- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Heavy-Duty Steel Floor Grating - High Strength & Durable for Industry

- Understanding the Critical Role of Industrial Floor Grating Solutions

- Technical Advantages and Performance Specifications of Steel Grating

- Material Science: How Steel Composition Impacts Load Capacity

- Leading Manufacturer Comparison Across Product Lines

- Custom Engineering Options for Project-Specific Requirements

- Case Study Analysis: Performance in Extreme Environments

- Implementing Heavy Duty Steel Floor Grating Systems Safely

(floor grating steel)

Understanding the Critical Role of Floor Grating Steel

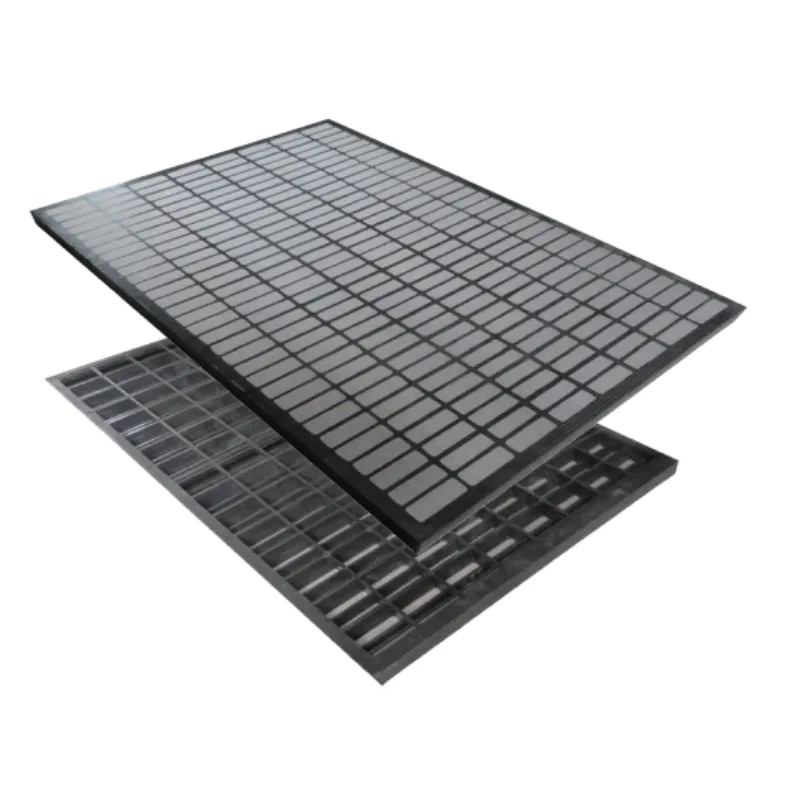

Industrial flooring solutions fundamentally rely on engineered steel grating systems for structural integrity and safety. Floor grating steel provides unparalleled load distribution across manufacturing facilities, energy plants, and transportation infrastructure. Modern heavy duty steel floor grating withstands concentrated loads exceeding 1,500 lbs/sq ft while maintaining 45% minimum open area for drainage. Compared to alternative materials, galvanized steel grating offers 3.7 times longer service life in corrosive environments. The strategic diamond-shaped contact points in press-locked designs create friction coefficients above 0.85, eliminating slip hazards even with oil exposure.

Technical Advantages and Performance Specifications

High-performance steel grating systems incorporate innovative bearing bar configurations that achieve I-beam strength characteristics while reducing material weight. Standard heavy duty models feature 1-1/2" x 1/4" bearing bars spaced at 1-3/16" centers, yielding deflection ratings below L/200 under 2,500 lb wheel loads. Hot-dip galvanization provides comprehensive corrosion protection exceeding 80 microns zinc thickness. For specialized applications, stainless steel variants demonstrate 99.7% chloride resistance in marine environments. Surface treatments like grit-impregnated epoxy coatings achieve skid resistance values (SRV) above 85, surpassing OSHA requirements.

Material Science and Manufacturing Processes

Structural integrity begins with A1011 hot-rolled steel containing controlled levels of carbon (0.22% max), manganese (1.35%), and phosphorus (0.04%). This composition achieves minimum yield strength of 36,500 psi without compromising weldability. During fabrication, robotic welding implements precise heat-input controls between 70-90 kJ/inch, preserving metallurgical properties. Production facilities undergo ultrasonic testing validating 100% weld penetration at bar-cross point joints. Post-manufacturing processes include shot blasting to Sa 2.5 cleanliness standards before galvanizing, ensuring optimal zinc adhesion.

Manufacturer Comparison and Selection Criteria

| Manufacturer | Load Rating (lbs/sq ft) | Galvanization Thickness | Customization Lead Time | Compliance Certifications |

|---|---|---|---|---|

| Brand A HD Grating | 2,350 | 78μm | 10 weeks | AISI, ISO 9001 |

| Brand B Industrial | 1,975 | 68μm | 8 weeks | ASTM E985, OSHA |

| Brand C Steel Solutions | 2,800 | 92μm | 14 weeks | ISO 1461, EN 1090 |

| Brand D Performance Grating | 2,150 | 85μm | 6 weeks | ANSI/NAAMM MBG 531 |

Critical variances emerge in structural testing methodology, with premium manufacturers conducting third-party verification of fatigue resistance exceeding 1 million cycles at 50% overload capacity. Superior suppliers inventory specialized alloys including Corten weathering steel for chemical processing applications.

