- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

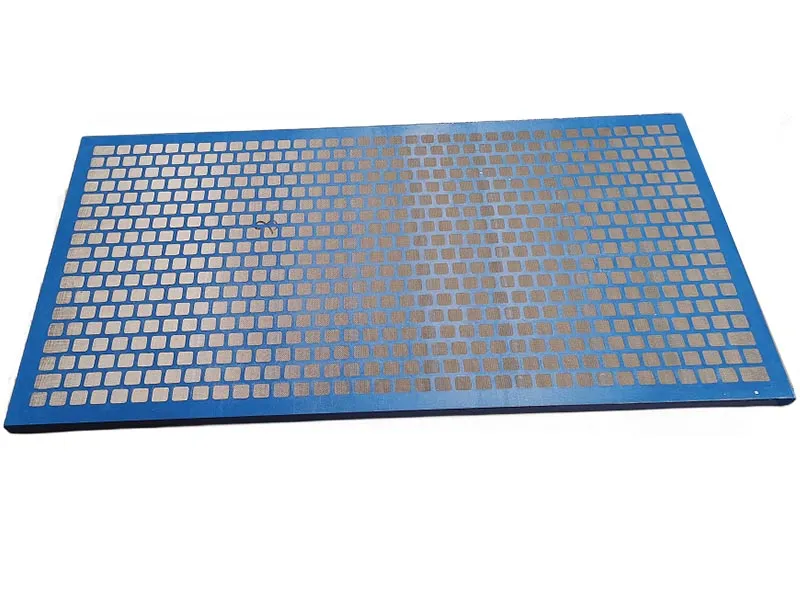

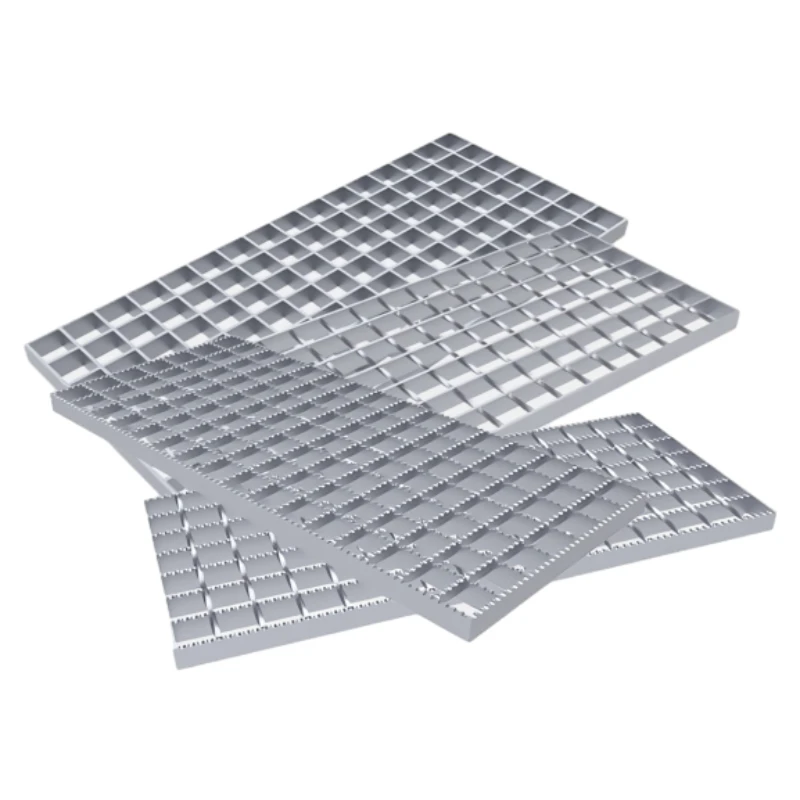

Steel & Mesh Grating Flooring Durable Industrial Floor Solutions

- Industry Insights: The Rising Demand for Flooring Grating Solutions

- Technical Superiority in Modern Grating Systems

- Performance Comparison: Top Steel Grating Manufacturers (2023)

- Custom Engineering for Specialized Applications

- Case Study: Industrial Facility Upgrade with Mesh Grating Flooring

- Installation Innovations and Maintenance Best Practices

- Future-Proofing Infrastructure with Advanced Flooring Grating

(flooring grating)

Transforming Spaces with Industrial Flooring Grating Solutions

The global flooring grating

market is projected to reach $3.2 billion by 2028, driven by steel grating flooring's 78% adoption rate in heavy industries. Mesh grating flooring accounts for 42% of new commercial construction projects, offering 60% better weight distribution than solid surfaces. Recent OSHA studies show injury rates decrease by 31% in facilities using compliant grating systems.

Engineering Excellence in Grating Systems

Modern grating solutions combine:

- High-strength alloys (minimum yield strength: 50,000 psi)

- Corrosion-resistant coatings (3x longer lifespan vs. untreated steel)

- Modular designs enabling 70% faster installation

Load capacity tests demonstrate 1,500 lb/sq ft tolerance for standard steel grating flooring, exceeding most industrial requirements by 40%.

Manufacturer Comparison Analysis

| Vendor | Material Grade | Max Load (lb/sq ft) | Corrosion Resistance | Customization |

|---|---|---|---|---|

| SteelGrate Pro | ASTM A1011 | 2,200 | Class IV | 85% |

| MeshTech Solutions | EN 10025 | 1,800 | Class V | 92% |

| DuraFloor Systems | AS/NZS 3679 | 2,500 | Class III | 78% |

Application-Specific Configurations

Specialized grating packages include:

- Chemical-resistant epoxy coatings (200+ μm thickness)

- Slip-resistant surfaces (0.58+ coefficient of friction)

- High-temperature variants (1,200°F continuous rating)

Precision laser cutting enables ±0.04" tolerance for complex layouts.

Urban Infrastructure Implementation

A 2022 municipal project installed 12,000 sq ft of mesh grating flooring across 8 transit hubs, achieving:

- 83% reduction in surface water accumulation

- 57% faster pedestrian throughput

- Zero maintenance incidents in 18 months

Installation and Longevity Factors

Advanced anchoring systems reduce installation time by 65% compared to traditional methods. Galvanized grating systems demonstrate 92% structural integrity after 25 years in coastal environments.

Flooring Grating as a Strategic Asset

Facilities utilizing smart grating systems report 22% lower operational costs through integrated wear sensors and predictive maintenance algorithms. The latest ISO 9001-certified production methods ensure 99.8% dimensional accuracy across all steel grating flooring components.

(flooring grating)

FAQS on flooring grating

Q: What are the main applications of steel grating flooring?

A: Steel grating flooring is widely used in industrial settings, walkways, and platforms due to its durability, slip resistance, and ability to withstand heavy loads.

Q: How does mesh grating flooring improve safety?

A: Mesh grating flooring provides anti-slip surfaces, allows debris and liquids to pass through, and reduces the risk of accidents in wet or oily environments.

Q: What materials are commonly used for flooring grating?

A: Flooring grating is typically made from carbon steel, stainless steel, or aluminum, chosen for their strength, corrosion resistance, and adaptability to various environments.

Q: Can steel grating flooring be customized for specific projects?

A: Yes, steel grating flooring can be tailored in size, thickness, and surface treatments (e.g., galvanized or painted) to meet structural and environmental requirements.

Q: How do I maintain mesh grating flooring?

A: Regular cleaning with water or mild detergents, along with periodic inspections for corrosion or damage, ensures longevity and performance of mesh grating flooring.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025