- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

bar grating weight

Understanding Bar Grating Weight An Overview

Bar grating is a widely used material in various industries, including construction, manufacturing, and transportation. Its applications range from flooring and platforms to walkways and drain covers. One of the key considerations in the selection and implementation of bar grating is its weight, which can significantly influence installation, structural integrity, and overall project costs. In this article, we will explore the concept of bar grating weight, its determinants, and its implications on project management.

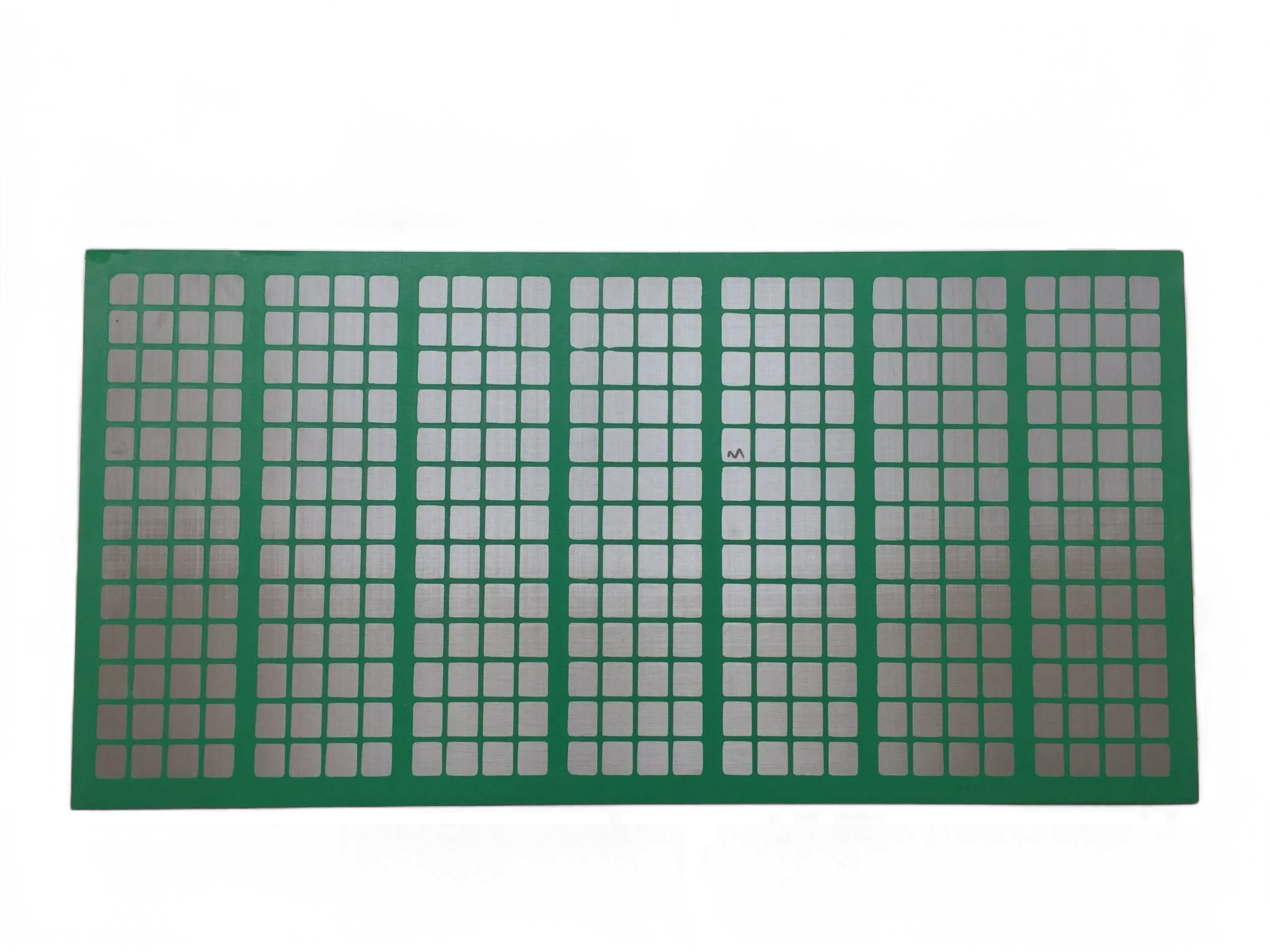

What is Bar Grating?

