- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Steel Walkway Grating: Durable, Safe Metal Grates & Mesh

The Indispensable Role of Steel Walkway Grating in Modern Infrastructure

In an era of burgeoning industrial development and complex infrastructure projects, the demand for robust, safe, and efficient access solutions is paramount. Steel walkway grating stands as a cornerstone in this demand, providing critical support in diverse environments ranging from bustling manufacturing plants to remote oil rigs. Engineered for durability and high performance, these gratings offer an optimal combination of strength, ventilation, and slip resistance, making them a preferred choice for platforms, stair treads, and drainage covers. Their versatile design accommodates various load requirements and environmental conditions, ensuring personnel safety and operational efficiency across a multitude of industries. This comprehensive guide delves into the technical aspects, applications, and advantages of modern steel grating solutions, highlighting their crucial role in safeguarding operations and enhancing productivity.

The evolution of Steel walkway grating has been driven by continuous innovation in material science and manufacturing processes. Today's gratings are not merely structural elements but highly specialized components designed to meet stringent international standards such as ISO and ASTM. They are crucial for maintaining operational continuity in demanding sectors like petrochemicals, power generation, and wastewater treatment, where resistance to corrosion, heavy loads, and extreme temperatures is non-negotiable. As a leading manufacturer of high-quality Steel Grating, we leverage advanced technologies and decades of experience to deliver solutions that embody superior strength, longevity, and cost-effectiveness. Our products are meticulously fabricated to ensure optimal performance and compliance with industry-specific safety protocols, providing clients with unparalleled reliability and peace of mind.

