- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Design and Safety Considerations for Rope Mesh Systems on Helidecks in Maritime Operations

The Importance of Rope Helideck Mesh in Helicopter Operations

In the evolving landscape of aviation, particularly in offshore operations, safety remains a paramount concern. One of the innovations that have significantly enhanced safety measures is the use of rope helideck mesh. This specialized mesh technology is employed primarily on helidecks, which are landing platforms for helicopters, often found on offshore vessels, oil rigs, and other maritime installations.

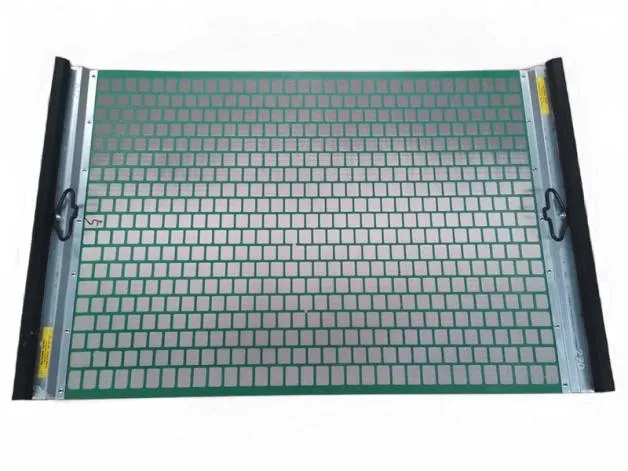

What is Rope Helideck Mesh?

Rope helideck mesh is a robust safety net constructed from high-strength synthetic fibers interwoven to form a grid-like structure. This mesh is designed to provide an added layer of safety for helicopter landings and take-offs, particularly in challenging environments. The primary purpose of the mesh is to prevent helicopter wheels from slipping and to minimize the risk of accidents due to sudden movements or adverse weather conditions.

The design of the rope helideck mesh takes into consideration various factors including load-bearing capacity, environmental resilience, and operational efficiency

. The materials used in the mesh are typically resistant to corrosion, UV degradation, and extreme temperatures, making it an ideal solution for the marine environment.Enhancing Safety in Helicopter Operations

Helicopter operations, especially in offshore locations, come with unique challenges. The combination of strong winds, changing weather conditions, and the dynamic nature of maritime environments can lead to potential hazards during landings. Rope helideck mesh acts as a crucial safety feature by providing additional traction, thus reducing the likelihood of skidding or uncontrolled movements upon landing.

rope helideck mesh

Moreover, this mesh system can also help manage unexpected events, such as equipment failures or emergency landings, by ensuring that helicopters have a stable and secure platform to land on. The presence of the mesh not only enhances the safety of the aircraft but also protects personnel working on the helideck.

Installation and Maintenance

The installation of rope helideck mesh is a specialized process that requires careful planning and execution. The mesh must be properly tensioned to handle the dynamic loads experienced during helicopter operations. Additionally, regular inspections and maintenance are vital to ensure the integrity of the mesh system over time. This includes checking for wear and tear, ensuring that the fastening systems remain secure, and cleaning the mesh to prevent the accumulation of debris that could impact its functionality.

Marine environments can be harsh, with factors such as saltwater exposure and the potential for extreme weather affecting the durability of the mesh. Therefore, operators must adhere to stringent safety standards and protocols to ensure that the helideck remains a safe operational area.

Conclusion

In conclusion, the incorporation of rope helideck mesh has revolutionized helicopter operations, particularly in offshore settings. By providing enhanced safety measures, this innovative mesh technology not only protects the aircraft but also ensures the safety of ground personnel. As offshore operations continue to expand, the importance of advanced safety mechanisms like rope helideck mesh will only increase, reinforcing the industry's commitment to maintaining the highest standards of safety in aviation. The future of helicopter operations will undoubtedly benefit from ongoing advancements in materials and technology, ultimately leading to safer skies and maritime environments.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025