- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Јан . 16, 2025 00:42

Back to list

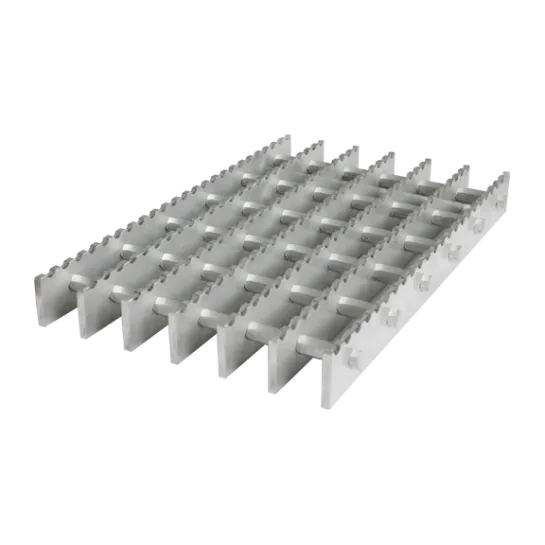

grating types

Exploring the Diverse Types of Gratings An Expert Guide

Plastic Gratings Cost-Effective and Corrosion-Resistant Plastic gratings stand out due to their affordability and corrosion-resistant properties. Used mainly in decorative applications, light-duty pedestrian areas, and corrosive environments, they are easy to install and resistant to many chemicals. Despite their reduced load-bearing capacity, advancements in materials technology are enhancing their strength and usability, making them a viable option in specific applications where environmental exposure is a concern. Architectural Gratings Merging Functionality with Aesthetics Architectural gratings emphasize aesthetic appeal alongside functionality, offering options that blend seamlessly into modern designs. These gratings are often made from stainless steel or perforated metal and are used in facades, sunshades, and flooring that demand visual elegance. They help create striking visual effects while providing essential functions such as light diffusion and temperature control in buildings. High customizability allows architects to experiment with texture, pattern, and material, fueling innovation in sustainable and functional design. Trust and Expertise in Grating Selection Selecting the appropriate type of grating involves an intricate balance of factors including load requirements, environmental conditions, aesthetic goals, and budget considerations. Consulting with grating specialists can provide tailored advice based on decades of industry experience. Informed by real-world usage and expert knowledge, these professionals offer insights that go beyond standard specifications, enhancing the effectiveness and lifespan of the installation. In summary, understanding the different types of gratings and their specific applications empowers stakeholders to make decisions with confidence, ensuring safety, functionality, and design appeal. Whether prioritizing durability, weight, corrosion resistance, or aesthetics, the vast range of options available today guarantees a grating solution for every unique requirement.

Plastic Gratings Cost-Effective and Corrosion-Resistant Plastic gratings stand out due to their affordability and corrosion-resistant properties. Used mainly in decorative applications, light-duty pedestrian areas, and corrosive environments, they are easy to install and resistant to many chemicals. Despite their reduced load-bearing capacity, advancements in materials technology are enhancing their strength and usability, making them a viable option in specific applications where environmental exposure is a concern. Architectural Gratings Merging Functionality with Aesthetics Architectural gratings emphasize aesthetic appeal alongside functionality, offering options that blend seamlessly into modern designs. These gratings are often made from stainless steel or perforated metal and are used in facades, sunshades, and flooring that demand visual elegance. They help create striking visual effects while providing essential functions such as light diffusion and temperature control in buildings. High customizability allows architects to experiment with texture, pattern, and material, fueling innovation in sustainable and functional design. Trust and Expertise in Grating Selection Selecting the appropriate type of grating involves an intricate balance of factors including load requirements, environmental conditions, aesthetic goals, and budget considerations. Consulting with grating specialists can provide tailored advice based on decades of industry experience. Informed by real-world usage and expert knowledge, these professionals offer insights that go beyond standard specifications, enhancing the effectiveness and lifespan of the installation. In summary, understanding the different types of gratings and their specific applications empowers stakeholders to make decisions with confidence, ensuring safety, functionality, and design appeal. Whether prioritizing durability, weight, corrosion resistance, or aesthetics, the vast range of options available today guarantees a grating solution for every unique requirement.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025