Decoding the Manufacturing Process of Steel Grating

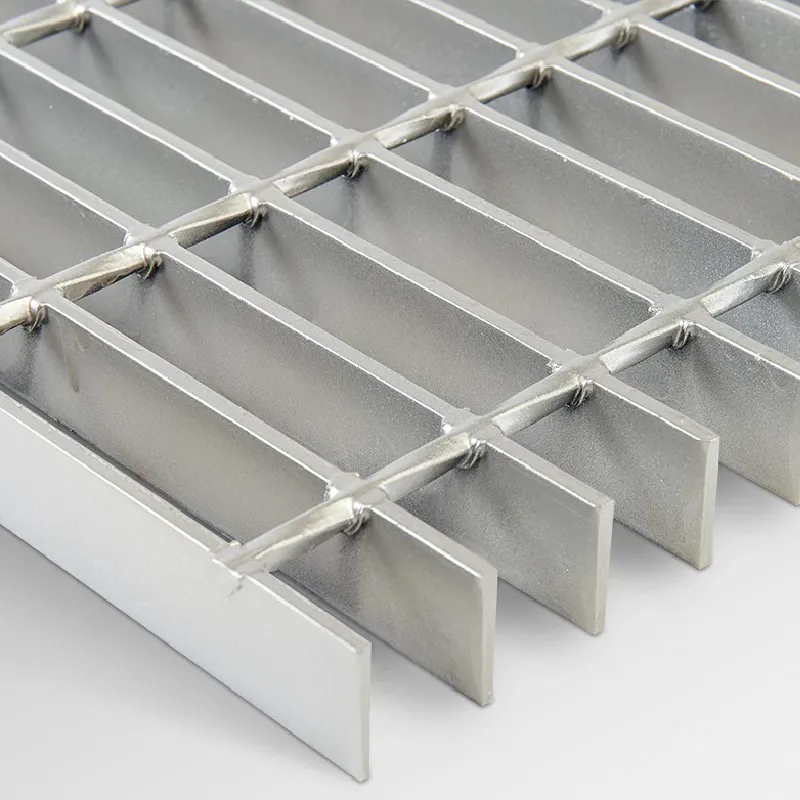

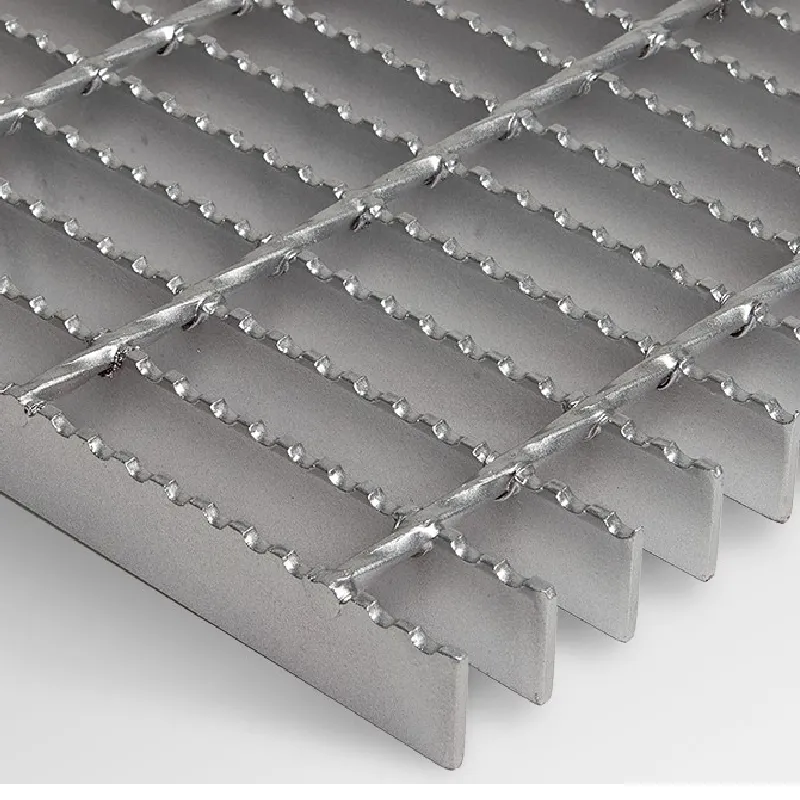

The production of high-performance steel walkway grating involves a meticulous, multi-stage process designed to ensure structural integrity and longevity. The journey begins with the careful selection of raw materials, primarily low carbon steel or stainless steel, chosen for their inherent strength and resistance to environmental factors. Common grades include Q235, Q345, or various stainless steel alloys like SS304 and SS316, each selected based on the specific application's load-bearing and corrosion resistance requirements. The manufacturing techniques typically employed include electro-forging welding, pressure locking, or swage locking. Electro-forging welding is particularly prevalent, involving the application of high current and pressure to fuse the bearing bars and cross bars, creating a robust, monolithic panel. This process ensures exceptional joint strength and durability, critical for sustained performance under heavy loads.

Post-fabrication, the gratings undergo critical finishing processes, with hot-dip galvanization being the most common and effective. This involves immersing the steel panels in molten zinc, creating a metallurgical bond that provides superior corrosion resistance, particularly crucial for outdoor or harsh industrial environments like petrochemical plants or offshore platforms. This coating, adhering to standards like ASTM A123, significantly extends the service life of the grating, often exceeding 20-30 years with proper maintenance. Quality control is integrated throughout the entire process, from raw material inspection to final product testing. Adherence to international standards such as ISO 9001 for quality management and ANSI/NAAMM MBG 531 for metal bar grating ensures that each panel meets stringent performance criteria for load capacity, deflection, and dimensional accuracy, guaranteeing optimal safety and reliability in any application.

