- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Premium Shale Shaker Screen Mesh | Durable & Efficient

Advancing Drilling Efficiency with Premier Shale Shaker Screens

In the highly demanding oil and gas drilling industry, efficient solids control is paramount for optimizing drilling operations and minimizing costs. The shale shaker screen stands as a critical component in this process, serving as the primary barrier for separating drilled cuttings from valuable drilling fluids. As global energy demands evolve, the industry increasingly seeks advanced screen technologies that offer superior fluid recovery, longer service life, and enhanced operational stability. This push is driven by the need to reduce environmental impact, improve safety, and achieve greater economic efficiencies in both onshore and offshore drilling projects, underscoring the vital role of robust solids control equipment.

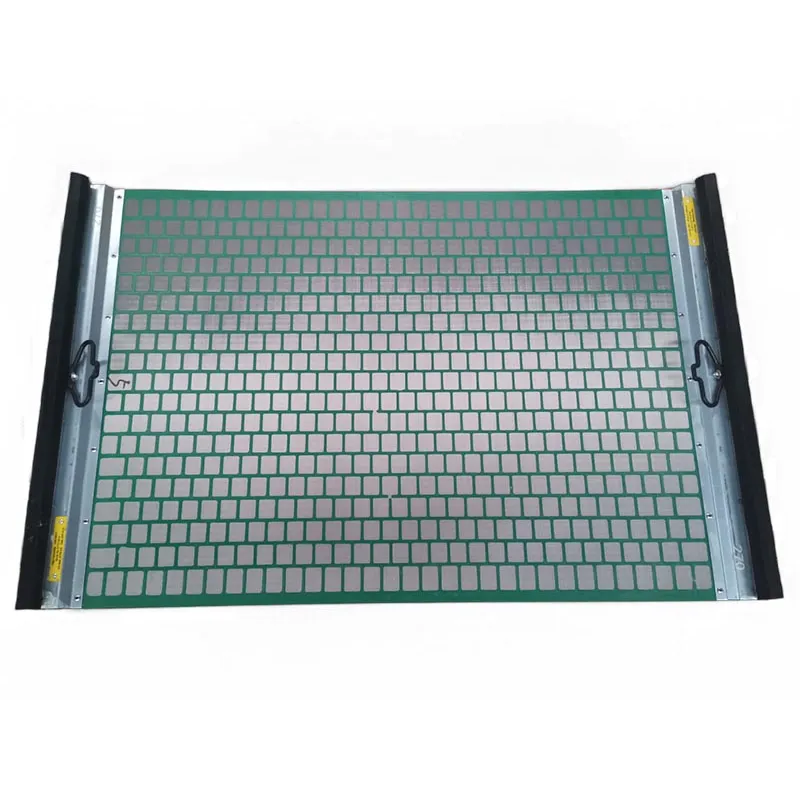

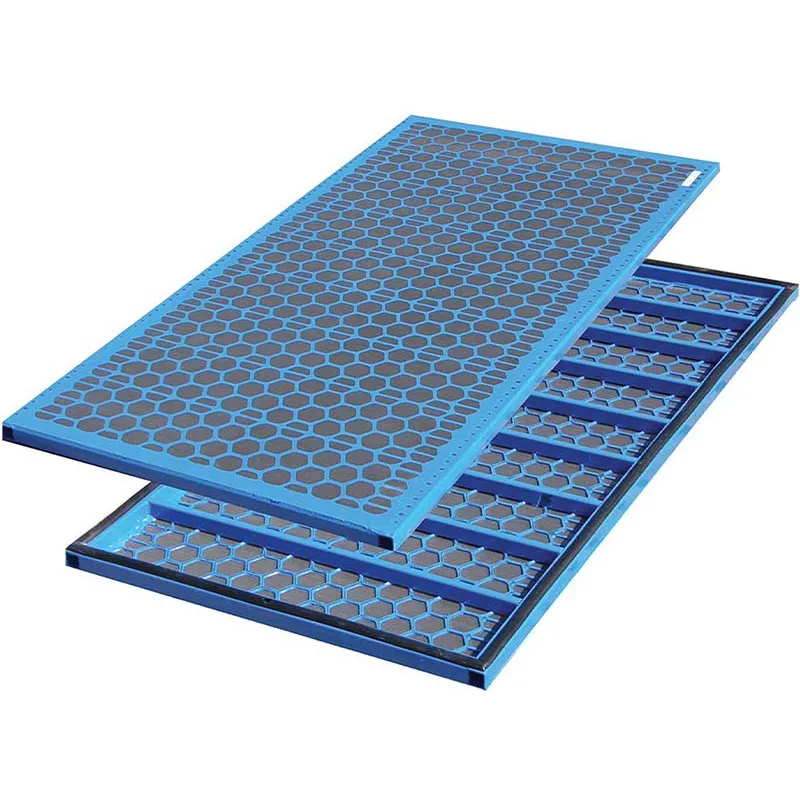

Modern shale shaker screen designs focus on maximizing conductance and non-blanked screen area, which are crucial for processing high fluid volumes without sacrificing separation efficiency. Key industry trends include the adoption of composite frames for lighter weight and increased durability, multi-layered mesh configurations for finer separation, and innovative tensioning systems that simplify installation and maintenance. The continuous development in shale shaker screen mesh technology is directly contributing to significant advancements in drilling fluid management, enabling operators to achieve higher drilling speeds and reduce overall operational expenditure, solidifying its role as an indispensable tool in contemporary drilling practices and influencing the competitive shale shaker screen price landscape globally.

Technical Parameters and Core Functionality

The performance of a shale shaker screen is defined by several key technical parameters, each critical for effective solids control. The API Recommended Practice 13C (API RP 13C) serves as the industry standard for screen performance classification, ensuring consistency and reliability across different manufacturers. This standard specifies mesh cut point (D100), conductance, and non-blanked screen area (NBSA). The D100, or nominal cut point, indicates the smallest particle size that can be effectively separated by the screen, while conductance reflects the screen's capacity to process drilling fluid, measured in kilodarcies per unit area. A higher conductance generally translates to faster processing rates and reduced fluid bypass, optimizing drilling fluid recovery.

Understanding these parameters is essential for selecting the appropriate shale shaker screen for specific drilling conditions. For instance, screens with finer mesh are used for separating smaller particles, typically in later stages of the solids control process, while coarser screens are employed in initial stages for bulk removal. The non-blanked area, representing the open area of the screen available for fluid flow, directly impacts processing efficiency and minimizes blinding. Advancements in composite frame technology and specialized mesh weaving techniques continue to optimize these parameters, leading to superior fluid-solid separation and extended screen life, contributing significantly to a reduced overall shale shaker screen price over the operational lifespan.

Manufacturing Excellence and Quality Assurance

