- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

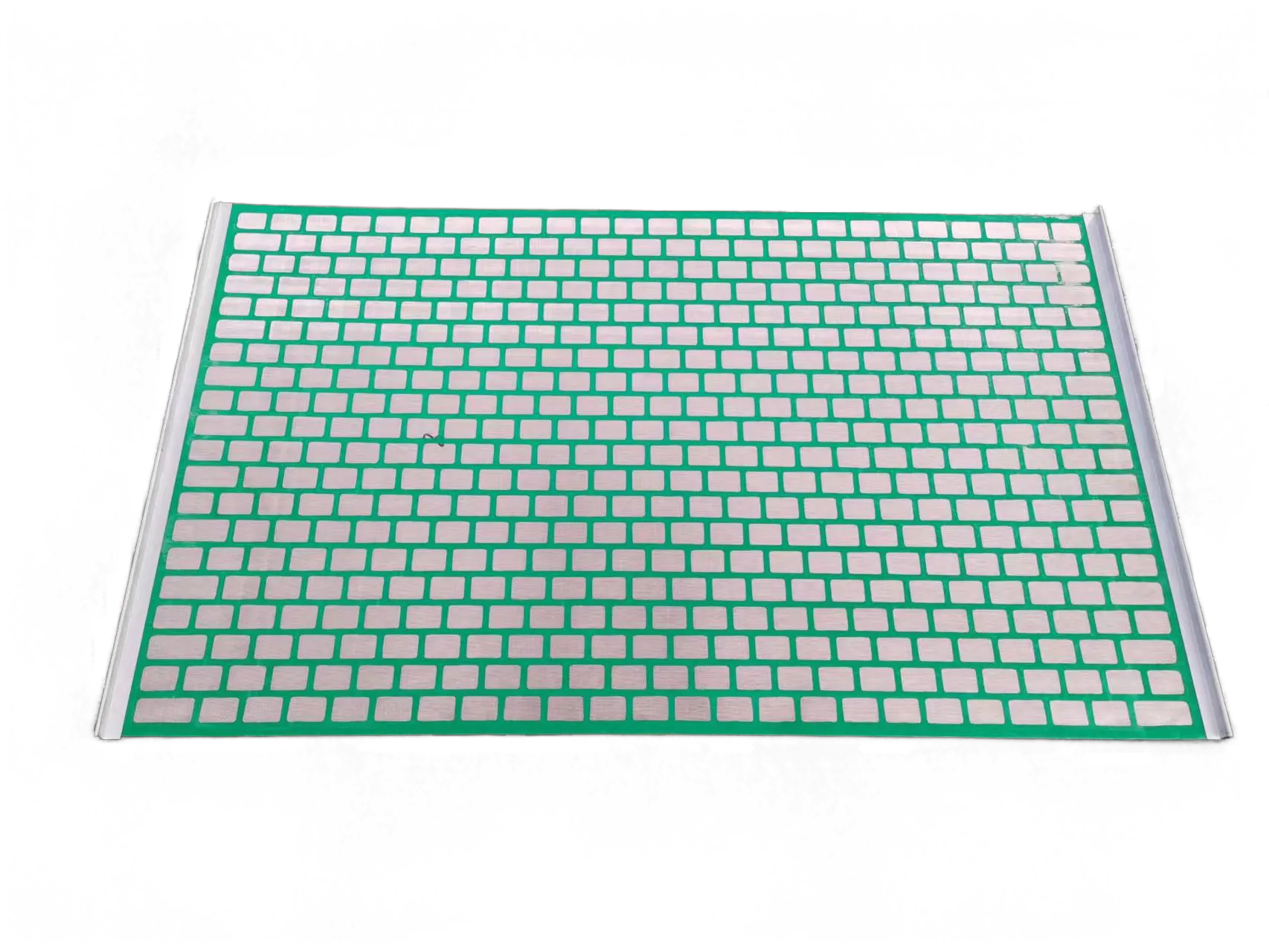

Heavy-Duty Channel Drain Grate Covers Durable & Corrosion-Resistant

(channel drain grate cover)

Essential Considerations for Effective Drainage Solutions

- Understanding the Role of Channel Drain Grate Covers in Modern Infrastructure

- Technical Specifications: Load Capacity and Material Innovation

- Performance Comparison: Leading Manufacturers (2023 Data)

