- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

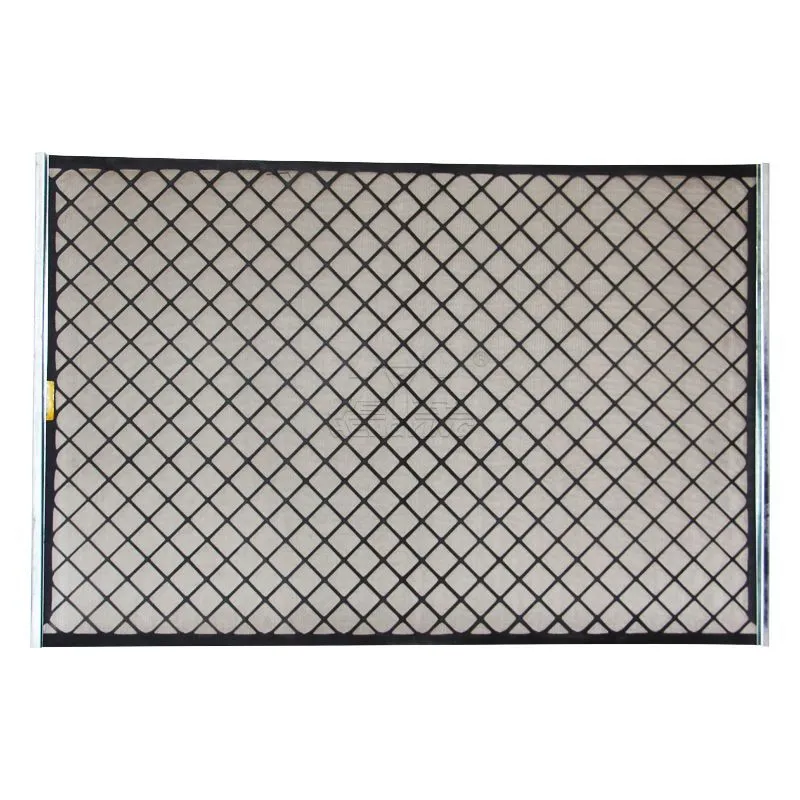

Durable and Lightweight Aluminum Grating for Various Industrial Applications

The Versatile Applications of Aluminum Grating

Aluminum grating has emerged as a popular choice across industries due to its unique properties and versatile applications. A lightweight yet robust material, aluminum grating combines strength, durability, and resistance to corrosion, making it an ideal solution for various demanding environments. This article will explore the diverse uses of aluminum grating, its benefits, and why it is becoming a go-to option in modern construction and industrial design.

The Composition of Aluminum Grating

Aluminum grating is typically made from high-grade aluminum alloy, which provides an excellent strength-to-weight ratio. The grating is often fabricated using extrusion or welding processes, creating a series of parallel bars in various patterns that enhance both functionality and aesthetics. The surfaces of aluminum grating can be treated with protective coatings to increase their resistance to wear and corrosion, making them suitable for exposure to harsh chemicals, moisture, and extreme temperatures.

Benefits of Aluminum Grating

1. Lightweight and Easy to Handle One of the most significant advantages of aluminum grating is its lightweight nature. This characteristic simplifies transportation and installation, reducing labor costs and time. It can be easily cut and shaped to fit specific applications, contributing to its widespread use in various industries.

2. Corrosion Resistance Aluminum's natural oxide layer provides exceptional resistance to corrosion. Unlike steel, which can rust when exposed to moisture, aluminum grating remains intact, preserving its structural integrity and aesthetic appeal. This makes it an excellent choice for outdoor applications and environments where exposure to chemicals is a concern.

3. Durability Aluminum grating is not only lightweight but also highly durable. It can withstand heavy loads and impacts without deforming, which is essential for applications in industrial settings or public infrastructure. With a lifespan that often surpasses steel in many environments, aluminum grating offers long-term value.

4. Safety Features Many designs of aluminum grating include features such as slip-resistant surfaces, which enhance safety in environments that may become wet or oily. This is particularly important in facilities such as manufacturing plants, food processing units, and commercial kitchens.

aluminum grating

5. Aesthetic Appeal Beyond its functionality, aluminum grating can be finished in various designs and powder-coated in different colors, making it suitable for architectural applications where aesthetics matter. This flexibility allows it to fit seamlessly into modern design concepts while still providing essential support and safety.

Applications of Aluminum Grating

1. Industrial Use Aluminum grating is extensively used in factories, warehouses, and manufacturing facilities for walkways, platforms, and stairways. Its ability to support weight while remaining lightweight makes it ideal for areas with heavy foot traffic or machinery.

2. Outdoor Installations The corrosion-resistant properties of aluminum grating make it a preferred choice for outdoor applications, such as bridges, parks, and boardwalks. It can also be used for drainage covers and grates in landscaping projects, providing both function and form.

3. Commercial Facilities Retail spaces, airports, and office buildings benefit from aluminum grating in the form of decorative walkways and protective air vents. Its modern look can enhance the visual appeal of commercial establishments while ensuring safety and accessibility.

4. Wastewater Treatment Plants Due to its resistance to chemicals and moisture, aluminum grating is commonly used in wastewater treatment facilities. It can withstand the harsh conditions often found in these environments, maintaining reliability and performance.

5. Transportation In transportation infrastructure, aluminum grating is often utilized for bus and train stations, providing durable and safe walking surfaces. It can also be found in airports for walkways and as part of luggage handling systems, where both weight and strength are crucial.

Conclusion

Aluminum grating represents a significant advancement in materials used for construction and industrial applications. With its lightweight yet durable nature, corrosion resistance, and aesthetic flexibility, aluminum grating is becoming increasingly favored in various sectors. Whether for a large-scale industrial facility or an elegant architectural project, aluminum grating provides a reliable, safe, and appealing solution that continues to meet the evolving needs of modern design. As industries push toward more sustainable and efficient materials, aluminum grating will undoubtedly remain a central element in future developments.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025