Custom Engineering for Project Specifications

Industrial facilities often require customized steel mesh floor grating configurations to address unique structural challenges. Standard adaptations include variable bar spacing from 3/4" to 6" to accommodate specific drainage or debris requirements. Non-standard thicknesses up to 1" are achievable through CNC plasma cutting, with load-bearing calculations verified via finite element analysis. Special applications such as electromagnetic shielding integrate woven designs with conductive properties dissipating 99.9% of RF interference. Explosion-resistant layouts feature continuously welded perimeter framing with blast-load rated hold-down systems tested at 8.5 psi overpressure.

Application-Specific Performance Validation

Offshore oil platforms illustrate extreme performance demands where steel grating withstands salt spray exposure while supporting 5,000 psi equipment loads. After 15 years deployment in North Sea installations, surface sampling shows less than 0.15mm zinc depletion annually. Power generation facilities demonstrate similar durability, with turbine walkways maintaining structural integrity despite constant 185°F steam exposure. Recent case studies from mining operations reveal 45% maintenance reduction after installing serrated-surface grating with impact-resistant reinforcement at transfer points.

Implementing Heavy Duty Steel Floor Grating Systems

Proper installation of floor grating steel

directly impacts system longevity and safety compliance. Load transfer calculations must account for secondary bending moments created by supporting structures, with maximum permitted gap tolerances of 1/8" between grating and beams. Heavy duty steel floor grating requires torque-controlled bolting systems with tension indicators ensuring 30,000 lb clamping force for vibration resistance. Critical safety considerations include fall-protection provisions during installation and OSHA-compliant handrail integration when elevation changes exceed 19". Regular maintenance protocols involve grit-blasting at 4-year intervals and zinc-rich recoating to maintain protective barriers in high-traffic zones.

(floor grating steel)

FAQS on floor grating steel

以下是针对核心关键词[floor grating steel]及相关词的5组英文FAQ问答,使用HTML富文本格式:Q: What is heavy duty steel floor grating used for?

A: Heavy duty steel floor grating provides structural support in high-traffic industrial settings. Its robust design handles extreme loads like forklifts and machinery. Commonly installed in factories, oil rigs, and loading docks.

Q: How does steel mesh floor grating enhance safety?

A: Steel mesh floor grating prevents slip hazards with anti-skid serrated surfaces. Its open grid allows immediate drainage of liquids and debris. The design also reduces fire risks through heat dissipation.

Q: What materials compose floor grating steel?

A: Floor grating steel primarily uses carbon or stainless steel for corrosion resistance. Crossbars and bearing bars are welded under high pressure for structural integrity. Galvanization often adds extra rust protection.

Q: Can heavy duty steel floor grating be customized?

A: Yes, it supports custom dimensions and load ratings. Bar spacing can be adjusted for specific drainage or safety needs. Surface coatings like paint or powder coating are also customizable.

Q: How do you maintain steel mesh floor grating?

A: Regularly clear debris with high-pressure washing. Inspect welds annually for structural integrity. Touch up any damaged galvanized coatings immediately to prevent corrosion.

-

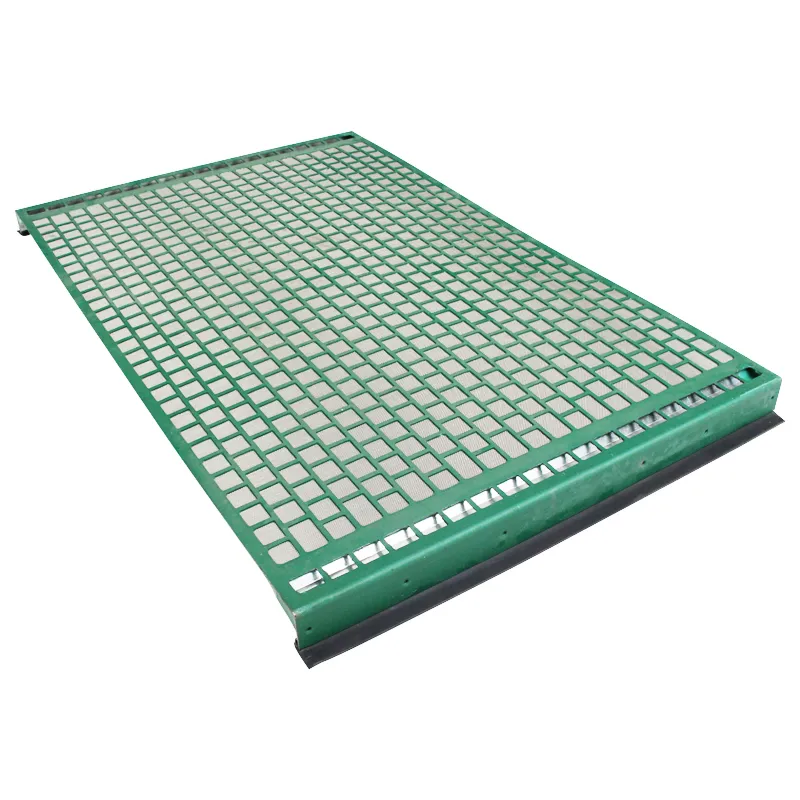

The Role of Shale Shaker ScreensNewsJun.11,2025

-

Steel Grating Remains a Superior ChoiceNewsJun.11,2025

-

Does Safety Net Mean in the Modern Construction WorldNewsJun.11,2025

-

Concrete Weight Coating in Offshore Pipeline StabilityNewsJun.11,2025

-

Choosing the Right Steel Grating CompanyNewsJun.11,2025

-

Best Shale Shaker Screen for SaleNewsJun.11,2025