- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Exploring the Effects of 1% Grating on 4 Bar Systems in Optical Applications

Understanding 1% 201% 4 Bar Grating Significance, Applications, and Innovations

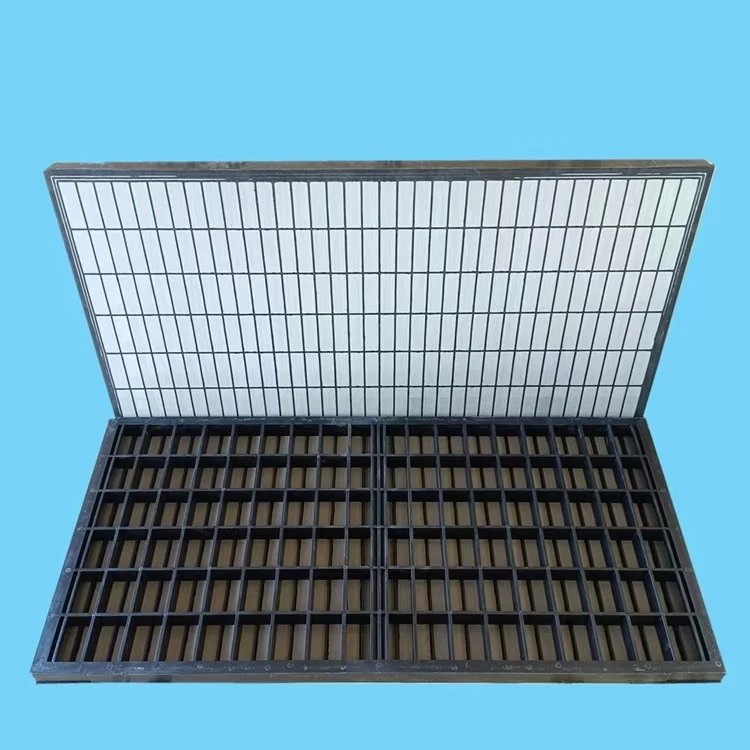

Bar gratings are an essential part of various engineering disciplines, providing structural support and safety features in a wide range of applications. The term 1% 201% 4 bar grating can be interpreted as a specific type of structured grating characterized by its design and material properties. This article delves into the significance, applications, and innovations of 1% 201% 4 bar grating.

Definition and Characteristics

Bar gratings are typically made from materials such as steel, aluminum, or fiberglass. They consist of a series of parallel bars, usually spaced at regular intervals. The notations in 1% 201% 4 bar grating may refer to specific technical parameters, including load-bearing capabilities, the percentage of material used, the depth of bars, or other relevant specifications.

The 1% typically indicates a modulus value or a strength percentage that signifies the material's efficiency under load. In large-scale construction and manufacturing, understanding the load-bearing capacity of materials is crucial for safety and longevity. The 201% could represent a performance metric or a specific design standard, suggesting that this type of grating can support up to 201% of a certain load under defined conditions. The 4 possibly refers to the number of bars or layers in the structure, further emphasizing the robustness of the grating.

Applications Across Industries

1% 201% 4 bar grating finds its utility in numerous industries

1. Construction and Civil Engineering Gratings are widely employed in building structures, walkways, and bridges, providing critical support and ensuring safety under foot and vehicle traffic. The high strength and calculated load capacities of 1% 201% 4 bar gratings make them ideal for environments with heavy traffic.

2. Manufacturing Facilities In industrial settings, grating is often utilized as flooring and platforms, where it minimizes the risk of slips and falls. The material's resistance to corrosion further extends its operational lifespan, particularly in facilities that process chemicals.

3. Transportation Gratings play a pivotal role in transportation infrastructure, such as railways and airport runways, where they serve as load-bearing surfaces that support significant weights.

1 1 4 bar grating

4. Environmental Management In wastewater treatment plants, bar gratings are used in filtration systems to manage debris while allowing fluids to pass through. The defined bar spacing in the 1% 201% 4 bar grating ensures efficient separation and filtration.

5. Safety and Security Bar gratings provide secure access points in various facilities, from commercial to governmental institutions. They can be designed with anti-slip surfaces and enhanced load capacities, ensuring safety for personnel and equipment.

Innovations in Bar Grating Design

The evolution of materials and design techniques has led to innovations in bar gratings. Recent advancements include

1. Composite Materials The use of composite materials in bar gratings offers benefits in terms of weight reduction, corrosion resistance, and enhanced load-bearing capacities. Composite gratings are particularly advantageous in environments prone to chemical exposure.

2. Custom Fabrication Technological developments in manufacturing have facilitated the custom fabrication of bar grating to meet specific project requirements. Clients can specify dimensions, load ratings, and surface finishes tailored to their unique needs.

3. Smart Grating Some companies are exploring the integration of sensors into bar gratings. These smart gratings can monitor stress levels, alerting facilities management to potential failures before they occur.

4. Sustainability With increasing emphasis on sustainability, some manufacturers are focusing on eco-friendly materials and production techniques. Biodegradable composites and recycled metals are paving the way for greener bar grating options.

Conclusion

The 1% 201% 4 bar grating epitomizes the importance of reliable materials in modern engineering. With their diverse applications spanning construction, manufacturing, and transportation, these gratings demonstrate the blend of strength, safety, and innovative design. As industries continue to evolve, so too will the technologies and methodologies behind bar gratings, ensuring they remain a fundamental aspect of engineering solutions in the years to come.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025