- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

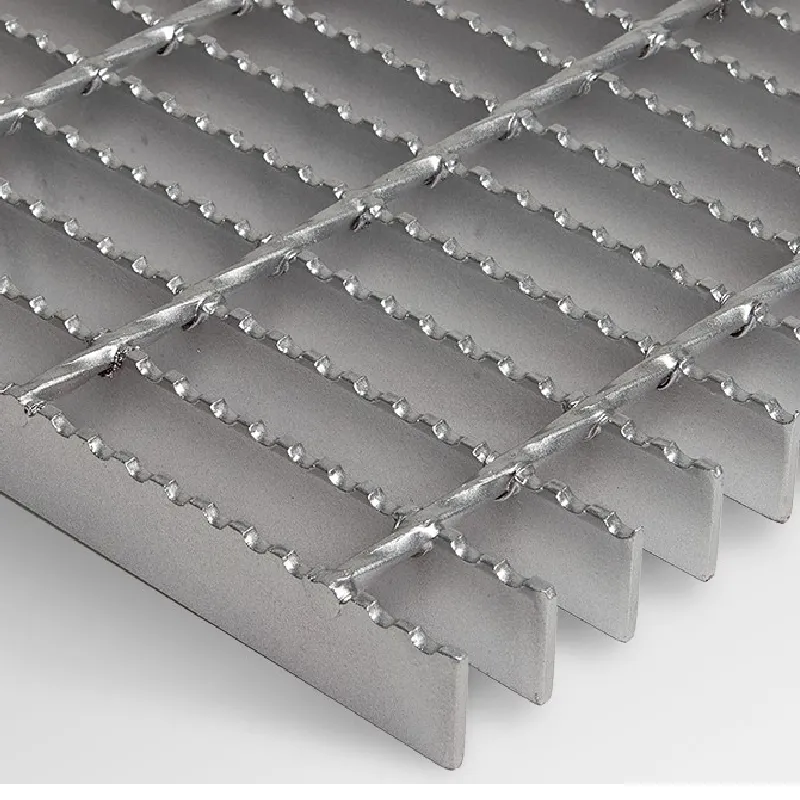

aluminum grating manufacturers

The Rise of Aluminum Grating Manufacturers A Detailed Overview

In recent years, the demand for aluminum grating has surged across various industries, leading to the evolution of numerous aluminum grating manufacturers

. These manufacturers play a crucial role in the production of lightweight, durable, and corrosion-resistant grating solutions, which are essential for a myriad of applications, including construction, industrial, and architectural projects.Aluminum grating is made from aluminum alloys, offering several advantages over traditional materials such as steel and fiberglass. First and foremost, its lightweight properties make aluminum grating easy to handle, transport, and install. This characteristic is especially beneficial in construction sites where efficiency and time are critical. Furthermore, the high strength-to-weight ratio of aluminum ensures that the grating can support significant loads while minimizing structural strain.

One of the standout features of aluminum grating is its excellent corrosion resistance. Unlike steel, which can rust when exposed to moisture and chemicals, aluminum forms a protective oxide layer that shields it from environmental harm. This property makes aluminum grating particularly suitable for use in corrosive environments, such as chemical plants, marine applications, and wastewater treatment facilities. The longevity of aluminum grating not only reduces maintenance costs but also extends the life of structures, making it a smart investment for businesses.

The versatility of aluminum grating has also contributed to its growing popularity. Manufacturers offer various types of aluminum grating, including welded, swaged, and pressed styles, each tailored to specific requirements. Additionally, these gratings can be customized in terms of size, load capacity, and surface treatment. This adaptability allows architects and engineers to integrate aluminum grating into their designs seamlessly, improving both functionality and aesthetics.

aluminum grating manufacturers

In the competitive landscape of aluminum grating manufacturing, several companies have emerged as leaders. These manufacturers prioritize innovation, investing in advanced technologies to improve production efficiency while maintaining high standards of quality. Many have adopted environmentally conscious practices, utilizing recycled aluminum in their processes, thus reducing their carbon footprint and appealing to sustainable practices in construction.

Moreover, the global trend toward urbanization and infrastructure development has fueled the growth of the aluminum grating market. As cities expand and the construction of new buildings, walkways, and industrial facilities increases, the need for reliable, durable materials like aluminum grating becomes more pronounced. Manufacturers are also exploring opportunities in emerging markets, where rapid development is coinciding with a rise in demand for durable yet lightweight construction materials.

As the market continues to evolve, aluminum grating manufacturers are also focusing on enhancing the safety and usability of their products. Anti-slip coatings and custom designs are being developed to meet specific industry standards, ensuring that aluminum grating not only meets functional requirements but also adheres to safety regulations.

In conclusion, aluminum grating manufacturers are at the forefront of providing innovative, sustainable, and reliable solutions for various industries. With their commitment to quality and adaptability, they are well-positioned to meet the growing needs of the market. As businesses increasingly recognize the benefits of aluminum grating, its role in construction and industry will undoubtedly continue to expand, solidifying its place as a vital component in modern infrastructure development. As we look to the future, the continuous evolution of aluminum grating manufacturing promises exciting opportunities for innovation and growth in this dynamic field.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025