- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

bar grating cost

Understanding the Cost of Bar Grating Factors and Considerations

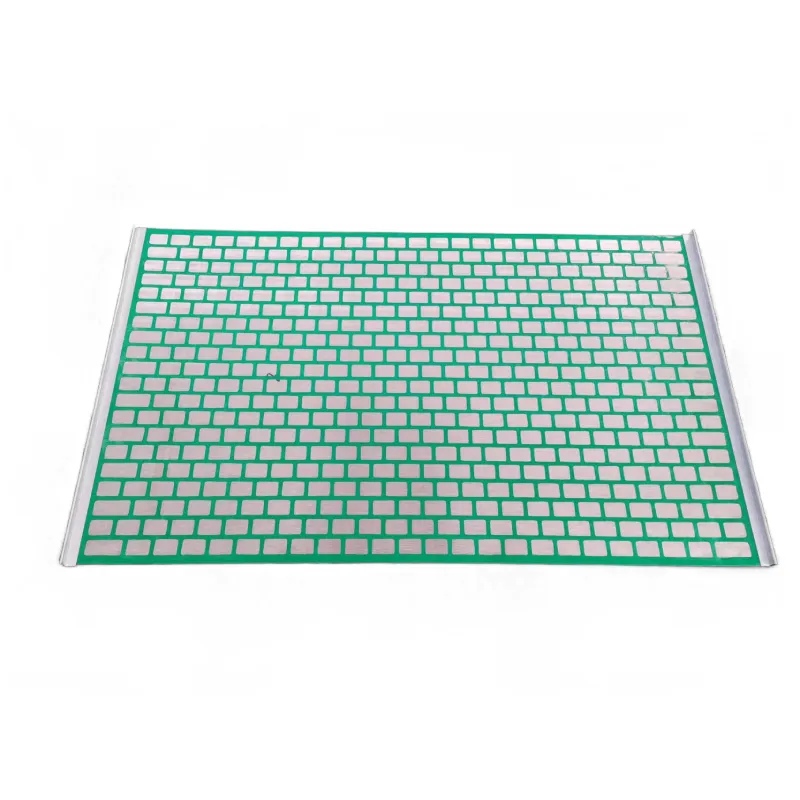

When it comes to industrial applications, bar grating is a vital component utilized in various structures such as floors, walkways, and platforms. Its versatility, strength, and longevity make it an ideal choice for many projects. However, one of the critical aspects that engineers and project managers must consider is the cost associated with bar grating. Understanding what factors influence these costs can facilitate better budgeting and project planning.

What is Bar Grating?

Before delving into costs, it is essential to understand what bar grating is. Bar grating is typically made of metal or fiberglass and comes in several configurations including welded, pressure-locked, and swage-locked types. These grates provide support while allowing light, airflow, and drainage. They are commonly found in industries such as construction, manufacturing, and agriculture.

Factors Influencing the Cost of Bar Grating

1. Material Type The choice of material significantly impacts cost. Standard options include steel, aluminum, and fiberglass. Steel grating tends to be the most affordable; however, its susceptibility to rust and corrosion can lead to added expenses for maintenance or replacement. Aluminum is lighter and resistant to corrosion, but often comes with a higher price tag. Fiberglass is known for its longevity and is an excellent choice for corrosive environments but is among the more expensive options.

2. Grating Type Different types of grating come with varying costs. For example, welded bar grating, which is considered the sturdiest, might be pricier than both swage-locked and pressure-locked grating due to its manufacturing complexity. Additionally, molded fiberglass grating could also contribute to higher costs depending on the specific design and load requirements.

3. Load Requirements The load the grating needs to support plays a significant role in its cost. Heavy-duty grating designed for high loads will typically be more expensive due to the additional materials and engineering involved in its design. Anticipating the load requirements early in the project can help avoid unnecessary expenditures later.

bar grating cost

4. Size and Customization The sizing of the grating can also affect the overall cost. Custom widths and lengths will generally incur higher costs compared to standard sizes. Furthermore, additional features like anti-slip surfaces, coatings for corrosion resistance, and specific finish treatments can also add to the expense.

5. Quantity and Application Bulk purchases often allow for discounts, but the specific application can also influence material choices and costs. For instance, applications that require more robust, heavy-duty grates will increase the overall project budget. Conversely, smaller or less demanding projects may allow for the use of more cost-effective options.

6. Installation Costs It's not just the price of the grating itself; installation is another significant aspect. The complexity of the installation process, as well as labor costs in your region, can impact the total expenditure. Grating that is easier to install might save on labor costs, whereas complicated installations requiring specialized skills can quickly skyrocket project costs.

Budgeting for Bar Grating

When budgeting for bar grating, it is crucial to conduct a thorough analysis of the specific needs of your project. Collecting multiple quotes from suppliers, considering both materials and installation, can help you find the best price without sacrificing quality. Planning for potential fluctuations in prices, especially for materials like steel and aluminum influenced by market conditions, can also be a wise approach.

Conclusion A Smart Investment

In conclusion, while the upfront costs associated with bar grating can seem high, it is essential to consider it as an investment. Quality bar grating can lead to reduced maintenance costs, longer lifespans, and enhanced safety in your operations. By taking into account the various factors that influence the cost—material, type, load requirements, size, and installation—you can make informed decisions that align with your budget and operational needs.

-

Welded Steel Bar Grating: The Strongest Choice for Industrial FlooringNewsMay.21,2025

-

Steel Grating for Sale: The Ultimate Anti-Slip SolutionNewsMay.21,2025

-

Steel Frame Shaker Screens: Unmatched Durability for Demanding OperationsNewsMay.21,2025

-

Shaker Screens: Your Ultimate Solution for Oil & Gas FiltrationNewsMay.21,2025

-

Press Locked Steel Grating: The Smarter Choice for Heavy-Duty FlooringNewsMay.21,2025

-

Helicopter Deck Safety Nets: Protect Your Crew and EquipmentNewsMay.21,2025