- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 11, 2025 09:25

Back to list

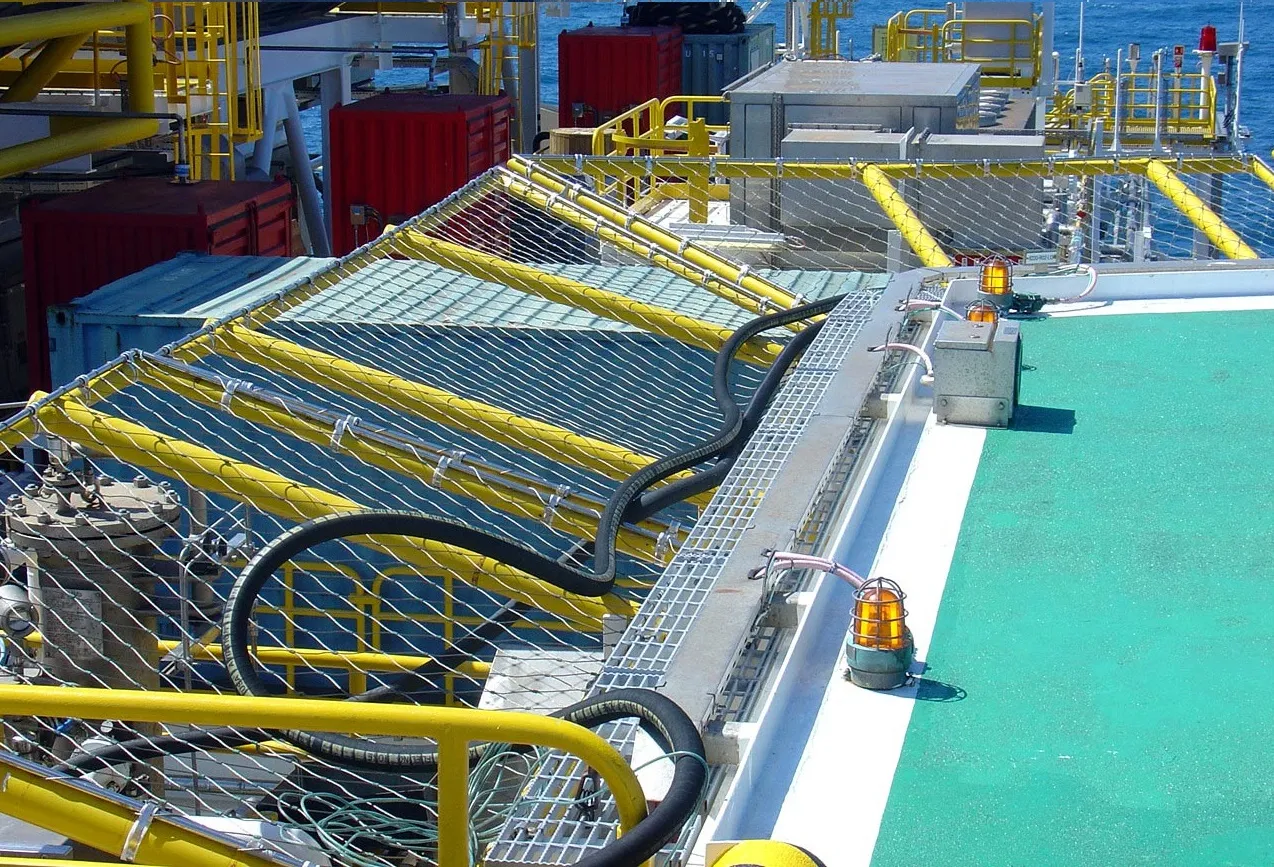

lightweight grating

In recent years, lightweight grating has become a key player in industries that demand a combination of strength, durability, and weight efficiency. This versatile product finds applications in diverse sectors such as architecture, construction, and industrial manufacturing, offering a modern solution to age-old challenges.

Maintenance advantages of lightweight grating also deserve a mention. Their resistance to corrosion and chemical damage means they require less frequent replacement or repair compared to traditional materials. This longevity not only provides cost benefits but also minimizes the environmental impact associated with manufacturing, transporting, and installing new materials. In terms of real-world applications, lightweight grating is invaluable in designing walkways, platforms, sun shades, and drainage covers. Their permeability also makes them an excellent choice for areas that need efficient airflow or light penetration. This range of applications underscores the versatility and importance of lightweight grating across various sectors. From an expertise standpoint, engineers and architects must understand the characteristics and best use cases for different types of lightweight grating. It is essential to assess factors like load-bearing capabilities, environmental conditions, and expected wear and tear to select the most appropriate material. Consulting with professionals knowledgeable in lightweight grating ensures that projects maximize these materials' benefits, combining efficiency with innovation. Authoritativeness in the industry for lightweight grating is often linked to manufacturers' adherence to quality standards. Products must comply with specific safety, strength, and environmental regulations to ensure reliability and performance. Companies recognized for excellence in research, development, and manufacturing processes set industry benchmarks, offering products that consistently satisfy stringent criteria. Conveying trustworthiness in lightweight grating involves transparency in product specifications and performance guarantees. Providing detailed data sheets and test results helps build confidence among clients and end-users, reassuring them about the product's reliability and long-term benefits. Superior customer service and technical support further reinforce trust, fostering relationships that extend beyond singular transactions. In summary, lightweight grating stands as an exemplar of modern engineering and material science, providing unmatched efficiency and safety while aligning with sustainable practices. It continues to transform industries by offering flexible, cost-effective, and environmentally conscious solutions to complex design and construction challenges.

Maintenance advantages of lightweight grating also deserve a mention. Their resistance to corrosion and chemical damage means they require less frequent replacement or repair compared to traditional materials. This longevity not only provides cost benefits but also minimizes the environmental impact associated with manufacturing, transporting, and installing new materials. In terms of real-world applications, lightweight grating is invaluable in designing walkways, platforms, sun shades, and drainage covers. Their permeability also makes them an excellent choice for areas that need efficient airflow or light penetration. This range of applications underscores the versatility and importance of lightweight grating across various sectors. From an expertise standpoint, engineers and architects must understand the characteristics and best use cases for different types of lightweight grating. It is essential to assess factors like load-bearing capabilities, environmental conditions, and expected wear and tear to select the most appropriate material. Consulting with professionals knowledgeable in lightweight grating ensures that projects maximize these materials' benefits, combining efficiency with innovation. Authoritativeness in the industry for lightweight grating is often linked to manufacturers' adherence to quality standards. Products must comply with specific safety, strength, and environmental regulations to ensure reliability and performance. Companies recognized for excellence in research, development, and manufacturing processes set industry benchmarks, offering products that consistently satisfy stringent criteria. Conveying trustworthiness in lightweight grating involves transparency in product specifications and performance guarantees. Providing detailed data sheets and test results helps build confidence among clients and end-users, reassuring them about the product's reliability and long-term benefits. Superior customer service and technical support further reinforce trust, fostering relationships that extend beyond singular transactions. In summary, lightweight grating stands as an exemplar of modern engineering and material science, providing unmatched efficiency and safety while aligning with sustainable practices. It continues to transform industries by offering flexible, cost-effective, and environmentally conscious solutions to complex design and construction challenges.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025