Key Technical Specifications for Optimal Walkway Grates Performance

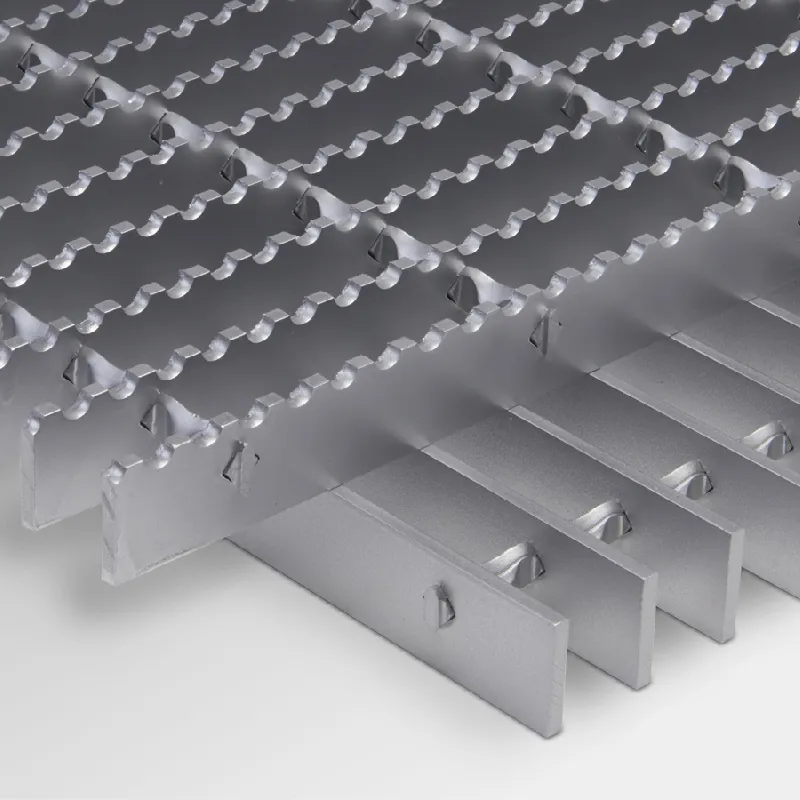

Understanding the technical specifications of metal walkways gratings is crucial for selecting the right product for specific applications. Key parameters include the bearing bar size (depth and thickness), bearing bar pitch, and cross bar pitch. The bearing bar, which carries the primary load, determines the grating's strength and span capability. Common depths range from 20mm to 100mm, with thicknesses from 3mm to 10mm. The pitch, or spacing, between bearing bars and cross bars affects the open area, load distribution, and pedestrian comfort. A tighter pitch provides higher load capacity and a finer walking surface, while a wider pitch offers better ventilation and light penetration. Surface types, such as plain or serrated, also impact performance, with serrated surfaces providing enhanced slip resistance in wet or oily conditions.

| Parameter | Description | Typical Range / Value | Relevant Standard |

|---|---|---|---|

| Material Grade | Common steel alloys used for grating fabrication. | Q235, Q345 (Mild Steel), SS304, SS316 (Stainless Steel) | ASTM A36, ASTM A1011 |

| Bearing Bar Size | Depth x Thickness of the main load-bearing bars. | 25x3mm to 100x8mm | ANSI/NAAMM MBG 531 |

| Bearing Bar Pitch | Center-to-center distance between bearing bars. | 30mm, 40mm, 60mm | ISO 9001 (Quality Control) |

| Cross Bar Pitch | Center-to-center distance between cross bars. | 50mm, 100mm | Manufacturer Specific |

| Surface Treatment | Corrosion protection applied to the grating. | Hot-Dip Galvanized, Painted, Mill Finish | ASTM A123, ISO 1461 |

| Load Capacity | Maximum weight the grating can safely support over a given span. | Varies widely (e.g., 2.5kN/m² to 10kN/m²) | Load Table Dependent on Config. |

| Open Area Percentage | The percentage of open space in the grating panel. | 60% - 90% | Calculated |

These specifications directly influence the grating’s suitability for various environments. For example, in applications requiring high load-bearing capacity over long spans, such as industrial platforms or vehicle ramps, gratings with deeper and thicker bearing bars are essential. Conversely, for pedestrian walkways in architectural settings where aesthetics and light transmission are key, a finer mesh with closer spacing might be preferred. Our expert team assists clients in navigating these technical details, providing tailored recommendations to ensure that the chosen steel walkway grating solution perfectly matches their operational needs and safety requirements, guaranteeing optimal performance and longevity.

Technical Advantages and Performance of Steel Walkway Mesh

The inherent design and material properties of steel walkway mesh offer a compelling array of technical advantages, making them the superior choice for critical industrial and commercial applications. Foremost among these is their exceptional strength-to-weight ratio. Despite being relatively lightweight, steel grating can withstand significant static and dynamic loads, minimizing the need for extensive support structures and reducing overall construction costs. This characteristic is particularly beneficial for elevated platforms and mezzanines where structural weight is a critical design consideration. Furthermore, the open grid design allows for excellent light and air penetration, which is vital in optimizing ventilation in enclosed spaces and enhancing natural illumination, contributing to energy savings and improved working conditions.