The manufacturing of high-performance shale shaker screen involves a meticulous process designed to ensure durability, efficiency, and precise separation. It typically begins with the selection of premium materials, primarily high-grade stainless steel wire cloth (SS304, SS316, or SS316L) for its exceptional corrosion resistance, high tensile strength, and mechanical robustness. The wire mesh, often multi-layered with different opening sizes (e.g., fine filter layer, support layer, protective layer), is then precisely cut and stretched over a robust frame, which can be made from high-strength steel or advanced composite materials. Composite frames are increasingly favored due to their lighter weight, enhanced vibration absorption, and superior resistance to wear and tear compared to traditional steel frames, prolonging screen life.

Key manufacturing processes include precision cutting using CNC machinery, advanced welding techniques (such as resistance welding for mesh layers to prevent delamination), and injection molding or bonding for composite frames to ensure structural integrity. After assembly, each shale shaker screen undergoes rigorous quality control. This includes visual inspections, precise dimensional checks (e.g., flatness, tension), and performance testing to verify compliance with international standards such as ISO 9001 for quality management and API RP 13C for screen performance characteristics. This stringent testing ensures optimal service life, often ranging from 300 to 600 drilling hours under typical conditions, and guarantees superior separation efficiency in diverse applicable industries like petrochemicals, metallurgy, mining, and municipal water treatment. The meticulous adherence to these standards is what differentiates a top-tier shale shaker screen factory.

Application Scenarios and Performance Advantages

Shale shaker screens are indispensable across a wide spectrum of drilling applications, from conventional onshore and offshore oil and gas drilling to specialized operations like horizontal directional drilling (HDD), geothermal drilling, and mining exploration. Their primary role is to efficiently remove solids from drilling fluid (mud), preventing premature wear and tear on expensive drilling equipment, reducing mud consumption by enabling fluid re-use, and improving overall drilling performance through optimized fluid properties. In highly corrosive environments, such as those encountered in deep drilling or challenging geological formations, the anti-corrosion properties of high-grade stainless steel mesh ensure extended screen longevity and consistent operational integrity, significantly reducing the frequency of costly replacements and downtime.

Beyond their robust construction, modern shale shaker screens deliver substantial operational advantages. Their optimized design, featuring high non-blanked screen area and improved fluid conductance, contributes to notable energy savings by allowing drilling mud to pass through more efficiently, reducing the workload on pumps and other circulation equipment. This enhanced efficiency not only lowers operational costs but also translates into less drilling fluid loss, quicker penetration rates, and a more environmentally responsible drilling process by minimizing waste. Client feedback and numerous service cases demonstrate that high-performance screens lead to superior solids control, reduced waste disposal volumes, and a lower total cost of ownership for drilling projects globally, including those benefiting from the technical prowess of a leading shale shaker screen China supplier.

