- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

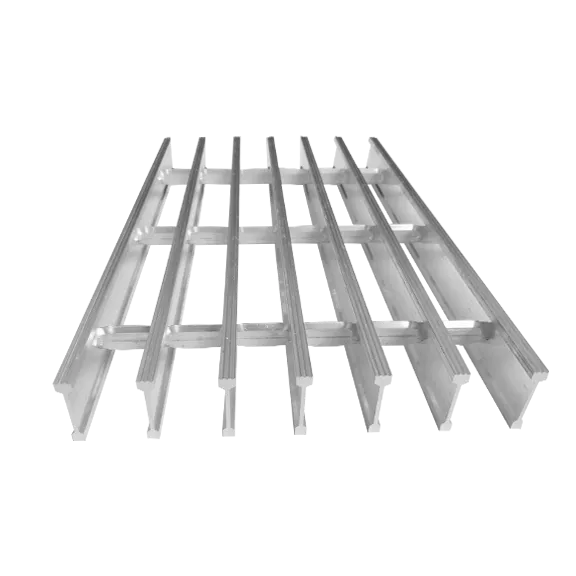

aluminum grating manufacturers

The Rise of Aluminum Grating Manufacturers A Comprehensive Overview

In recent years, the industrial landscape has seen a significant shift towards the adoption of aluminum products, particularly in the construction and engineering sectors. Among the various applications of aluminum, aluminum grating has emerged as a versatile and durable solution for many needs. This article explores the growing industry of aluminum grating manufacturers, their benefits, production processes, and applications.

Understanding Aluminum Grating

Aluminum grating is a grid-like structure used for flooring, walkways, platforms, and more. It is primarily made from aluminum alloy, which offers numerous advantages over traditional materials like steel or fiberglass. The lightweight nature of aluminum makes it easy to handle and install, while its resistance to corrosion ensures longevity even in harsh environments.

Benefits of Aluminum Grating

1. Durability and Strength Aluminum grating is designed to withstand heavy loads while remaining structurally sound. It can support substantial weights and is often used in industrial settings where safety and reliability are paramount.

2. Corrosion Resistance One of the most significant advantages of aluminum is its natural resistance to corrosion. Unlike steel, which can rust over time, aluminum can withstand exposure to moisture, chemicals, and other harsh conditions without compromising its structural integrity.

3. Lightweight The lightweight nature of aluminum makes grating easy to transport and install, reducing labor costs and enhancing overall efficiency in construction projects.

4. Customization Many aluminum grating manufacturers offer a wide range of customization options, allowing clients to specify dimensions, patterns, and finishes that suit their unique needs. This flexibility makes aluminum grating suitable for various applications, from industrial facilities to commercial buildings.

5. Eco-Friendly Aluminum is a recyclable material, making it an environmentally friendly choice for construction. Manufacturers often utilize recycled aluminum in their products, contributing to sustainability and reducing the ecological footprint.

The Manufacturing Process

aluminum grating manufacturers

The production of aluminum grating involves several key steps

1. Material Selection High-quality aluminum alloys are chosen based on the specific requirements of the grating. Common alloys include 6061 and 6063, known for their strength and corrosion resistance.

2. Fabrication The aluminum is then cut, shaped, and welded into the desired grating pattern. This process may include creating openings and drainage slots for added functionality.

3. Finishing To enhance the appearance and durability of the grating, various finishing techniques such as anodizing or powder coating are applied. These finishes not only improve aesthetics but also increase resistance to wear and corrosion.

4. Quality Control After production, the grating undergoes rigorous quality checks to ensure it meets industry standards and specifications. This step is crucial to guarantee the safety and reliability of the final product.

Applications of Aluminum Grating

Aluminum grating is utilized across a diverse range of industries and applications

- Industrial Facilities Used for walkways, platforms, and drainage systems in manufacturing plants and warehouses. - Commercial Buildings Provides flooring solutions for retail spaces, office buildings, and public areas. - Marine Applications Ideal for docks, piers, and boat ramps due to its corrosion resistance in saline environments. - Architectural Features Adds aesthetic value in modern construction designs, such as facades and decorative elements.

Conclusion

The demand for aluminum grating is on the rise, driven by its numerous advantages and versatility. As industries seek safer and more efficient solutions, aluminum grating manufacturers are poised to play a crucial role in shaping the future of construction and engineering. With ongoing advancements in technology and sustainability practices, the aluminum grating market is expected to flourish, providing innovative products that meet the evolving needs of various sectors. Whether for industrial use or architectural design, aluminum grating stands out as a durable, lightweight, and environmentally friendly option that promises resilience and functionality.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025