Beyond structural integrity, the performance of steel walkway grating is significantly enhanced by its superior corrosion resistance, especially when hot-dip galvanized. This protective layer ensures longevity even in highly corrosive environments, such as chemical processing plants, marine applications, or wastewater treatment facilities, where traditional materials would quickly degrade. The open mesh also prevents the accumulation of water, snow, debris, or hazardous liquids, reducing slip hazards and facilitating easy maintenance. This self-cleaning property minimizes labor costs associated with routine cleaning and ensures continuous operational safety. The high durability and minimal maintenance requirements translate into substantial long-term cost savings, reinforcing steel grating as a highly cost-effective and reliable solution for long-term infrastructure investments.

Versatile Applications and Customization of Walkway Grates

The adaptability of walkway grates makes them indispensable across a wide spectrum of industries. In the energy sector, including power plants and oil & gas facilities, they form essential platforms, stairways, and mezzanines, providing safe access for maintenance crews and operational personnel. Their open structure is also critical in areas where light and heat dissipation are paramount, such as boiler rooms or turbine halls. In chemical and petrochemical plants, specialized corrosion-resistant gratings, often stainless steel or hot-dip galvanized, are used for containment areas, process walkways, and loading docks. The water treatment industry relies on them for clarifier walkways, filter media supports, and access bridges due to their excellent drainage capabilities and resistance to continuous moisture exposure. Beyond heavy industry, they are increasingly specified for architectural applications, including facades, sunscreens, and urban landscaping, valued for their modern aesthetic and robust performance.

Customization is a cornerstone of our service offering for steel walkway grating. Recognizing that every project has unique requirements, we provide comprehensive tailored solutions. This includes custom dimensions and shapes to fit irregular layouts, specialized cuts for pipe penetrations or column cutouts, and various banding options for edge protection. Clients can specify different material grades, such as high-strength carbon steel for heavy industrial use or marine-grade stainless steel for coastal environments. Surface treatments can also be customized, from standard hot-dip galvanization to specialized paint coatings for aesthetic or additional corrosion protection. Our engineering team works closely with clients from concept to completion, performing detailed load analysis and deflection calculations to ensure that the custom-fabricated gratings meet the exact structural and operational demands of their specific application, guaranteeing optimal performance and safety.

Ensuring Quality and Reliability: Industry Standards & Certifications

In the manufacturing of steel walkway grating, adherence to stringent international standards is not merely a compliance requirement but a fundamental commitment to quality, safety, and reliability. We rigorously follow globally recognized benchmarks, ensuring our products meet and often exceed performance expectations. Key among these are the ISO 9001:2015 Quality Management System certification, which attests to our systematic approach to consistent product quality and customer satisfaction throughout the manufacturing process. Furthermore, our products conform to various ASTM (American Society for Testing and Materials) standards, specifically those pertaining to material properties like ASTM A36 for structural steel and ASTM A123 for zinc (hot-dip galvanized) coatings on iron and steel products. These standards ensure the raw materials possess the required strength and the finished products offer superior corrosion protection.

Beyond material and coating standards, we also comply with critical performance specifications like ANSI/NAAMM MBG 531 (American National Standards Institute/National Association of Architectural Metal Manufacturers Metal Bar Grating Manual). This manual provides comprehensive guidelines for the design, fabrication, and installation of metal bar grating, including load tables and deflection limits. By aligning with these authoritative standards, we demonstrate our commitment to delivering products that are not only structurally sound but also safe for intended use, minimizing risks and maximizing operational efficiency. Our extensive service record of over 20 years in the industry, coupled with partnerships with major engineering and construction firms, further solidifies our position as a trusted and authoritative provider of high-quality steel walkway grating solutions for demanding industrial applications worldwide.

Case Studies and Client Successes with Steel Grating

Our expertise in providing high-quality steel walkway grating is validated by numerous successful projects across diverse industries. One notable case involved a large-scale petrochemical complex in the Middle East, requiring extensive platforms and access ways for highly corrosive environments. We supplied over 1,500 square meters of hot-dip galvanized steel grating, specifically designed with a serrated surface for enhanced slip resistance. The client reported significant improvements in safety and ease of maintenance, with the grating performing exceptionally well under continuous exposure to aggressive chemicals and extreme temperatures. This project underscored our capability to deliver customized, high-performance solutions within challenging logistical and environmental parameters, adhering to strict project timelines and quality controls demanded by the oil and gas sector.

