- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

grating stainless

Grating Stainless Steel A Comprehensive Overview

Stainless steel grating is an essential material widely utilized across various industries due to its remarkable strength, durability, and resistance to corrosion. This article delves into the fundamental aspects of stainless steel grating, highlighting its types, applications, benefits, and maintenance.

What is Stainless Steel Grating?

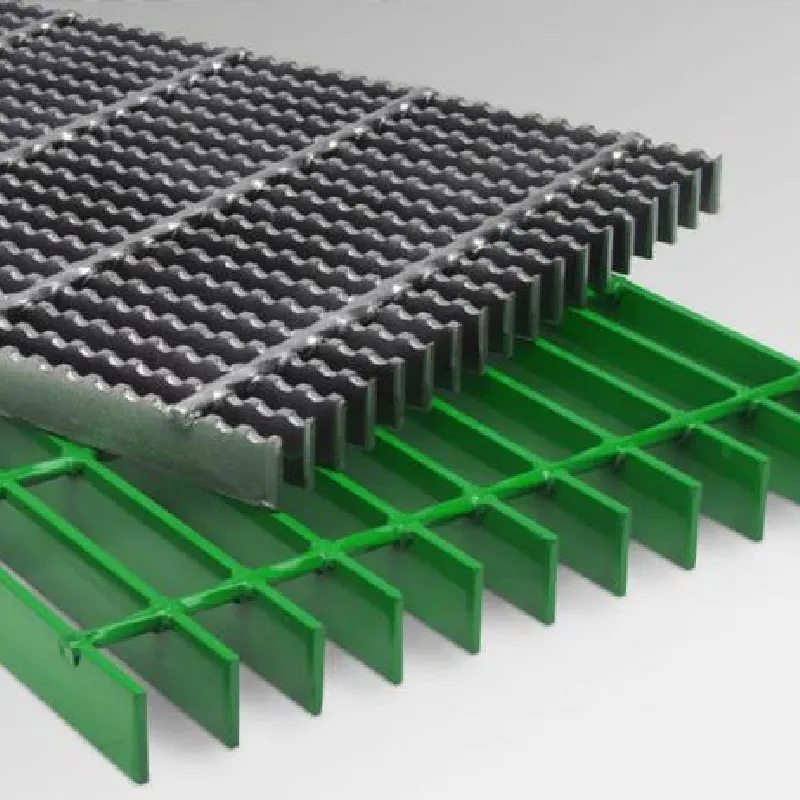

Stainless steel grating is a type of flooring or covering made from stainless steel bars that are welded or molded in a grid-like pattern. This design provides a robust surface that allows for the passage of light, air, water, and debris while ensuring adequate safety for pedestrians and equipment. Available in different configurations and styles, stainless steel grating can be tailored to meet specific needs, making it a versatile choice for many applications.

Types of Stainless Steel Grating

There are several types of stainless steel grating, each suited for particular applications

1. Bar Grating This is the most common type, characterized by parallel bars welded perpendicular to bearer bars. It offers easy installation and high strength for heavy loads. 2. Drainage Grating Specially designed to fit over drainage systems, this type ensures efficient water drainage without compromising safety.

3. Expanded Metal Grating Made from a single sheet of stainless steel, which is slitted and stretched to create a mesh-like structure, offering superior strength and airflow.

Applications of Stainless Steel Grating

grating stainless

Stainless steel grating finds application in diverse sectors, including

- Industrial Facilities Given its load-bearing capacity, stainless steel grating is often used in factories, warehouses, and loading docks for safe walkways and platforms. - Food and Beverage Industries Its corrosion resistance and ease of cleaning make stainless steel grating ideal for food processing facilities where hygiene is crucial. - Marine Environments In coastal areas or industries dealing with water, such as shipbuilding or fishing, stainless steel grating withstands the salty air and high humidity that can cause other materials to corrode. - Commercial Buildings From rooftop walkways to parking garages, stainless steel grating provides both aesthetic appeal and functional safety in urban construction.

Benefits of Using Stainless Steel Grating

Stainless steel grating offers numerous advantages, including

- Durability Stainless steel is known for its strength and long-lasting nature, making it a cost-effective investment over time. - Corrosion Resistance Unlike many other materials, stainless steel doesn't rust, making it an ideal choice for environments that expose it to moisture or chemicals. - Safety Features The open design of stainless steel grating ensures good visibility and light penetration, reducing the risk of accidents by allowing personnel to see any hazards on the ground. - Low Maintenance Stainless steel grating requires minimal upkeep, as its properties prevent issues like rust, and it is easy to clean, making it suitable for high-traffic areas.

Maintenance and Care

While stainless steel grating is low-maintenance, it is still essential to perform regular inspections to ensure its continued safety and functionality. Cleaning should typically involve a simple wash with water and mild detergent to remove any accumulated dirt and grime. For environments with heavy grease, such as kitchens, a degreasing agent may be necessary. Depending on the environment, periodic checks for structural integrity might also be advisable, addressing any signs of wear or damage promptly to prevent safety hazards.

Conclusion

In summary, stainless steel grating is a highly valuable material that combines strength, safety, and longevity. With its broad range of applications and minimal maintenance requirements, it stands out as an exceptional choice for various industries, from manufacturing to commercial construction. As industries continue to evolve, the demand for reliable and efficient materials like stainless steel grating will likely remain high, reinforcing its role as an essential component of modern infrastructure.

-

Upgrade Your Industrial Operations with Durable Steel GratingNewsJul.21,2025

-

Transform Your Flooring Solutions with Quality Floor GratingNewsJul.21,2025

-

Top-Quality Shale Shaker Screens for Your Drilling NeedsNewsJul.21,2025

-

High-Quality Steel Grating for All Your Industrial NeedsNewsJul.21,2025

-

Explore the Durability and Versatility of Galvanized Steel GratingNewsJul.21,2025

-

Ensure Maximum Safety with Premium Safety NetsNewsJul.21,2025