- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

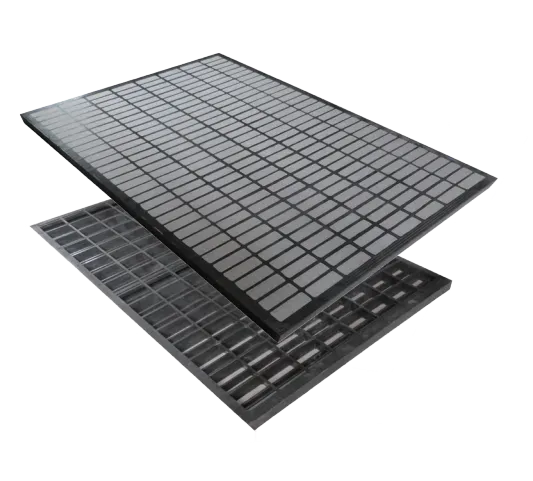

welded bar grating

Understanding Welded Bar Grating Applications, Benefits, and Manufacturing Process

Welded bar grating is an essential material used across various industries, providing numerous benefits in terms of safety, durability, and versatility. This article aims to explore what welded bar grating is, its applications, advantages, and the manufacturing process involved in creating this remarkable product.

What is Welded Bar Grating?

Welded bar grating is a type of flooring and structural support panel made from metal bars, typically steel, that are welded together at regular intervals to create a grid-like pattern. The main components of this structure are the load bars and the cross bars. The load bars are placed parallel to one another, while the cross bars are welded perpendicularly, forming an open grid with spaces between the bars. This design allows for efficient drainage and airflow while maintaining strength and stability.

Applications of Welded Bar Grating

Welded bar grating is widely used in various industrial and commercial applications due to its strong and durable nature. Some common applications include

1. Walkways and Platforms Welded bar grating is often used for walkways, platforms, and catwalks in industrial settings, providing safe passage for workers while allowing debris and water to fall through, thus reducing slip hazards.

2. Stair Treads The anti-slip nature and open design of welded bar grating make it an ideal choice for stair treads, enhancing safety in environments where liquids and debris are present.

3. Drainage Covers In areas prone to flooding or excessive water accumulation, welded bar grating can effectively cover drainage channels while allowing for water flow, thus preventing accidents and ensuring quick drainage.

4. Product Support In warehouses and manufacturing plants, welded bar grating is employed as a support structure for products and machinery, providing a strong, stable surface that can withstand heavy loads.

5. Safety Barriers The robust construction of welded bar grating allows it to serve as safety barriers in various locations, preventing falls and enhancing workplace safety.

Benefits of Welded Bar Grating

Welded bar grating offers numerous advantages that make it a popular choice in many industries

. Key benefits include1. Strength and Durability The welded construction provides enhanced strength compared to other types of grating, making it suitable for high-load applications. It is resistant to impact, corrosion, and wear, ensuring a long lifespan.

welded bar grating

2. Lightweight yet Strong Despite its robust nature, welded bar grating is surprisingly lightweight, making it easier to handle and install while reducing delivery costs.

3. Design Flexibility Welded bar grating comes in various sizes, spacing, and thickness options, allowing designers and engineers to customize it to fit specific project requirements.

4. Easy Maintenance The open grid design allows for simple cleaning and maintenance, as debris can easily fall through the grating, reducing the need for manual cleaning.

5. Cost-Effectiveness While the initial investment may be higher than alternative materials, the long-term durability and low maintenance costs make welded bar grating a cost-effective solution.

Manufacturing Process

The manufacturing of welded bar grating involves several key steps

1. Material Selection The first step is selecting the appropriate materials—typically steel, stainless steel, or aluminum, depending on the application and environment.

2. Cutting and Shaping The load bars and cross bars are cut to the required lengths and shaped accordingly.

3. Welding Using high-quality welding techniques, the cross bars are welded perpendicular to the load bars at consistent intervals to form the grid pattern.

4. Finishing The grating undergoes finishing processes such as galvanization or powder coating to enhance corrosion resistance and durability.

5. Quality Inspection Before shipping, each piece of welded bar grating is subjected to rigorous quality control checks to ensure it meets industry standards.

Conclusion

Welded bar grating is a valuable asset in various industries, offering strength, safety, and versatility. Its unique design allows for efficient drainage, easy maintenance, and customization, making it suitable for numerous applications. Understanding the manufacturing process further underscores the importance of quality in the final product. For those seeking a reliable and durable solution for walkways, platforms, or industrial support, welded bar grating proves to be an excellent choice. As industries continue to evolve, the demand for innovative materials like welded bar grating will only grow, reinforcing its significance in modern construction and safety practices.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025