- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Understanding Grating Prices for Your Cooking and Baking Needs

Understanding Grating Prices Factors That Influence Costs and Market Trends

In the world of construction and engineering, grating plays a crucial role. Grating can refer to various forms of platforms, floors, and covers that allow for drainage, ventilation, and safety in industrial settings. The demand for high-quality grating solutions has led to a burgeoning market, with prices varying significantly based on several factors. In this article, we will explore what influences grating prices, including material selection, manufacturing processes, and market trends.

Types of Grating and Their Costs

Gratings come in various types, including steel, fiberglass, aluminum, and plastic. Each material carries its own pricing structure due to differences in material properties, production processes, and durability. Steel grating, for example, is one of the most commonly used types owing to its strength and versatility. The cost of steel is subject to fluctuations based on global demand, tariffs, and mining activities. As of recent trends, rising steel prices have led to increased costs for steel grating, impacting many industries reliant on this material.

Fiberglass grating, on the other hand, has gained popularity, especially in corrosive environments where traditional metals may fail. Although it often costs more initially than steel grating, its long-term benefits—such as low maintenance and resistance to corrosion—make it a cost-effective choice over time. The inherent properties of fiberglass influence its pricing, with variations based on attributes such as load capacity and open area.

Manufacturing Processes

The production process of grating significantly impacts its final price. For instance, welded steel grating usually demands a higher manufacturing cost compared to molded fiberglass due to the labor-intensive welding processes required. Manufacturers that employ advanced technologies and automation may achieve lower production costs, thereby offering more competitive pricing in the market.

Additionally, custom grating solutions—as opposed to standard off-the-shelf options—can lead to increased costs. Customizations often involve engineering and design fees, which can add to the overall price. Furthermore, sourcing raw materials for specialized applications can also contribute to elevated prices.

grating price

Economic Influences and Supply Chain Dynamics

Grating prices are not only affected by manufacturing processes but also by broader economic factors. The rise and fall of commodity prices directly correlate with the costs of raw materials. Economic downturns, trade restrictions, and global market shifts can create supply chain disruptions, resulting in scarcity and increased costs.

The COVID-19 pandemic serves as a recent example of how unforeseen circumstances can impact the industry. Supply chain interruptions, labor shortages, and skyrocketing freight costs led to significant increases in the price of grating materials. These changes revealed the fragility of manufacturing and distribution networks, prompting many companies to reconsider their sourcing strategies.

Market Trends and Future Predictions

As sustainable practices gain traction across many industries, there has been a notable shift towards eco-friendly materials. For grating manufacturers, this shift may lead to new product lines that incorporate recycled materials or innovative composites. While these materials might initially be more expensive, long-term savings and environmental benefits could drive demand and influence pricing structures.

Moreover, technological advancements in manufacturing could lead to more efficient production techniques, ultimately lowering costs. Continuous innovation within the industry may provide opportunities for price stabilization in the future.

Conclusion

The pricing of grating is a multifaceted issue influenced by various factors—from material choices and manufacturing processes to economic dynamics and market trends. Understanding these factors is essential for businesses looking to navigate the complexities of grating procurement effectively. As the market evolves, staying informed about pricing trends and potential shifts in the supply chain will enable companies to make strategic decisions that align with their operational needs and budgetary constraints. Whether using steel, fiberglass, or other alternatives, the key to cost-effective purchasing lies in thorough research and proactive planning.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

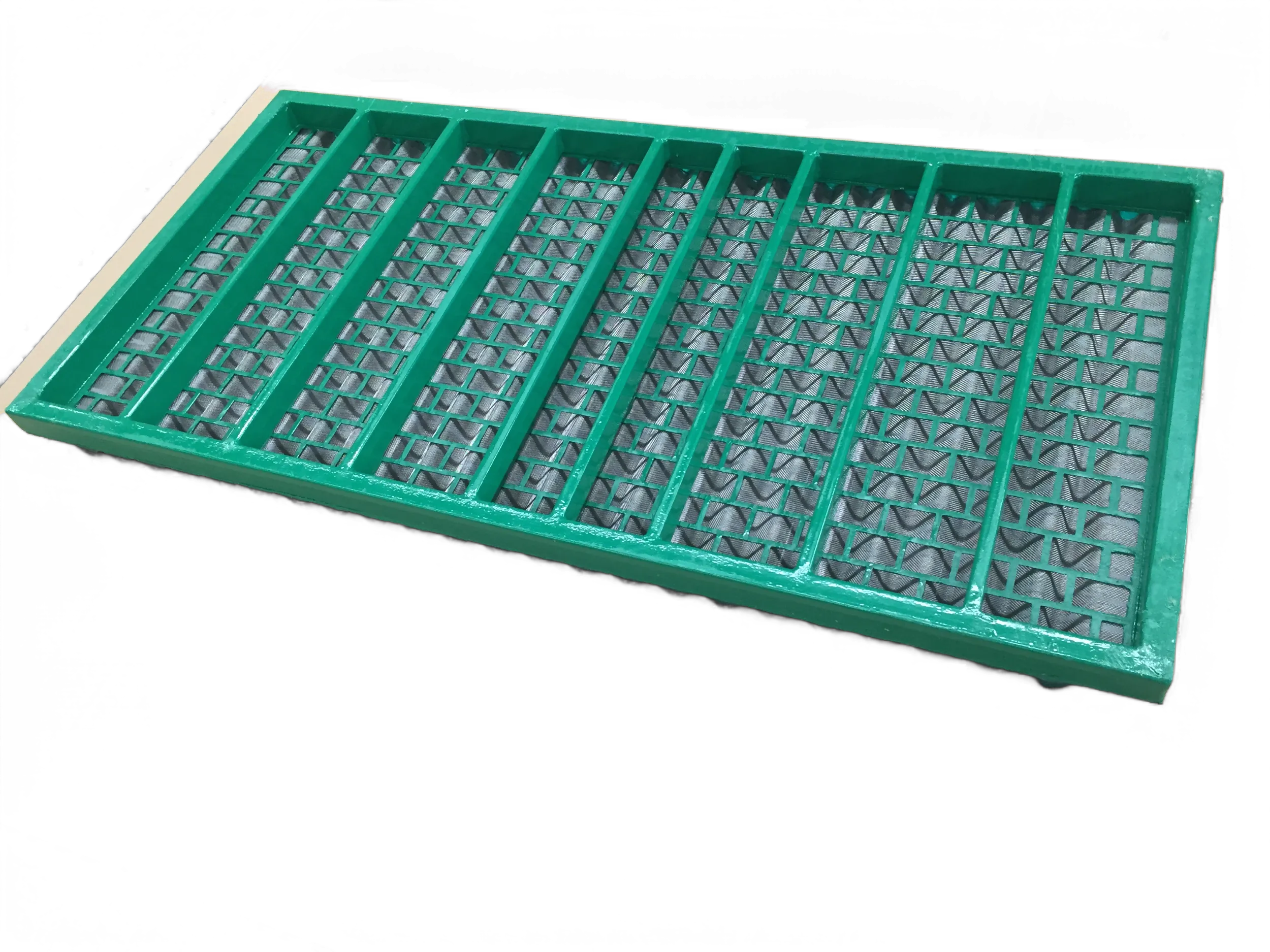

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025