- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

19 w 4 bar grating

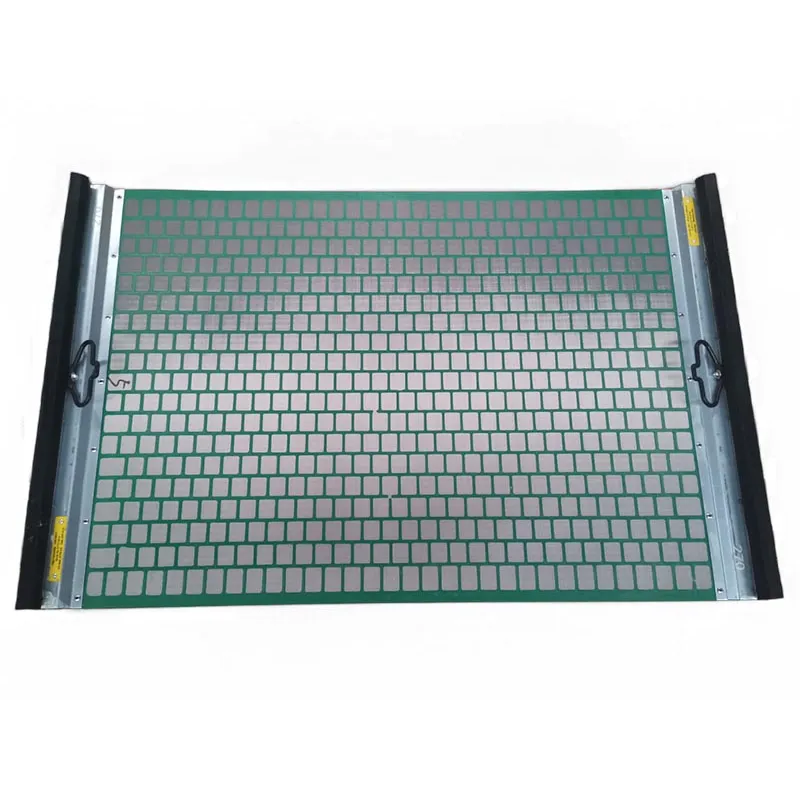

Understanding 19% W 4 Bar Grating A Comprehensive Overview

When it comes to industrial applications, the selection of the appropriate materials and fabrication techniques is crucial for ensuring both efficiency and durability. One such example is the 19% W (Welded) 4 Bar Grating. This type of grating is engineered to meet specific needs in various sectors, including construction, transportation, and more. In this article, we will delve into the characteristics, applications, advantages, and production methods related to 19% W 4 Bar Grating.

Characteristics of 19% W 4 Bar Grating

19% W 4 Bar Grating is characterized by its unique design that comprises four horizontal bars joined by vertical supports. The 19% refers to the weight percentage of the material used in making the grating, which significantly impacts its strength and load-bearing capabilities. Typically manufactured from steel or aluminum, this grating offers a balance between durability and weight, making it suitable for various loading conditions.

The spacing between the bars is critical because it affects both the ventilation and the ability to support loads. The spacing must adhere to specific industry standards to ensure safety and functionality, especially in high-traffic areas. Moreover, the grating is often treated with protective coatings to enhance corrosion resistance, thereby extending its lifespan.

Applications of 19% W 4 Bar Grating

The versatility of 19% W 4 Bar Grating makes it suitable for numerous applications. It is commonly used in flooring systems, walkways, platforms, and stair treads in industrial buildings, warehouses, and even commercial properties. The open design allows for excellent airflow and drainage, making it ideal for areas where moisture could be a concern.

Moreover, such grating is utilized in the automotive and transportation industries, particularly in pedestrian crossings and train stations, where safety and durability must be prioritized. Additionally, it serves as a support structure in various manufacturing processes where heavy machinery could put significant stress on flooring.

19 w 4 bar grating

Advantages of 19% W 4 Bar Grating

One of the primary advantages of 19% W 4 Bar Grating is its strength-to-weight ratio. By utilizing a well-engineered design with 19% weight material, manufacturers can create grating that can support substantial loads while minimizing excess weight. This characteristic is crucial in sectors that prioritize efficiency without compromising structural integrity.

Furthermore, the open design of the 4 Bar Grating allows for effective drainage, preventing the accumulation of water or debris. This feature is especially beneficial in outdoor applications, where weather conditions can vary. Another significant advantage is its ease of installation; the modular nature of the grating allows for quick assembly and customization on-site.

Production Methods

The production of 19% W 4 Bar Grating typically involves several stages, including material selection, cutting, welding, and finishing. High-quality raw materials are essential for achieving the desired strength and durability. Advanced fabrication techniques, such as laser cutting and precision welding, are often employed to create components that fit together seamlessly.

Once the grating is fabricated, finishing processes like galvanizing or painting can be applied to enhance corrosion resistance and improve appearance. Quality control measures are vital throughout production to ensure adherence to safety standards and performance criteria.

Conclusion

In summary, 19% W 4 Bar Grating stands out as a remarkable solution for a wide range of industrial applications. Its unique design offers an excellent balance between strength, efficiency, and versatility. With its various applications, advantages in installation and use, and a well-defined production process, it's no wonder that this type of grating has become a preferred choice across multiple industries. As industries continue to evolve, the demand for innovative solutions like 19% W 4 Bar Grating will likely increase, paving the way for further advancements in industrial materials and applications.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025