- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

1 1 4 bar grating

Understanding 1% 201% 4 Bar Grating A Comprehensive Overview

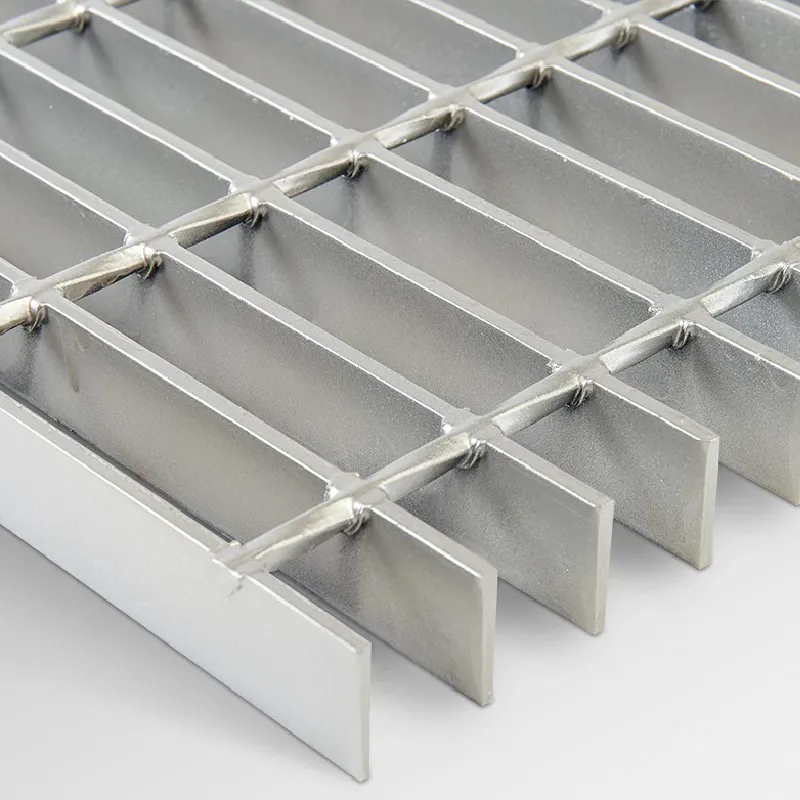

Bar grating is an essential structural element widely used in various industries, particularly in construction, manufacturing, and infrastructure projects. Among the many types of bar grating, 1% 201% 4 bar grating presents unique characteristics and advantages that make it a notable choice for engineers and architects. In this article, we will explore the features, applications, benefits, and installation processes associated with 1% 201% 4 bar grating.

What is Bar Grating?

Bar grating is a type of material made from a series of parallel bars that are welded together, creating a grid-like structure. This structure allows for the easy movement of air, light, and liquids while providing necessary load-bearing capabilities. Bar grating is typically manufactured from materials such as steel, aluminum, or fiberglass, making it suitable for a variety of applications.

Features of 1% 201% 4 Bar Grating

The designation of 1% 201% 4 bar grating refers to specific dimensions and spacing between the bars, which can greatly influence its functionality. The “1%” can represent the height or thickness of the bar, measured in millimeters, conversely, enunciated as a percentage of total height. The “201%” likely indicates the spacing in millimeters or inches between each bar, which is crucial for load distribution and pedestrian safety. The presence of “4” typically denotes the spacing of the cross bars, which add to the grating's strength and stability. These specifications can play a crucial role in determining the appropriate use of the grating in various settings.

Applications of 1% 201% 4 Bar Grating

Due to its strength and lightweight nature, 1% 201% 4 bar grating has a wide range of applications. Common uses include

1. Walkways and Platforms It provides a safe and stable walking surface for pedestrians in industrial settings, warehouses, and construction sites. 2. Drainage Covers The design allows for effective drainage and can carry substantial loads without compromising its integrity.

3. Stair Treads The nature of the grating allows for slip-resistant surfaces, making it an excellent option for stairs in commercial and industrial buildings.

4. Ventilation Grilles The space between the bars promotes airflow, making it ideal for ventilation systems in factories and industrial areas.

5. Support Structures Its strength and rigidity make it suitable for supporting heavy machinery and equipment in manufacturing plants.

Benefits of 1% 201% 4 Bar Grating

1 1 4 bar grating

The selection of 1% 201% 4 bar grating over other types comes with several benefits, including

- Durability Made from robust materials that can withstand harsh conditions, it offers longevity in service. - Ease of Maintenance Its open design simplifies maintenance, allowing for easy cleaning and inspection.

- Lightweight yet Strong Despite being lightweight, it can bear significant loads, which makes it an efficient choice for various applications.

- Customizability Manufacturers often offer customizable options, allowing engineers to specify dimensions to suit particular project needs.

- Cost-Effective The balance of affordability and durability makes it a cost-effective solution for various projects.

Installation Process

Installing 1% 201% 4 bar grating is relatively straightforward, but it requires proper planning and execution to ensure safety and functionality. Here are the typical steps involved

1. Site Preparation Clear and level the installation area to accommodate the grating. 2. Structural Support Ensure that there are adequate supporting beams or frames to secure the grating.

3. Cutting If necessary, cut the grating to fit the designated area using appropriate tools.

4. Securing Use bolts, screws, or welding to securely attach the grating to the support structure.

5. Safety Checks Conduct a thorough inspection to confirm stability and safety before usage.

Conclusion

1% 201% 4 bar grating represents an integral solution for numerous industrial and commercial applications. Its unique features, coupled with its versatility, make it a go-to material for engineers and construction professionals alike. Understanding its characteristics, benefits, and installation process can ensure that projects utilizing this grating type meet both operational and safety standards. As industries continue to evolve, the demand for efficient and effective materials like 1% 201% 4 bar grating will undoubtedly persist.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025