- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Top Aluminum Grating Producers for High-Quality Grating Solutions and Custom Designs

Understanding the Role of Aluminum Grating Manufacturers

Aluminum grating has become an indispensable component in various industries, offering significant advantages such as durability, lightweight properties, and excellent corrosion resistance. These characteristics make aluminum grating a preferred choice for applications ranging from industrial flooring and walkways to drainage covers and trench grates. This article delves into the significance of aluminum grating manufacturers and the various factors to consider when selecting one for your needs.

The Importance of Aluminum Grating

Aluminum grating is utilized across a broad spectrum of sectors, including construction, automotive, aerospace, and chemical processing. Its unique properties provide safety and efficiency in environments where heavy loads, pedestrian traffic, and exposure to harsh weather conditions are common. Since aluminum is lighter than other metals like steel, it reduces the overall weight of structures without compromising strength and load-bearing capacity.

One of the key benefits of aluminum grating is its resistance to corrosion, especially in environments exposed to moisture and chemicals. Unlike traditional steel grating, which may rust and deteriorate over time, aluminum remains intact, extending the lifespan and reducing maintenance costs of infrastructure.

The Role of Manufacturers

Aluminum grating manufacturers play a critical role in the supply chain by producing high-quality products tailored to specific industry needs. These manufacturers utilize modern fabrication techniques, ensuring that their products meet stringent industry standards and regulatory requirements. Additionally, they often offer customization options, allowing clients to select specific dimensions, thicknesses, and finishes that suit their particular applications.

When evaluating manufacturers, the following factors should be considered

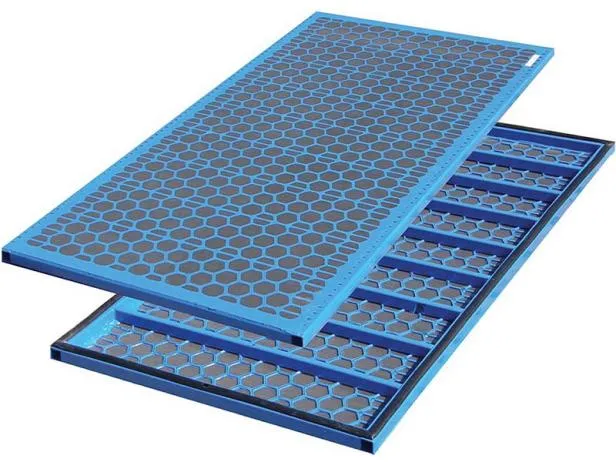

aluminum grating manufacturers

1. Quality Assurance A reputable manufacturer will have robust quality control processes in place. This includes rigorous testing of materials and finished products to ensure they meet or exceed industry standards. Certifications and compliance with safety regulations are also good indicators of a manufacturer’s commitment to quality.

2. Product Range Different applications require varied types of grating. A reliable manufacturer should provide a broad selection, including various sizes, shapes, and designs. This versatility ensures that customers can find the right product to meet their unique requirements.

3. Innovation and Technology The best manufacturers invest in the latest technology and research to improve their products continuously. This not only enhances the performance and longevity of the grating but also integrates advanced designs that can accommodate specific needs, such as slip resistance and aesthetics.

4. Customer Support Excellent customer service is vital in the manufacturing process. A trustworthy manufacturer provides comprehensive support, from initial inquiries and product selection to post-purchase assistance. Responsive communication and technical advice can significantly enhance the customer experience and ensure that projects proceed smoothly.

5. Sustainability As industries become more environmentally conscious, many manufacturers are adopting sustainable practices. Aluminum is 100% recyclable, and manufacturers that emphasize eco-friendly production methods contribute to a more sustainable future. Choosing a manufacturer with a commitment to sustainability can help companies meet their environmental goals.

Conclusion

In conclusion, the importance of aluminum grating manufacturers cannot be overstated. Their contributions to various industries facilitate the creation of safer, more efficient infrastructures that stand the test of time. When selecting a manufacturer, it’s essential to consider factors such as quality assurance, product range, technological innovation, customer support, and sustainability practices. By doing so, businesses can ensure they partner with a reputable company capable of meeting their specific needs and contributing positively to their operations. Aluminum grating not only enhances safety and functionality but also represents a forward-thinking choice in contemporary materials engineering. As industries evolve and demands increase, the role of manufacturers will remain central to the successful implementation of aluminum grating solutions.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025