- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

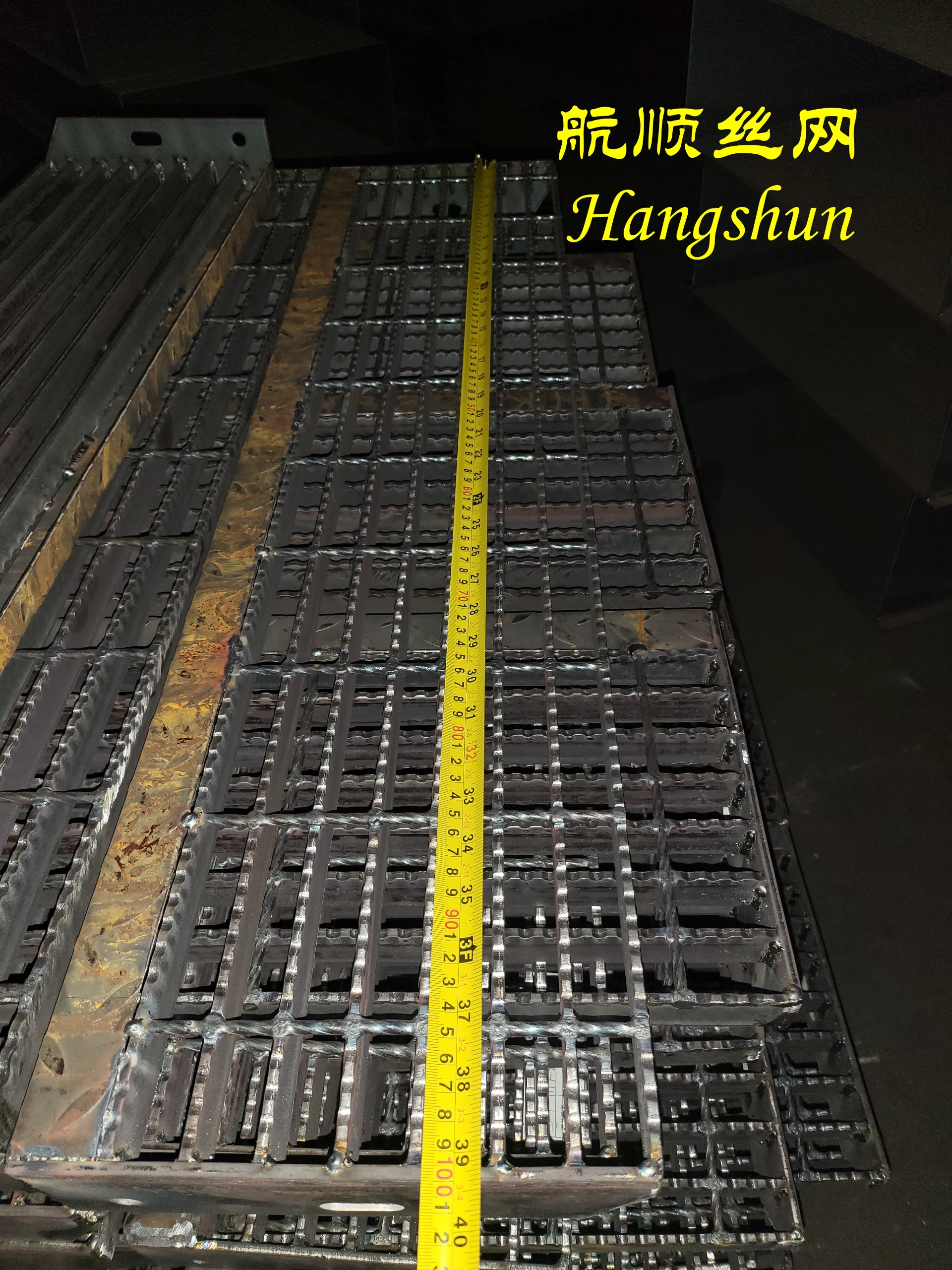

Design and Analysis of 1% 201% 4% Bar Gratings for Enhanced Optical Performance

Understanding the 1% 201% 4 Bar Grating An Overview

Bar grating systems play a pivotal role in various engineering applications, particularly in construction, manufacturing, and architectural design. Among these systems, the 1% 201% 4 bar grating stands out as a versatile solution suited for a multitude of purposes, emphasizing both strength and functionality.

To begin, it’s essential to comprehend what constitutes bar grating. Bar grating is a type of engineered product made from either metal or fiberglass. It is characterized by a grid-like framework consisting of parallel bars that are spaced apart, allowing for drainage and ventilation while also providing a sturdy walking surface. The designation 1% 201% 4 refers to specific configurations and characteristics of the bar grating, which can significantly influence its application and performance.

Understanding the 1% 201% 4 Bar Grating An Overview

Moving on to 201%, this could denote a specific type of material or grade utilized in the bar grating’s construction. Different materials, such as aluminum, steel, or fiberglass, confer distinct advantages aluminum is lightweight and resistant to corrosion, steel offers higher strength, and fiberglass is non-conductive and resistant to chemical damage. The suitability of the material choice often aligns with the environmental conditions and expected loads within the application area.

1 1 4 bar grating

The last figure, 4, typically represents the thickness or height of the bars used in the grating. Thicker bars inherently provide greater strength and durability, which is ideal for heavy-duty environments such as factories, warehouses, and loading docks. Conversely, thinner bars may be used in applications where weight and flexibility are prioritized, such as in pedestrian walkways and platforms.

Bar grating systems, including those conforming to the 1% 201% 4 specifications, are extensively utilized in several industries. In commercial construction, they contribute to safety by preventing slips and falls in wet or oily environments. In the manufacturing sector, bar gratings facilitate efficient drainage and airflow, keeping workspaces safe and sanitary.

Moreover, bar grating systems can be customized according to project specifications, making them highly adaptable. This customization encompasses variations in spacing, load capacities, and finishes, which can be tailored to meet the unique needs of any application.

In conclusion, the 1% 201% 4 bar grating system exemplifies a robust, versatile solution for modern engineering challenges. With its excellent performance characteristics, it effectively meets the demands of diverse applications while ensuring safety and efficiency. Whether for industrial use or architectural design, understanding the specifications and features of bar grating is essential for optimizing its effectiveness in various settings, thus making it a critical component in contemporary engineering practices.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025