Bar grating is a construction component made from metal or fiberglass, consisting of a series of parallel bars that are joined by crossbars. This creates a grid-like structure that allows for maximum ventilation, light penetration, and drainage. Common materials for bar grating include steel, aluminum, and fiberglass, each offering varying strengths, weights, and corrosion resistances.

Determinants of Bar Grating Weight

The weight of bar grating is influenced by several factors 1. Material Composition The type of material used significantly affects the weight. For instance, steel grating is typically heavier than aluminum or fiberglass due to its density and strength. 2. Bar Dimensions The size of the bars, including their thickness and width, directly impacts the overall weight. Thicker bars provide increased load-bearing capacity but also contribute to additional weight. 3. Spacing The distance between the bars, referred to as spacing, can also affect weight. Closer spacing results in a heavier grating, while wider spacing may lighten the structure. 4. Type of Grating Different types of bar grating, such as plain, serrated, or case-hardened, can vary in weight characteristics. Each type has its own unique strength-to-weight ratios.

Calculating Bar Grating Weight

The weight of bar grating can be calculated by determining the weight per square foot and multiplying it by the total area of the grating required. A typical formula used is

\[ \text{Weight} = \text{Weight per Sq. Ft} \times \text{Area} \]

bar grating weight

Where the weight per square foot is determined by the material type and the dimensions of the bar grating. Manufacturers often provide these specifications, which make it easier for engineers and project managers to estimate the total weight during project design.

Implications of Bar Grating Weight

1. Installation The weight of bar grating impacts installation logistics. Heavier grating may require more robust handling equipment and more manpower for installation, which can add costs to a project. Lightweight materials like aluminum or fiberglass can simplify installation, particularly in remote or hard-to-access locations.

2. Load-Bearing Capacity Understanding the weight of bar grating is crucial when considering its load-bearing capacity. Structural integrity relies on the proper selection of grating type and material to ensure that it can support expected loads without bending or breaking.

3. Transport and Storage On a broader scale, the weight of bar grating affects transport logistics and storage requirements. Heavier materials require stronger transport vehicles and may incur higher shipping costs. Proper storage systems must also be in place to manage the weight during stockpiling.

4. Cost Considerations While lightweight materials may have a higher upfront cost, the overall savings in transportation and installation can make them more economical in the long run. Conversely, cheaper, heavier materials may save money initially but increase costs later due to handling and installation difficulties.

Conclusion

In conclusion, understanding the weight of bar grating is essential for effective project planning and execution. Factors such as material composition, bar dimensions, and spacing significantly influence its weight, which in turn affects installation, load-bearing capacity, transport logistics, and overall project costs. By accurately calculating and considering the weight of bar grating during the selection process, engineers and contractors can optimize their projects for efficiency and safety, ultimately leading to more successful outcomes.

-

Welded Steel Bar Grating: The Strongest Choice for Industrial FlooringNewsMay.21,2025

-

Steel Grating for Sale: The Ultimate Anti-Slip SolutionNewsMay.21,2025

-

Steel Frame Shaker Screens: Unmatched Durability for Demanding OperationsNewsMay.21,2025

-

Shaker Screens: Your Ultimate Solution for Oil & Gas FiltrationNewsMay.21,2025

-

Press Locked Steel Grating: The Smarter Choice for Heavy-Duty FlooringNewsMay.21,2025

-

Helicopter Deck Safety Nets: Protect Your Crew and EquipmentNewsMay.21,2025