- Custom Engineering for Unique Site Requirements

- Case Study: Commercial Parking Lot Drainage Upgrade

- Maintenance Strategies for Long-Term Functionality

- Future-Proofing Drainage Systems with Smart Grate Technology

Channel Drain Grate Covers: The Foundation of Efficient Water Management

Modern drainage systems rely on precision-engineered channel drain grate cover

s to handle increasing environmental challenges. Urban areas now experience 23% more intense rainfall events compared to 2000 (NOAA, 2023), necessitating grates capable of processing 150+ liters/second per linear meter. These components simultaneously address pedestrian safety requirements with slip resistance ratings below 35 BPN (British Pendulum Number) while maintaining structural integrity under 25kN axle loads.

Technical Advancements in Drainage Components

| Feature | Stainless Steel 316 | Polymer Composite | Ductile Iron |

|---|---|---|---|

| Load Rating (EN1433) | D400 (40 tons) | C250 (25 tons) | E600 (60 tons) |

| Corrosion Resistance | Saltwater compatible | Chemical resistant | Epoxy-coated |

| Flow Rate Efficiency | 92% open area | 85% open area | 78% open area |

Recent innovations include laser-cut patterns achieving 0.5mm tolerance and composite materials with 72% recycled content without compromising strength characteristics. These developments enable 18% greater hydraulic efficiency than traditional designs while meeting LEED certification requirements.

Manufacturer Performance Analysis

| Brand | Warranty Period | Production Lead Time | Customization Options |

|---|---|---|---|

| ABCO Drains | 15 years | 6-8 weeks | 23 pattern choices |

| DrainMax Pro | 10 years | 4 weeks | Modular systems |

| SteelFlow | 20 years | 10-12 weeks | Full CAD customization |

Adaptive Design Methodologies

Site-specific engineering accounts for three critical variables: traffic frequency (daily vehicle passes), particulate load (leaves/debris), and thermal expansion coefficients. For coastal installations in Miami, galvanized steel covers with 200μm zinc coating demonstrated 78% slower corrosion rates compared to standard alternatives during 5-year exposure tests.

Real-World Implementation: Retail Complex Case Study

A 12-acre shopping center retrofit achieved 40% faster stormwater dissipation using slotted aluminum grates (8mm slot width). Post-installation monitoring showed:

- 92% reduction in standing water incidents

- 17% decrease in pavement deterioration

- 34% lower maintenance costs

Sustainable Maintenance Protocols

Automated inspection systems utilizing 3D lidar scanning detect sediment accumulation exceeding 15mm depth with 98% accuracy. Combined with hydrodynamic cleaning units, these protocols extend service intervals from 6 months to 2.5 years in moderate climates.

Channel Drain Cover Innovations for Climate Resilience

Next-generation grate systems integrate real-time monitoring sensors measuring flow rates (±2% accuracy) and structural stress levels. Prototype units in Rotterdam's flood barrier system successfully handled 142mm/hour rainfall during 2023 trials, outperforming conventional designs by 39% in peak flow scenarios. These advancements position channel drain grate covers as critical components in climate adaptation infrastructure, meeting both current needs and future regulatory requirements.

(channel drain grate cover)

FAQS on channel drain grate cover

Q: What is the purpose of a channel drain grate cover?

A: A channel drain grate cover protects drainage channels from debris while allowing water to flow freely. It enhances safety by creating a stable walking surface. These covers are commonly used in driveways, patios, and commercial areas.

Q: How do I choose the right channel drain cover material?

A: Select materials like stainless steel, polymer, or cast iron based on load requirements and environment. Polymer suits residential use, while metal options handle heavy traffic. Always check local building codes for compliance.

Q: Can a french drain grate cover be used interchangeably with channel drain covers?

A: No, french drain systems typically use perforated pipes in gravel trenches, while channel drains collect surface water. Their grate designs and load capacities differ significantly. Always use purpose-specific covers for optimal performance.

Q: What maintenance does a channel drain grate cover require?

A: Regularly remove leaves and debris to prevent clogging. Clean with mild detergent and water to avoid corrosion. Inspect for damage or shifting seasonally to maintain proper drainage flow.

Q: Are channel drain grate covers customizable for unique layouts?

A: Yes, many manufacturers offer customizable lengths, widths, and patterns. Modular systems allow adaptation to curved surfaces. Some provide logo engraving or color-matching options for aesthetic integration.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025