- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Rope Mesh Solutions for Enhanced Safety and Performance on Helidecks and Marine Structures

The Importance of Rope Helideck Mesh in Aviation Safety

In the realm of aviation, particularly in offshore operations, safety is of paramount importance. Among the many components that contribute to a secure operation, the rope helideck mesh stands out as a critical safety feature. This article delves into the significance of rope helideck mesh, its applications, and how it enhances the safety of helicopter landings and take-offs on offshore platforms.

What is Rope Helideck Mesh?

Rope helideck mesh is a specialized safety net constructed using high-tensile strength ropes. It is designed to be installed on helidecks—dedicated landing areas for helicopters, often found on ships, offshore oil platforms, and buildings. The mesh acts as a barrier that helps safe helicopter operations by providing additional grip and reducing the risk of slippage during landing and takeoff.

Enhancing Safety in Helicopter Operations

Helicopter operations, especially in offshore environments, pose unique challenges

. Factors such as high winds, unpredictable weather, and the dynamic nature of the sea can simulate adverse conditions for landing helicopters. The rope helideck mesh provides several safety enhancements, including1. Increased Traction The textured surface of the rope mesh significantly increases the friction coefficient compared to a smooth helideck surface. This added traction is crucial for helicopter landing skids, preventing slippage during the touchdown phase, particularly in inclement weather.

2. Load Distribution The mesh design allows for an even distribution of the helicopter's weight. This is important for helidecks to ensure that the structural integrity of the platform is maintained even under the dynamic loads experienced during helicopter operations.

rope helideck mesh

3. Emergency Safety In the event of a hard landing or mishap, the rope helideck mesh can serve as a cushioning layer. Although it is not designed to replace robust safety measures, it can mitigate the impact forces on both the aircraft and the helideck structure.

Material and Design Considerations

Rope helideck meshes are constructed from durable, weather-resistant materials such as high-density polyethylene (HDPE) or polyamide. These materials are chosen for their strength, flexibility, and longevity, making them particularly suitable for harsh offshore conditions. The design of the mesh typically involves a network of knots or weaves that enhance its structural strength while maintaining a lightweight profile.

Installation and Maintenance

Proper installation of rope helideck mesh is crucial for its effectiveness. It must be securely anchored to the helideck surface to withstand the forces exerted during helicopter operations. Additionally, regular maintenance checks are necessary to ensure that the mesh remains free from wear and tear, contamination, and other potential hazards that could compromise safety.

Conclusion

In conclusion, rope helideck mesh plays a vital role in enhancing the safety of helicopter operations on helidecks. By providing increased traction, load distribution, and emergency safety features, it helps mitigate the risks associated with landing and takeoff in challenging environments. As the aviation industry continues to evolve and engage with demanding offshore operations, the importance of robust safety measures, like the rope helideck mesh, cannot be overstated. Ensuring that helidecks are equipped with these safety solutions is an investment in the well-being of pilots, crew, and valuable equipment, contributing to safer skies and efficient operational outcomes.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

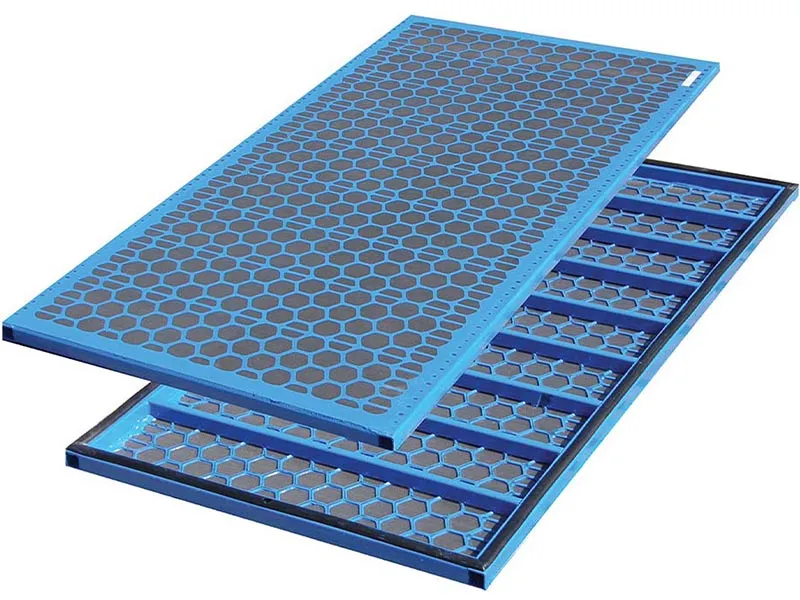

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025