- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 15, 2025 08:46

Back to list

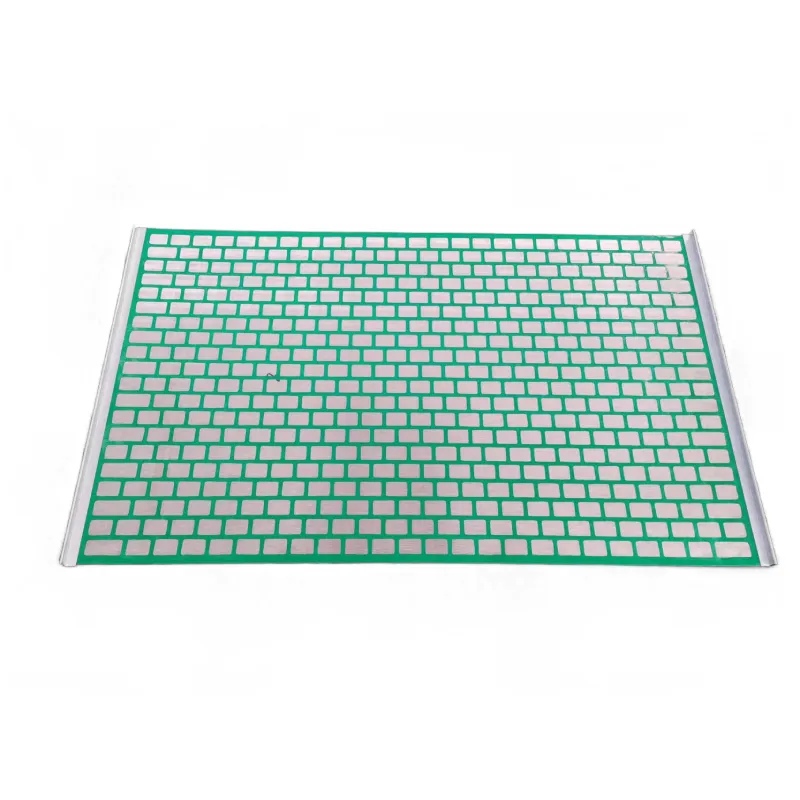

Steel Grating

Galvanised grid mesh flooring stands out as a robust and reliable solution for industries seeking durable flooring options that ensure safety and efficiency. With a track record of enhancing both the structural integrity and functionality of industrial and commercial spaces, this flooring type is an investment that promises long-term benefits.

Beyond its functional attributes, the installation of galvanised grid mesh flooring is relatively straightforward, particularly when executed by professionals versed in this specialization. Its modular nature means that it can be tailored to fit various spatial configurations, accommodating the specific needs of different operational layouts. This adaptability makes it a favored choice among engineers and architects aiming for both function and form in their designs. Moreover, the aesthetic appeal of galvanised grid mesh flooring should not be overlooked. Its industrial aesthetic, with a sleek metallic finish, enhances the visual appeal of contemporary spaces. This element is especially attractive in urban industrial design contexts, where the fusion of functionality and style is increasingly sought after. In terms of environmental impact, galvanised grid mesh flooring is a conscientious choice. Steel, the primary substrate used in this flooring type, is among the most recyclable materials in the world. Its longevity further contributes to sustainability, as its resistance to wear and tear means fewer resources are spent on replacements and repairs over the lifespan of the building. In conclusion, galvanised grid mesh flooring excels across multiple dimensions—durability, safety, aesthetics, sustainability, and cost-effectiveness. Its comprehensive benefits are recognized by industry experts, establishing it as a trusted and authoritative solution in the realm of industrial and commercial flooring. Investing in galvanised grid mesh flooring is not merely a choice for immediate practicality but a strategic decision that aligns with long-term operational excellence and sustainability goals.

Beyond its functional attributes, the installation of galvanised grid mesh flooring is relatively straightforward, particularly when executed by professionals versed in this specialization. Its modular nature means that it can be tailored to fit various spatial configurations, accommodating the specific needs of different operational layouts. This adaptability makes it a favored choice among engineers and architects aiming for both function and form in their designs. Moreover, the aesthetic appeal of galvanised grid mesh flooring should not be overlooked. Its industrial aesthetic, with a sleek metallic finish, enhances the visual appeal of contemporary spaces. This element is especially attractive in urban industrial design contexts, where the fusion of functionality and style is increasingly sought after. In terms of environmental impact, galvanised grid mesh flooring is a conscientious choice. Steel, the primary substrate used in this flooring type, is among the most recyclable materials in the world. Its longevity further contributes to sustainability, as its resistance to wear and tear means fewer resources are spent on replacements and repairs over the lifespan of the building. In conclusion, galvanised grid mesh flooring excels across multiple dimensions—durability, safety, aesthetics, sustainability, and cost-effectiveness. Its comprehensive benefits are recognized by industry experts, establishing it as a trusted and authoritative solution in the realm of industrial and commercial flooring. Investing in galvanised grid mesh flooring is not merely a choice for immediate practicality but a strategic decision that aligns with long-term operational excellence and sustainability goals.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025