- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

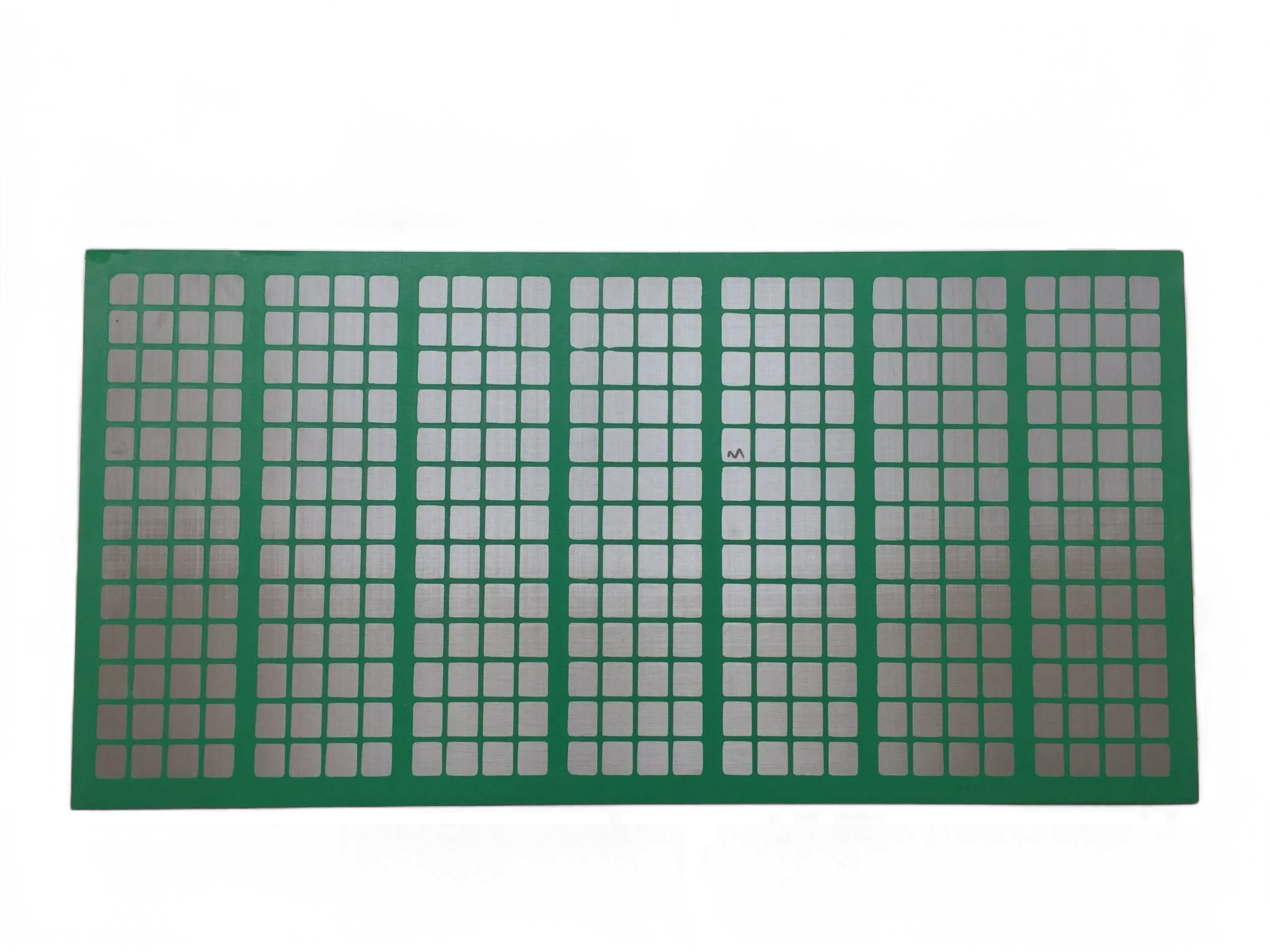

19 Percent Weight Distribution for Four-Grating System Analysis and Optimization Techniques

Understanding the Significance of 19% W 4 Grating Weight in Material Engineering

In the realm of material engineering, specifications and measurements play a crucial role in determining the performance and applicability of various materials. One such specification that has garnered attention is the 19% W 4 grating weight. This article aims to elucidate the implications and significance of the 19% W 4 grating weight, its applications, and how it affects the performance of materials in engineering and construction.

What is Grating Weight?

Grating weight refers to the amount of load or weight distribution that a grating can support without compromising its structural integrity. Gratings are typically used in flooring, walkways, and platforms, providing essential accessibility while ensuring safety in various environments. The “19% W 4” designation typically includes both the weight distribution capacity and the specific characteristics of the grating material.

Breaking Down the Specifications

The 19% refers to the weight percentage of a particular material composite utilized in the grating's construction. A higher weight percentage can indicate a denser, potentially stronger material, enhancing the grating's load-bearing capabilities. The W 4 often corresponds to a specific type of grating classification. This could denote the width or spacing of the bars and the overall structural design, which are meticulously engineered to ensure safety, functionality, and durability.

Importance of Grating Weight in Material Selection

The choice of grating weight plays a significant role in various industries such as construction, oil and gas, food processing, and pharmaceuticals. In environments where chemical interaction, high foot traffic, or heavy machinery is prevalent, selecting the correct grating weight ensures that the structure is not only safe but also lasts longer, reducing maintenance costs.

1. Safety In industrial settings, heavy loads are commonplace. Selecting a grating with appropriate weight capabilities ensures that it can withstand weight stress without deformation or failure, which is crucial for worker safety.

2. Durability The longevity of the materials used directly correlates with their weight capacities. A 19% W 4 grating weight specification indicates a designed resilience against the elements and continuous use.

19 w 4 grating weight

3. Cost-Effectiveness Choosing the right grating can influence overall costs. While materials with higher weight specifications may come at a higher upfront cost, their durability and the potential reduction in maintenance and replacement needs make them economically viable over the long term.

Applications of 19% W 4 Grating Weight

A variety of industries harness the attributes of 19% W 4 grating weights, including

- Industrial Platforms Often used in warehouses and production facilities, these gratings can support heavy machinery and allow for safe worker movement.

- Walkways and Stairs In public and commercial buildings, gratings that meet the 19% W 4 requirements provide safe access while reducing the weight burden on supporting structures.

- Chemical Processing Facilities Materials that prevent corrosion and provide high load capacities are essential in these settings to handle both weight and chemical exposure, highlighting the importance of choosing the right grating weight.

- Architectural Design Modern architecture often employs gratings not just for functional purposes but as design elements, necessitating a balance between aesthetic appeal and structural integrity.

Conclusion

Understanding the implications of specifications such as the 19% W 4 grating weight is essential for professionals involved in material selection and engineering design. Accurate specifications not only ensure the safety and durability of structures but also enhance the overall efficiency and cost-effectiveness of projects across various sectors. As technology advances and materials science continues to evolve, the importance of such metrics will only grow, influencing future designs and applications in innovative ways. By choosing the appropriate grating weight and composition, engineers can construct safer and more reliable infrastructures that stand the test of time.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025