Another key success story is our contribution to a major municipal wastewater treatment facility expansion in North America. This project demanded durable and corrosion-resistant metal walkways gratings for clarifier tanks, filter beds, and access bridges, areas constantly exposed to moisture, chemicals, and biological agents. We supplied stainless steel grating (SS316L) to ensure maximum longevity and minimal maintenance. Our customized fabrication included precise cutouts for piping and machinery, ensuring seamless integration with existing infrastructure. The facility managers praised the ease of installation and the robust, long-lasting nature of the gratings, noting a significant reduction in long-term operational costs associated with material degradation and replacement. These examples highlight our commitment to providing tailored, high-performance grating solutions that meet the exacting demands of our global clientele, delivering tangible value and operational excellence.

Frequently Asked Questions (FAQ) about Steel Grating

Q1: What is the typical service life of steel walkway grating?

A1: The service life of steel walkway grating largely depends on the material, surface treatment, and environmental conditions. Hot-dip galvanized steel grating can last 20-30 years or even longer in typical outdoor industrial environments, thanks to its robust zinc coating which provides excellent corrosion resistance. Stainless steel grating offers even greater longevity in highly corrosive or sterile environments. Proper installation and minimal maintenance further extend its lifespan.

Q2: How do you ensure the load-bearing capacity of your gratings?

A2: We ensure load-bearing capacity through a combination of engineering design, material selection, and rigorous testing. Our design process adheres to international standards such as ANSI/NAAMM MBG 531, which provides load tables based on bearing bar size, spacing, and span. We use certified raw materials and employ advanced manufacturing techniques like electro-forging welding. Before dispatch, panels undergo stringent quality checks, including visual inspection, dimensional verification, and sample load testing to confirm they meet specified load requirements and deflection limits.

Q3: Can steel walkway grating be used in corrosive environments?

A3: Absolutely. For corrosive environments, hot-dip galvanized steel grating offers excellent protection against rust and chemical degradation. For extreme conditions, such as those found in marine, chemical, or wastewater treatment facilities, we recommend using stainless steel grating (e.g., SS304 or SS316). These materials are specifically designed to resist a wide range of corrosive agents, ensuring long-term structural integrity and safety.

Q4: What is your typical delivery timeframe and warranty policy?

A4: Our delivery timeframe for steel walkway grating typically ranges from 2 to 6 weeks, depending on the complexity and volume of the order. We maintain efficient production schedules and robust logistics to ensure timely dispatch. As for our warranty, we provide a standard 5-year warranty against manufacturing defects and material failures under normal operating conditions, reflecting our confidence in the quality and durability of our Steel Grating products. Our dedicated customer support team is always available for post-sales assistance and technical queries.

Conclusion: Investing in Durable and Efficient Walkway Grates

In summary, the strategic implementation of high-quality steel walkway grating is a critical investment for any industrial, commercial, or public infrastructure project. These meticulously engineered components provide unparalleled structural integrity, safety, and longevity, offering superior performance compared to alternative materials. From the selection of robust steel grades to advanced electro-forging techniques and comprehensive hot-dip galvanization, every step in the manufacturing process is designed to deliver a product that withstands the most demanding conditions, ensuring long-term operational efficiency and minimizing maintenance costs. The versatility of walkway grates allows for extensive customization, enabling precise solutions for unique project requirements, whether for heavy industrial platforms, corrosive marine environments, or aesthetic architectural applications.

Our commitment to adhering to international standards like ISO 9001 and ASTM, combined with our decades of industry experience, positions us as a trusted partner in delivering reliable steel walkway grating solutions. By choosing a reputable manufacturer with a proven track record, businesses can ensure access to products that not only meet current safety and performance regulations but also contribute to a sustainable and resilient infrastructure for decades to come. Investing in our Steel Grating signifies a commitment to uncompromised safety, enduring quality, and intelligent design, safeguarding your operations and personnel while optimizing long-term capital expenditures. Our team is ready to assist you in selecting and customizing the perfect grating solution for your next challenging project.

References

- American Society for Testing and Materials (ASTM). "ASTM A36/A36M, Standard Specification for Carbon Structural Steel."

- American Society for Testing and Materials (ASTM). "ASTM A123/A123M, Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products."

- International Organization for Standardization (ISO). "ISO 9001:2015, Quality Management Systems – Requirements."

- National Association of Architectural Metal Manufacturers (NAAMM). "ANSI/NAAMM MBG 531, Metal Bar Grating Manual."

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025