- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

serrated grating weight

Understanding Serrated Grating Weight A Comprehensive Overview

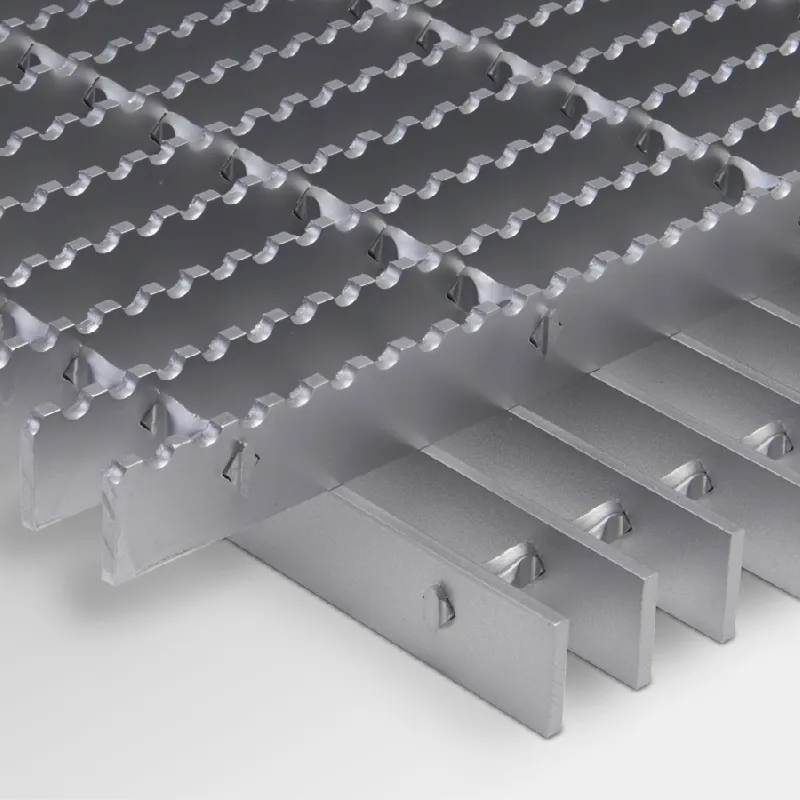

Serrated grating is a specialized type of grating that offers unique advantages in various industrial and architectural applications. Its design, characterized by a series of notches or serrations, lends itself to enhanced safety, improved load distribution, and reduced weight. This article delves into the significance of serrated grating weight, exploring its implications for performance, installation, and overall utility.

1. Definition and Design of Serrated Grating

Serrated grating, often made from materials like steel, aluminum, or fiberglass, features a series of serrations along its surface. These serrations improve traction and prevent slipping, which is particularly important in environments where safety is paramount, such as industrial plants, walkways, and platforms. The design allows for effective drainage while maintaining a secure foothold for personnel or equipment.

2. Weight Considerations

The weight of serrated grating is a critical factor in both selection and installation. The materials used in manufacturing serrated grating can significantly influence its overall weight. For instance, while steel grating is known for its strength and durability, it is also heavier compared to aluminum or fiberglass alternatives.

When weight is a concern—such as in high-rise construction, where reducing load on structural elements is crucial—selecting a lighter option can carry significant advantages. Aluminum serrated grating, while slightly less robust than steel, offers a substantial weight reduction without compromising on safety, making it a popular choice in many applications.

The weight of serrated grating also correlates with its load-bearing capabilities. Gratings are designed to support varying loads depending on their application. The serrated design further contributes to efficient load distribution across its surface area. This means that while the weight of the grating may be a consideration, its ability to handle specific loads must align with industry standards and safety regulations.

serrated grating weight

In selecting serrated grating for particular applications, it is essential to assess the load requirements. For instance, in a manufacturing facility where heavy machinery may be present, thicker and heavier grating might be necessary. Conversely, for pedestrian walkways, lighter grates that still provide adequate load-bearing capabilities would be suitable.

4. Installation Efficiency

Another aspect of serrated grating weight is its impact on installation efficiency. Lighter grating materials can significantly reduce the labor required for transport, handling, and installation. This is particularly beneficial in remote locations or where access is challenging. Moreover, reducing weight can lead to lower transportation costs and less energy expenditure during installation.

The ease of handling lighter materials allows for quicker installations, minimizing downtime in operations. In industries where time is money, choosing the right type of serrated grating can result in substantial savings and improved project timelines.

5. Cost Implications

When considering serrated grating weight, cost implications cannot be overlooked. While lighter options may appear more cost-effective due to lower material costs and easier handling, it is crucial to factor in longevity and maintenance. Comparatively, heavier grating may offer enhanced durability, resulting in lower replacement rates and reduced maintenance costs over time.

Investing in high-quality serrated grating that aligns with project requirements can yield significant returns in terms of performance and cost efficiency. Making informed choices based on weight, material, and application can lead to optimal results.

Conclusion

In summary, the weight of serrated grating plays a vital role in various aspects, from safety and load-bearing capabilities to installation efficiency and cost implications. Understanding these factors can guide designers, engineers, and contractors in selecting the right grating type for specific applications, ensuring both safety and functionality are prioritized. As industries continue to evolve, so too will the innovations in grating materials and designs, making it essential to stay informed on the latest developments in serrated grating technology.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025