- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

bar grating span

Understanding Bar Grating Span An Overview

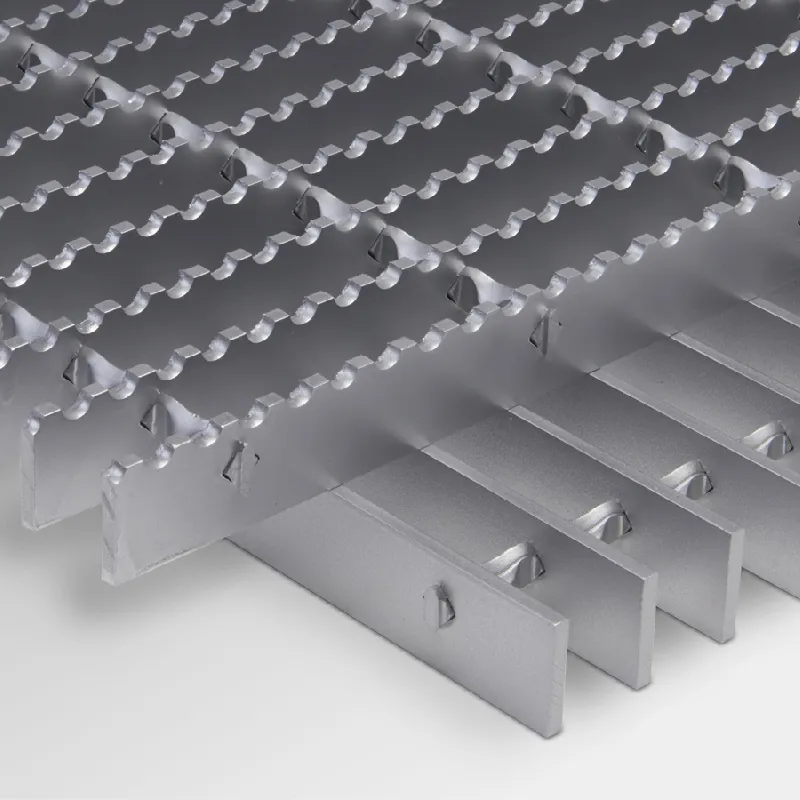

Bar grating spans are an essential aspect of various architectural and engineering applications, serving both functional and aesthetic purposes. These structures, often composed of metal or fiberglass, are characterized by a series of parallel bars that create a grid pattern. Bar gratings are versatile and can be used in numerous settings, from industrial facilities to pedestrian walkways.

Definition and Composition

Bar grating is primarily defined by its construction, usually made from steel, stainless steel, aluminum, or plastic composites. The design consists of load-bearing bars spaced at regular intervals, with crossbars that help maintain structural integrity. The spacing between these bars can vary depending on the intended application—ranging from narrow openings that prevent objects from falling through to wider gaps that allow for drainage or ventilation.

Importance of Span in Bar Grating

The span of bar grating refers to the distance between the supports that hold the grating in place. This span is critical because it directly impacts the structure's strength and safety. A longer span may require thicker bars or closer spacing to ensure that the grating can bear anticipated loads without bending or breaking. Additionally, factors such as material properties, load requirements, and environmental conditions must be considered during the design phase.

Applications and Uses

bar grating span

Bar grating is utilized in a multitude of applications. In industrial settings, it commonly serves as flooring for catwalks, platforms, and stairways. Its open design allows for easy drainage and ventilation, making it ideal for areas that experience liquid spills or require air circulation. In commercial spaces, bar grating can be used for decorative purposes, adding an industrial aesthetic to a building while providing functional surfaces for walkways, ramps, or decorative features.

Another critical application of bar grating spans is in the construction of safety barriers and guardrails. The strength and lightweight nature of bar gratings make them a preferred choice for providing safety in elevated areas. In addition, the open design minimizes wind resistance, which is advantageous in outdoor environments.

Design Considerations

When designing bar grating spans, several factors must be taken into account. Load capacity is one of the most crucial considerations; engineers must ensure that the chosen grating can support the expected weight, including both static loads (such as people or equipment) and dynamic loads (such as moving vehicles). The span must also comply with relevant building codes and regulations to ensure safety and durability.

Environmental factors such as corrosion resistance should be considered. For example, gratings used in coastal areas may require materials that withstand saltwater exposure. Similarly, gratings in chemical plants might need coatings to resist aggressive substances.

Conclusion

In summary, the concept of bar grating span extends beyond mere measurement; it embodies a combination of engineering principles, safety considerations, and practical applications. Understanding the dynamics of span, from material selection to load capacities, is essential for professionals tasked with designing and implementing these structures. As industries evolve and new materials are developed, the applications and technologies surrounding bar grating continue to broaden, highlighting its importance in modern construction and engineering. As we look to the future, the versatility of bar grating will ensure its continued relevance in creating safe, durable, and functional spaces across various industries.

-

Welded Steel Bar Grating: The Strongest Choice for Industrial FlooringNewsMay.21,2025

-

Steel Grating for Sale: The Ultimate Anti-Slip SolutionNewsMay.21,2025

-

Steel Frame Shaker Screens: Unmatched Durability for Demanding OperationsNewsMay.21,2025

-

Shaker Screens: Your Ultimate Solution for Oil & Gas FiltrationNewsMay.21,2025

-

Press Locked Steel Grating: The Smarter Choice for Heavy-Duty FlooringNewsMay.21,2025

-

Helicopter Deck Safety Nets: Protect Your Crew and EquipmentNewsMay.21,2025