- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Optimizing Grating Weight for Enhanced Performance in 19% W 4 Application Settings

Understanding the Impact of 19% W 4 Grating Weight in Structural Applications

In various structural applications, the materials chosen significantly influence the performance, durability, and overall effectiveness of the constructions. One of the critical factors that engineers and architects consider is the weight of the elements used. This article delves into the implications of a grating holding a weight of 19% W 4, exploring its significance in different applications and the engineering principles involved.

Definition and Composition

Before delving into the technical aspects, it's essential to clarify what a grating is. A grating typically refers to a framework of bars or rods that create a grid-like structure. In engineering, gratings are vital for flooring, sidewalks, and any surface that requires strength without excessive weight. The term 19% W 4 can be deciphered in the context of its material and structural composition. The 'W' might denote the weight factor, whereas '4' could represent a code for structural integrity or the load-bearing capacity of the grating.

Importance of Grating Weight

The weight of grating plays a crucial role in its application. In architectural design, lighter materials reduce the overall dead load of a structure, allowing for more versatility in the design and potentially lowering construction costs. When dealing with a grating that has a weight defined as 19% W 4, it might be an indicator that the material has been optimized for weight without compromising strength.

1. Structural Efficiency A grating that weighs only 19% of a baseline weight can lead to greater structural efficiency. Engineers can design buildings with higher load capacities, making them safer and more stable while using less material. This efficiency is paramount in high-rise buildings, where weight savings are critical in preventing construction complications.

2. Cost-Effectiveness Lighter gratings can reduce shipping and handling costs and lead to a decrease in labor costs during installation. For example, if contractors can manipulate and install grating modules more easily due to their lighter weight, the time and resources spent on labor can be significantly reduced.

3. Environmental Considerations Reduced material usage often leads to a smaller carbon footprint for construction projects. A grating designed with a weight of 19% W 4 can contribute to more sustainable construction practices, making it a preferable choice for environmentally-conscious projects.

Engineering Considerations

19 w 4 grating weight

When designing structures with gratings, engineers must consider several factors

- Load Distribution The grating must be able to support dynamic loads (like people and vehicles) and static loads (such as machinery and equipment). The 19% W 4 specification would require precise calculations to ensure that the grating can handle expected loads without buckling or failing.

- Material Selection The material from which the grating is made affects both its weight and strength. Common materials include steel, aluminum, and fiberglass. Each has its own advantages and disadvantages regarding weight, corrosion resistance, and lifespan.

- Safety Standards Structural integrity must align with local building codes and safety regulations. The weight and design of the grating should comply with these standards to ensure the safety of users.

Applications

The implications of a 19% W 4 grating weight can be observed across various industries

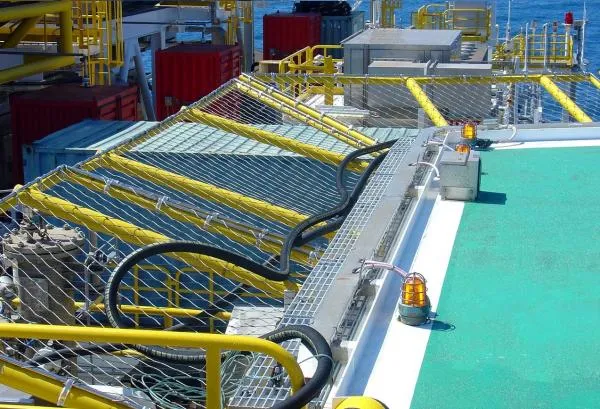

- Construction From walkways to balconies, lighter gratings facilitate quicker setups without compromising safety. - Transportation In railways and bridge designs, the combination of weight capacity and lighter materials can increase lifespan and reduce maintenance. - Industrial Factories often require grating for safety and ventilation. Lightweight options that maintain strength are ideal for ensuring operational efficiency and safety.

Conclusion

In summary, understanding the implications of a grating with a weight specification like 19% W 4 is crucial for architects and engineers. It highlights the balance between weight, cost, and structural efficiency. As engineering progresses, there is a continuous push towards optimizing materials for better performance, sustainability, and safety. Ultimately, the goal is to create structures that not only meet the demands of modern use but also stand the test of time.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025