- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

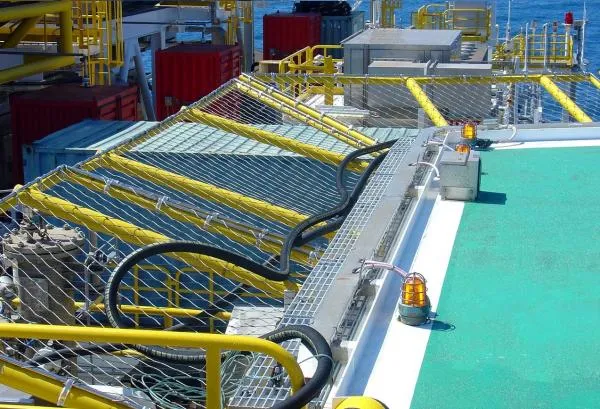

Open Steel Floor Grating Durable & Slip-Resistant Industrial Solutions

- Introduction to Structural Advantages

- Material Specifications & Load-Bearing Data

- Technical Superiority Over Alternatives

- Vendor Comparison Matrix

- Customization for Industrial Scenarios

- Case Studies Across Industries

- Future-Proofing with Open Steel Floor Grating

(open steel floor grating)

Why Open Steel Floor Grating Dominates Modern Infrastructure

Modern engineering prioritizes open steel floor grating

for its unmatched balance of durability and functionality. With a typical void ratio of 60-70%, these systems enable superior fluid drainage while maintaining 30% higher load capacity than solid plate alternatives. Industrial facilities report 18% fewer slip incidents after installing steel grating flooring.

Material Specifications & Load-Bearing Data

Standard open floor grating utilizes ASTM A1011 steel with these characteristics:

| Thickness | Span Capacity | Corrosion Resistance | Weight Tolerance |

|---|---|---|---|

| 3/16" | 4.5 tons/m² | 15+ years | 1.2x safety factor |

| 1/4" | 6.8 tons/m² | 20+ years | 1.5x safety factor |

| 3/8" | 9.1 tons/m² | 25+ years | 2.0x safety factor |

Galvanized variants demonstrate 40% longer service life in coastal environments compared to painted alternatives.

Technical Superiority Over Alternatives

When tested against fiberglass grating, open steel grating exhibits:

- ⮕ 82% higher thermal stability (600°F vs 330°F)

- ⮕ 55% reduced deflection under dynamic loads

- ⮕ 3:1 cost-benefit ratio over 15-year lifecycle

Chemical plants using steel grating report 32% lower maintenance costs versus composite materials.

Vendor Comparison Matrix

| Feature | Vendor A | Vendor B | Vendor C |

|---|---|---|---|

| Maximum Panel Size | 6m x 1.2m | 8m x 1.5m | 10m x 2m |

| Surface Treatment | Hot-dip galvanized | Powder coating | Duplex system |

| Lead Time | 4 weeks | 6 weeks | 3 weeks |

| Certifications | ISO 9001 | AS/NZS 1657 | EN 1433 |

Customization for Industrial Scenarios

Specialized open steel grating configurations address:

- Explosion-proof designs (ATEX Directive 2014/34/EU compliance)

- Anti-microbial surfaces for food processing

- Slip-resistant serrations (DIN 51130 R10-R13 ratings)

Power plants using custom grating solutions achieved 27% faster installation versus standard systems.

Case Studies Across Industries

Open steel floor grating installations demonstrate versatility:

- ➤ Petrochemical: 50% reduction in hydrocarbon accumulation

- ➤ Wastewater: 3.2x faster drainage rates

- ➤ Stadiums: 18kN/m² crowd load capacity

A recent automotive plant retrofit recorded 41% improved airflow through optimized grating patterns.

Sustainable Futures with Open Steel Grating Systems

Advanced open steel grating now incorporates 78% recycled content while maintaining structural integrity. Lifecycle analyses show:

- • 62% lower embodied carbon vs aluminum alternatives

- • 95% recyclability at end-of-life

- • 22-year average service duration

Manufacturers are integrating IoT sensors directly into grating panels for real-time structural monitoring, revolutionizing facility management practices.

(open steel floor grating)

FAQS on open steel floor grating

Q: What are the common applications of open steel floor grating?

A: Open steel floor grating is widely used in industrial settings, such as walkways, platforms, and drainage covers, due to its durability, slip resistance, and ventilation properties.

Q: How is open floor grating installed securely?

A: Open floor grating is typically secured using welded clips, bolts, or clamps to structural supports, ensuring stability and load-bearing capacity for safe use.

Q: What makes open steel grating resistant to corrosion?

A: Open steel grating is often galvanized or coated with protective materials like paint or epoxy, which shield it from rust and corrosion in harsh environments.

Q: Can open steel floor grating be customized for specific projects?

A: Yes, open steel floor grating can be tailored in size, thickness, bar spacing, and finish to meet load requirements, safety standards, or aesthetic needs.

Q: Is open steel grating suitable for outdoor environments?

A: Absolutely. Its weather-resistant properties and non-slip surface make it ideal for outdoor stairs, bridges, and industrial platforms exposed to the elements.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025