- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Exploring the Effects of 1% Bar Grating on Light Diffraction Patterns

Understanding 1% Bar Grating An Essential Component in Modern Engineering

In the realm of engineering and architectural design, the term bar grating frequently comes into play, especially when discussing materials and structures that prioritize strength, safety, and efficiency. One specific type of bar grating worth exploring is 1% bar grating, known for its unique properties and applications. This article delves into what 1% bar grating is, its properties, uses, and the advantages it brings to various engineering fields.

What is 1% Bar Grating?

Bar grating is a type of material made from flattened steel or other metals, usually manufactured in a grid pattern. This structure is characterized by a series of parallel bars spaced evenly apart, forming a series of openings or slots that allow for air, light, or liquid to pass through. The 1% designation in 1% bar grating refers to the percentage of open area relative to the total surface area of the grating. In this case, the grating has an open area proportion of approximately 1%, which influences its load-bearing capabilities and applications.

Properties of 1% Bar Grating

The primary features that distinguish 1% bar grating include its strength, durability, and lightweight nature. The design allows it to support various loads while minimizing the material required for manufacturing. The steel bars typically undergo treatments to resist rust and corrosion, making them suitable for outdoor applications or environments with high exposure to moisture.

Another notable property of 1% bar grating is its slip resistance. The surface can be treated or designed to provide enhanced traction, making it a popular choice for flooring in industrial settings and public spaces. Additionally, the open area can aid in drainage, allowing liquids to flow through quickly, reducing the risk of pooling or flooding, particularly in high-traffic zones.

Applications of 1% Bar Grating

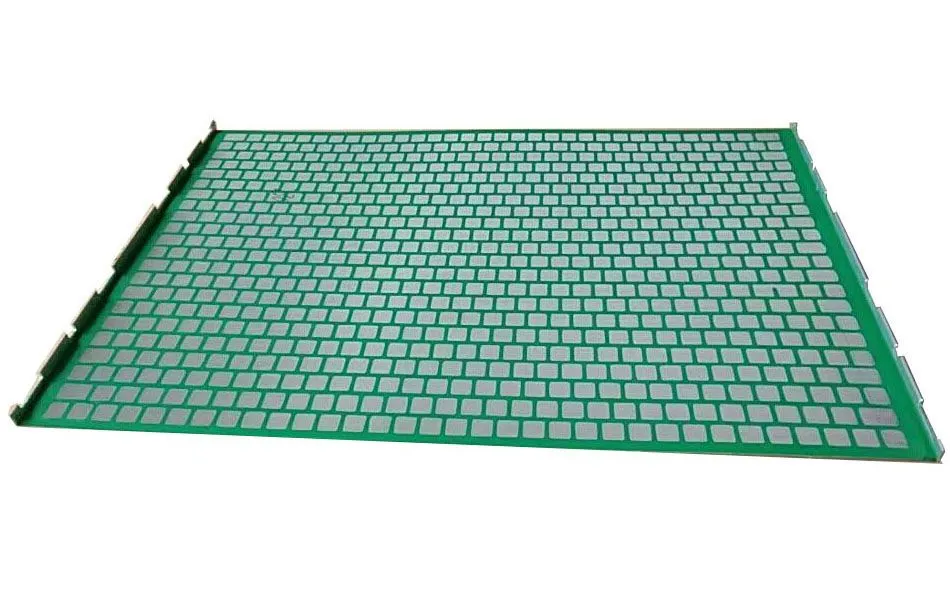

1 bar grating

1% bar grating finds its applications in diverse sectors, including construction, manufacturing, and transportation. In construction, it is often used for walkways, platforms, and stair treads where both safety and functionality are paramount. The grating's ability to allow for ample airflow means it can also be utilized in ventilation systems, ensuring a continuous flow of air and assisting in temperature regulation.

In the manufacturing sector, 1% bar grating is instrumental in machinery platforms and workstations, providing a sturdy surface that can withstand heavy equipment and personnel traffic. Its slip-resistant properties make it pivotal in environments where liquids or contaminants might be present, ensuring the safety of workers.

Moreover, 1% bar grating can be found in transportation infrastructure. It may be used in subways, train stations, and platforms where both strength and visibility are essential. By allowing light to filter through, it maintains visibility while also providing a solid footing for pedestrians.

Advantages of 1% Bar Grating

The advantages of utilizing 1% bar grating are numerous. Firstly, its lightweight design facilitates easier transport and installation, reducing labor costs and time spent on projects. Secondly, due to its open area design, it enhances drainage and minimizes the risk of puddling, which can be a significant hazard in places like industrial warehouses or outdoor structures.

Moreover, the long-term durability means that once installed, 1% bar grating generally requires minimal maintenance, translating to further savings over time. Lastly, the aesthetic appeal of bar grating in modern architectural designs makes it a favorable choice amongst architects and builders.

In conclusion, 1% bar grating is an essential component in various facets of engineering and design, offering a blend of strength, safety, and functionality. As industries continue to evolve, the demand for such innovative solutions will undoubtedly persist, cementing the role of 1% bar grating in shaping the infrastructures of tomorrow.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025