost-effective solution.

4. Aesthetic Appeal Aluminum grating can be finished with various coatings and colors, enhancing its appearance in architectural applications. This versatility allows it to blend seamlessly into different environments, from industrial spaces to landscaped areas.

aluminum grating weight

5. Recyclability Aluminum is 100% recyclable, which contributes to its appeal from an environmental perspective. Using aluminum grating aligns with sustainability goals by promoting the use of recycled materials and reducing waste.

Applications of Aluminum Grating

Aluminum grating is used in various sectors, thanks to its lightweight and durable characteristics. Some of the primary applications include

1. Industrial Walkways and Platforms Its strength and slip-resistant surface make aluminum grating an excellent choice for demanding industrial environments, such as factories, manufacturing plants, and warehouses.

2. Drainage Systems Aluminum grating is often utilized in drainage applications, providing a strong, lightweight solution that allows for water drainage while allowing for ventilation.

3. Transportation and Aviation In airports and transport terminals, aluminum grating is frequently used for walkways, baggage handling areas, and security checkpoints because it is easy to maintain and meets safety standards.

4. Food and Beverage Industry The corrosion resistance and easy cleaning capabilities of aluminum grating make it suitable for food processing plants and commercial kitchens, where hygiene is paramount.

5. Marine and Coastal Applications The lightweight and corrosion-resistant properties make aluminum grating ideal for docks, piers, and other marine infrastructure that experience exposure to saltwater.

Conclusion

In summary, aluminum grating offers an array of benefits owing to its lightweight structure and durability. Understanding the weight and characteristics of aluminum grating is vital for selecting the right type for specific applications. Industries continue to embrace aluminum grating for its practicality, safety measures, and aesthetic options. As we move towards a more sustainable future, the choice of aluminum as a construction material for grating will likely expand, solidifying its role in various sectors.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

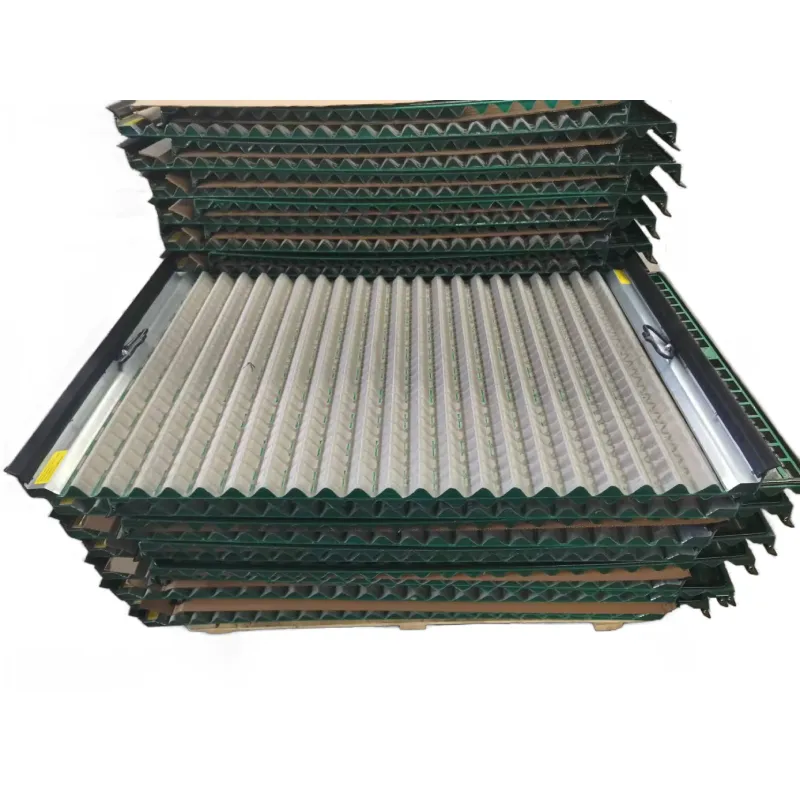

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025