- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

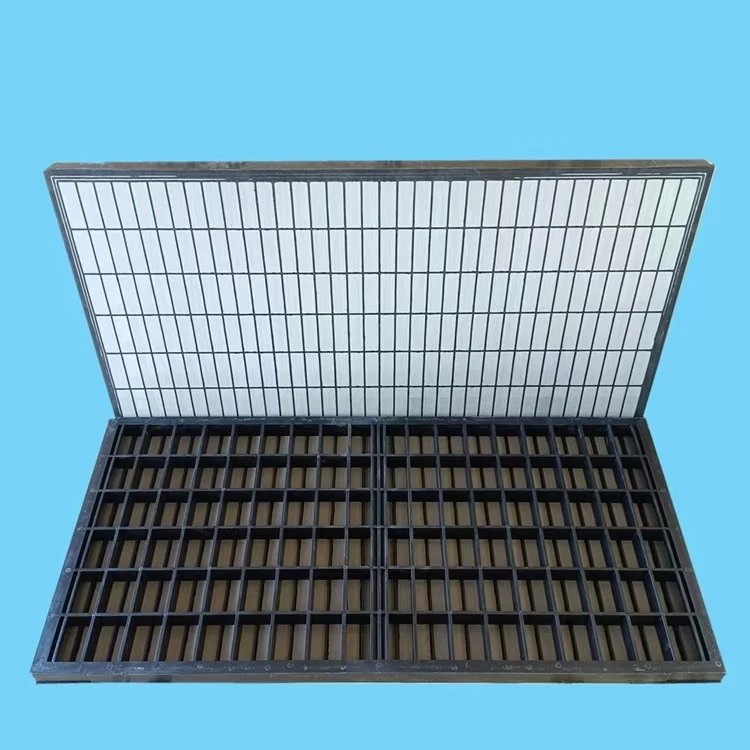

Calculating the Weight of Aluminum Bar Grating for Industrial Applications

Understanding Aluminum Bar Grating Weight

Aluminum bar grating is a type of flooring material made from aluminum bars that are set parallel to each other and are connected by perpendicular bars. This construction allows for a highly durable, lightweight, and corrosion-resistant solution that is widely used in various industrial and architectural applications. One of the key aspects to consider when working with aluminum bar grating is its weight, which influences both installation procedures and structural considerations.

The Composition of Aluminum Bar Grating

Typically, aluminum bar grating is manufactured from high-strength alloys, which contribute to its lightweight characteristics. The common alloy used is 6061-T6, which is known for its excellent mechanical properties and resistance to corrosion. The bars come in different height and spacing configurations, which makes it possible to customize grating to meet specific load-bearing requirements.

Weight Considerations

When discussing the weight of aluminum bar grating, it is essential to understand that the weight is determined by several factors, including dimensions, bar thickness, spacing, and the overall design. Aluminum grating generally weighs between 1.5 to 3.0 pounds per square foot. This is significantly lighter compared to other grating materials like steel or fiberglass, which can make aluminum a preferable option in many scenarios.

Benefits of Lightweight Design

aluminum bar grating weight

The lightweight nature of aluminum bar grating offers several advantages. Firstly, it simplifies the installation process, allowing for easier handling and transportation. This can reduce labor costs and time spent on installation. Secondly, the reduced weight can lower the requirements for supporting structures, allowing for a more efficient use of materials and design. This can be particularly advantageous in applications where weight restrictions are essential, such as on rooftops or in elevated platforms.

Load-Bearing Capacities

Despite its lightweight characteristics, aluminum bar grating is designed to support a considerable amount of weight. The load-bearing capacity depends on the specific configuration of the grating, including the bar spacing and thickness. Engineers often calculate the expected load requirements to select the appropriate grating specifications. In many cases, aluminum bar grating can support loads ranging from pedestrian traffic to heavy machinery, making it versatile for various applications.

Applications in Industries

Aluminum bar grating is commonly used in many industries, including manufacturing, oil and gas, food processing, and wastewater treatment. It is often utilized for walkways, platforms, stair treads, and drainage covers. Its corrosion resistance makes it particularly useful in environments exposed to moisture or chemicals. Additionally, the open design of bar grating allows for efficient drainage of liquids, reducing slip hazards.

Conclusion

In conclusion, understanding the weight of aluminum bar grating is crucial for engineers, architects, and contractors. Its lightweight properties, combined with strength and versatility, make it an ideal choice for countless applications. Recognizing the factors that influence its weight and load-bearing capacity can lead to better design choices and successful project outcomes. As industries continue to seek efficient, durable, and sustainable materials, aluminum bar grating will remain a popular choice due to its numerous advantages.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025