- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

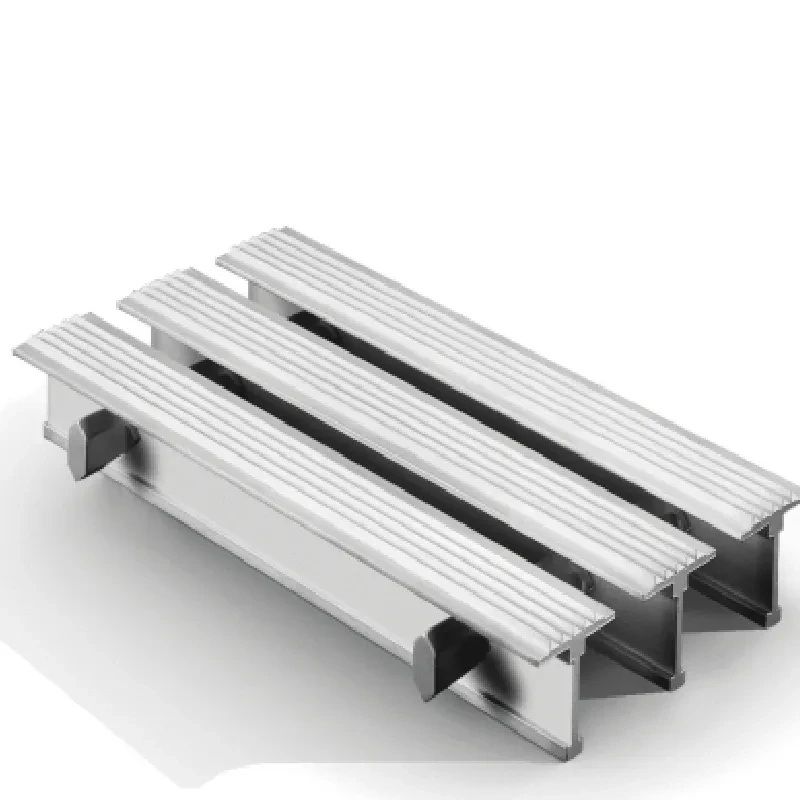

Determining the Weight of Aluminum Grating for Various Applications and Installations

Understanding Aluminum Grating Weight A Comprehensive Overview

Aluminum grating is a widely used material across various industries, known for its lightweight yet robust characteristics. In applications ranging from flooring to safety barriers and drainage covers, understanding the weight of aluminum grating is essential for both structural integrity and logistical efficiency. This article delves into the factors influencing aluminum grating weight, its applications, and the importance of selecting the right specifications for your project.

What is Aluminum Grating?

Aluminum grating is a type of material created by assembling aluminum bars or rods into a grid-like structure. It can be used in various forms, including heavy-duty, light-duty, and decorative grates, according to the application requirements. Its inherent properties—such as corrosion resistance, strength-to-weight ratio, and maintenance ease—make aluminum grating a popular choice for both industrial and commercial purposes.

Factors Affecting Weight

The weight of aluminum grating can vary significantly based on several factors

1. Type of Grating Different types of grating, such as welded, pressed, or molded, possess varying weights due to differences in manufacturing processes and structural configurations. For instance, welded grating typically offers higher load-bearing capacities while maintaining a relatively low weight.

2. Material Thickness The thickness of the aluminum bars used in grating directly affects its weight. Thicker bars provide additional strength and support but also contribute to increased weight. Conversely, thinner bars reduce weight, which can be beneficial for applications requiring portability.

3. Bar Spacing The distance between the bars (spacing) also plays a crucial role in determining weight. Wider spacing reduces the overall material used, thus lowering the grating's weight. However, it’s critical to ensure that the spacing meets the load requirements of the intended application.

4. Finish and Coating Some aluminum gratings come with protective coatings or finishes that can add minimal weight but provide enhanced durability and corrosion resistance. The choice of finish can thus be a strategic decision balancing weight, protection, and aesthetics.

Determining Weight

To calculate the weight of aluminum grating, you can use a straightforward formula

\[ \text{Weight} = \text{Volume} \times \text{Density} \]

aluminum grating weight

The density of aluminum is approximately 2.7 grams per cubic centimeter (g/cm³). By determining the volume of the grating by multiplying its area by its thickness, you can arrive at an accurate estimation of its weight.

For example, if you have a grating panel that measures 1 meter by 1 meter and is 2 cm thick, the volume would be calculated as follows

- Area = 1 m² - Thickness = 0.02 m - Volume = Area × Thickness = 1 m² × 0.02 m = 0.02 m³

Now, converting cubic meters to cubic centimeters (1 m³ = 1,000,000 cm³)

- Volume = 20,000 cm³

Finally, multiply the volume by the density of aluminum

- Weight = 20,000 cm³ × 2.7 g/cm³ = 54,000 grams or 54 kg.

Applications of Aluminum Grating

Aluminum grating is versatile, making it suitable for numerous applications

- Walkways and Platforms Its lightweight nature allows for easy installation, while its strength ensures safety under foot traffic. - Drainage Covers Resistant to corrosion, aluminum grating is ideal for places exposed to water, making it a common choice for drainage systems. - Architectural Elements Decorative aluminum grating can enhance building aesthetics while providing functionality in facades and railings.

Conclusion

Understanding aluminum grating weight is vital for engineers, architects, and procurement managers. It is crucial to evaluate specifications and characteristics tailored to your project requirements. By considering type, thickness, spacing, and finishes, you can ensure that you choose the appropriate aluminum grating solution that balances lightweight properties with the necessary strength for your application. Whether for industrial use or aesthetic design, aluminum grating proves to be a reliable choice that meets diverse needs while keeping weight to a minimum.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025