Selecting a Manufacturer and Customization Solutions

Choosing the right shale shaker screen factory is crucial for ensuring product quality, reliable supply, and expert support. Key considerations include the manufacturer's unwavering adherence to international standards (e.g., ISO, API RP 13C), their proven track record for continuous innovation, robust production capacity, and the ability to provide comprehensive pre-sales and after-sales technical support. Reputable manufacturers often invest heavily in research and development to create screens that cater to emerging drilling challenges, such as those involving ultra-deep wells, highly viscous drilling fluids, or specific environmental regulations. Evaluating a manufacturer’s experience and expertise in producing a wide range of shale shaker screen mesh types is also vital for ensuring seamless compatibility with existing shaker models and diverse operational requirements.

Leading manufacturers understand that modern drilling operations frequently require tailored solutions to optimize performance. Therefore, offering extensive customization options is a hallmark of a proficient supplier. This can range from specific mesh configurations to accommodate unique geological conditions or fluid properties, custom frame dimensions to fit older or specialized shaker models, and even bespoke material compositions for extreme temperature, pressure, or highly corrosive environments. Engaging with a manufacturer that provides robust technical consultation and design capabilities ensures that the customized shale shaker screen not only fits perfectly but also delivers optimal performance, providing a distinct competitive edge and potentially better long-term cost efficiencies.

Trustworthiness, Support, and FAQ

Commitment to Our Customers

Our commitment to customer satisfaction extends far beyond simply delivering high-quality shale shaker screen products. We prioritize transparent communication, reliable logistics, and comprehensive after-sales support to foster enduring partnerships built on trust and mutual success. Each product is rigorously tested and backed by a robust quality assurance program and compliance with industry-leading certifications like ISO 9001:2015, ensuring that every screen meets stringent performance, durability, and safety standards. Our dedicated technical support team is readily available to assist with expert product selection, provide detailed installation guidance, and offer prompt troubleshooting assistance, ensuring seamless integration and optimal performance within your drilling operations.

Delivery Cycle and Warranty

Understanding the time-sensitive nature of drilling projects, we maintain efficient production schedules and robust global supply chain management to ensure timely delivery of your shale shaker screen orders. Typical delivery cycles for standard products range from 7-14 business days, with expedited shipping options available for urgent requirements, ensuring minimal operational downtime. For highly customized solutions, lead times are meticulously discussed and mutually agreed upon during the initial technical consultation and quotation phase to meet your project timelines. All our shale shaker screens come with a comprehensive warranty against manufacturing defects and material failures, underscoring our unwavering confidence in product quality and providing complete peace of mind to our valued clients. Detailed warranty policies are always provided with each quotation and final delivery.

Frequently Asked Questions (FAQ)

-

Q: How do I determine the correct mesh size for my application?

A: The ideal mesh size for your shale shaker screen depends critically on the type of drilling fluid being used, the desired solids removal efficiency, and the specific geological formations being drilled. Our experienced technical team can provide expert consultation to assist you in selecting the precise API mesh size that best suits your unique operational needs based on your mud properties and target particle separation goals. -

Q: What are the advantages of composite frames over traditional steel frames?

A: Composite frames for shale shaker screen offer significant benefits, including substantially lighter weight for easier handling, enhanced durability against impacts, superior vibration dampening for reduced wear on shakers, and exceptional corrosion resistance, collectively leading to extended service life and reduced operational noise compared to traditional steel frames. -

Q: Can you provide customized screens for non-standard or older shaker models?

A: Yes, as a leading shale shaker screen factory with extensive engineering capabilities, we specialize in providing highly customized solutions. Please provide your specific shaker model specifications, detailed dimensional requirements, or even technical drawings, and our dedicated engineering team will expertly design and manufacture screens precisely tailored to your unique requirements, ensuring perfect fit and optimal performance. -

Q: What is the typical service life of a shale shaker screen?

A: The service life of a shale shaker screen varies significantly depending on several factors, including abrasive characteristics of the drilled solids, drilling fluid properties, shaker vibration intensity, and overall operational practices. Generally, our screens are engineered for a robust 300-600 drilling hours under normal operating conditions. Adhering to proper maintenance procedures and timely replacement practices are crucial for maximizing their longevity and ensuring consistent performance.

Authoritative References

- American Petroleum Institute. API RP 13C: Recommended Practice for Drilling Fluid Processing Systems Evaluation.

- International Organization for Standardization. ISO 9001:2015: Quality management systems — Requirements.

- SPE (Society of Petroleum Engineers) Journal articles on drilling fluid solids control and separation technologies.

- Academic research papers on advanced materials for filtration and separation in the oil and gas industry.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025