- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Јан . 23, 2025 02:30

Back to list

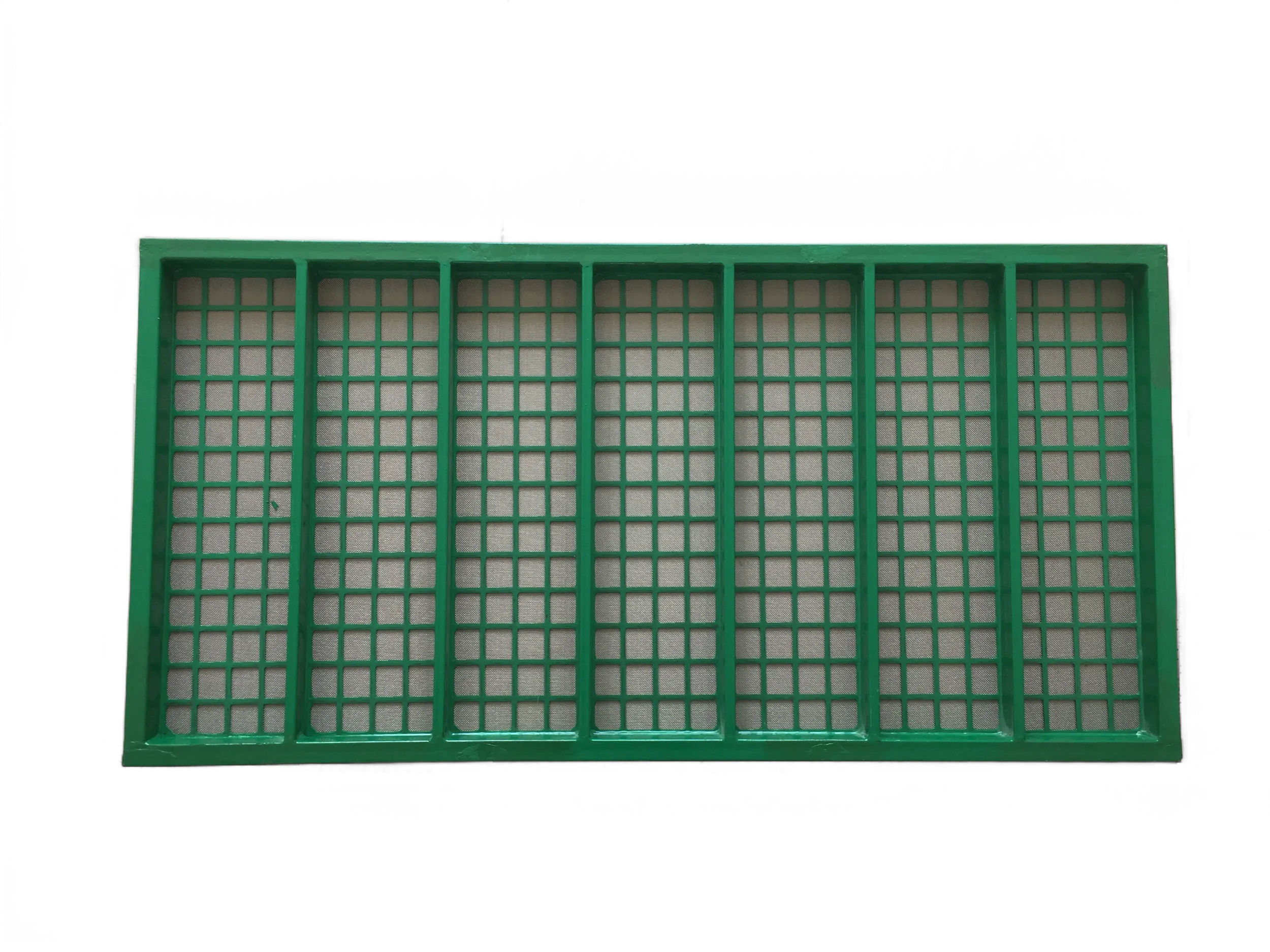

steel walkway grating

When it comes to construction and industrial applications, steel grating is often the material of choice thanks to its durability, strength, and versatility. Its applications are numerous, ranging from platforms and walkways to stair treads and trench covers. However, one critical aspect that often concerns engineers and builders is the weight of steel grating per square foot. Understanding this factor is essential for both safety and structural integrity, as well as for optimizing cost and material handling efficiency.

The weight per square foot has implications beyond the immediate concerns of handling and installation. It affects the overall weight load borne by the structural framework supporting the grating. Overloading can lead to deflection or even mounting failure, especially in dynamic load situations such as industrial flooring used by heavy machinery or foot traffic. For those managing construction and industrial operations, strategic planning around the weight of steel grating optimizes not only structural effort but cost efficiency. Transport and labor costs are tied directly to material weight. In addition, lighter gratings may reduce the need for additional structural support components, thereby simplifying design and decreasing overall expenses. Equally important is the factor of safety and compliance with regulatory standards. Building codes and safety regulations often stipulate specific weight capacities for grating, taking into account its role in supporting people or objects. Meeting these specific requirements isn't just a matter of adherence to legal mandates but of ensuring the safety and well-being of users and maintenance personnel. Professional expertise and the availability of comprehensive data are critical in making informed choices regarding weight specifications. Given these variables and implications, expertise in material science, civil engineering, and architectural design becomes key in selecting the suitable grating weight for any specific application. Therefore, understanding the weight per square foot of steel grating is not merely a technical consideration but a comprehensive requirement impacting cost, safety, and design efficiency. As trends continue to shift towards sustainable and efficient construction practices, the role of accurate material specification becomes even more pronounced. For industry professionals and buyers, this translates into informed decision-making that fosters the successful completion of projects tailored to specific functional, economic, and regulatory needs.

The weight per square foot has implications beyond the immediate concerns of handling and installation. It affects the overall weight load borne by the structural framework supporting the grating. Overloading can lead to deflection or even mounting failure, especially in dynamic load situations such as industrial flooring used by heavy machinery or foot traffic. For those managing construction and industrial operations, strategic planning around the weight of steel grating optimizes not only structural effort but cost efficiency. Transport and labor costs are tied directly to material weight. In addition, lighter gratings may reduce the need for additional structural support components, thereby simplifying design and decreasing overall expenses. Equally important is the factor of safety and compliance with regulatory standards. Building codes and safety regulations often stipulate specific weight capacities for grating, taking into account its role in supporting people or objects. Meeting these specific requirements isn't just a matter of adherence to legal mandates but of ensuring the safety and well-being of users and maintenance personnel. Professional expertise and the availability of comprehensive data are critical in making informed choices regarding weight specifications. Given these variables and implications, expertise in material science, civil engineering, and architectural design becomes key in selecting the suitable grating weight for any specific application. Therefore, understanding the weight per square foot of steel grating is not merely a technical consideration but a comprehensive requirement impacting cost, safety, and design efficiency. As trends continue to shift towards sustainable and efficient construction practices, the role of accurate material specification becomes even more pronounced. For industry professionals and buyers, this translates into informed decision-making that fosters the successful completion of projects tailored to specific functional, economic, and regulatory needs.

Share

Prev:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025