- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Јан . 20, 2025 00:15

Back to list

galvanized grating cost

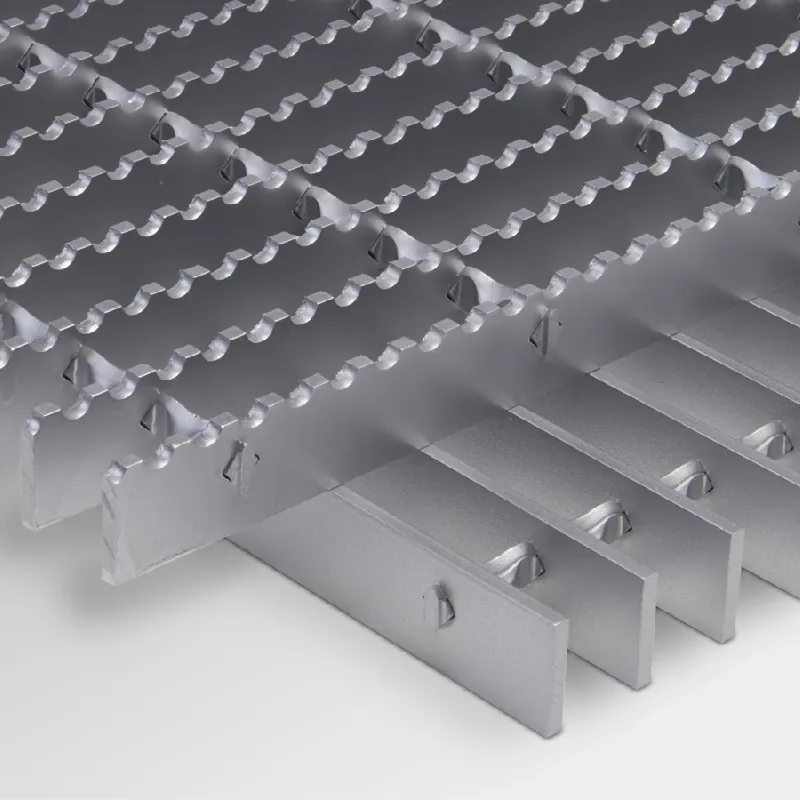

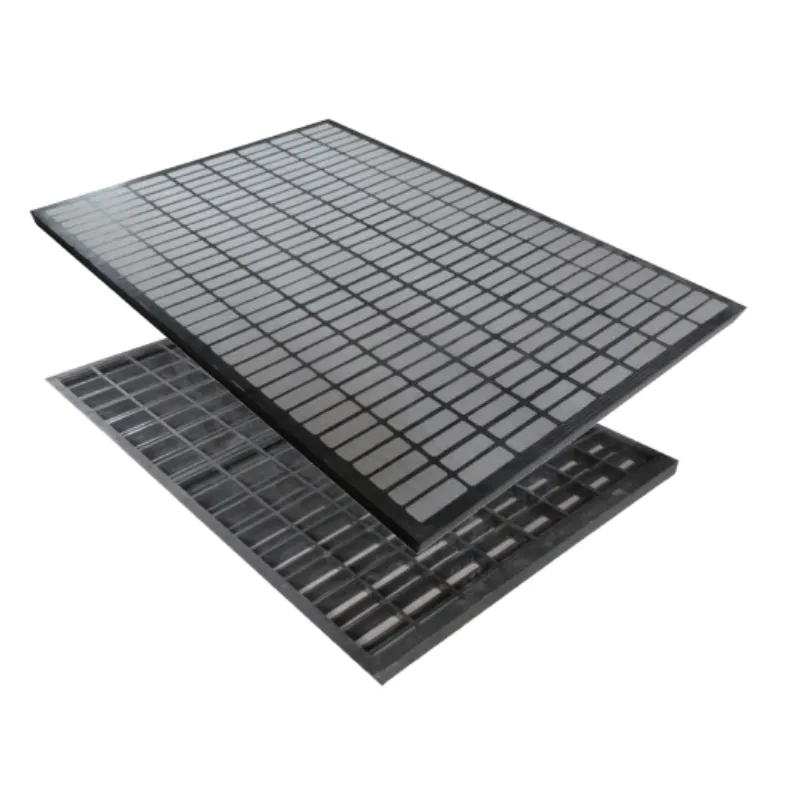

Galvanized grating has become a cornerstone in a myriad of industrial applications, revered for its durability, safety, and anti-corrosive properties. Industries ranging from manufacturing to public works rely on this product to enhance safety and cost efficiency. However, as demand increases, so do questions regarding the cost-effectiveness and total expenditure associated with galvanized grating. Understanding the financial implications and investment value is crucial for industry professionals and businesses aiming to make informed purchasing decisions.

For industry experts looking to optimize the procurement process, it is crucial to consider customization options. Custom-sized gratings can be tailored to fit specific structural needs, and while they may carry a higher upfront cost, the precise fit can lead to enhanced efficiency and safety. Moreover, consulting with seasoned suppliers experienced in galvanized grating can provide valuable insights into the most cost-effective solutions without compromising on quality or performance. Trust is another cornerstone when dealing with galvanized grating costs. Ensuring the credibility of suppliers through certifications and verified reviews solidifies trust in product quality and service reliability, reducing the risks of unexpectedly high lifecycle costs. Professionals with expertise in supply chain management can offer guidance and verification, enhancing decision-making processes for businesses entering or expanding within the market. Industry associations and trade publications also serve as reputable sources for the latest product innovations, pricing benchmarks, and market trends, further improving the knowledge base surrounding galvanized grating costs. To put into practice these strategic insights on galvanized grating costs requires a blend of experience, expertise, authoritativeness, and trustworthiness. The ultimate goal is not merely to focus on upfront costs but to embrace a comprehensive perspective on total value. This strategic approach supports businesses in leveraging galvanized grating as a sustainable, efficient, and economically sound solution for their infrastructure needs.

For industry experts looking to optimize the procurement process, it is crucial to consider customization options. Custom-sized gratings can be tailored to fit specific structural needs, and while they may carry a higher upfront cost, the precise fit can lead to enhanced efficiency and safety. Moreover, consulting with seasoned suppliers experienced in galvanized grating can provide valuable insights into the most cost-effective solutions without compromising on quality or performance. Trust is another cornerstone when dealing with galvanized grating costs. Ensuring the credibility of suppliers through certifications and verified reviews solidifies trust in product quality and service reliability, reducing the risks of unexpectedly high lifecycle costs. Professionals with expertise in supply chain management can offer guidance and verification, enhancing decision-making processes for businesses entering or expanding within the market. Industry associations and trade publications also serve as reputable sources for the latest product innovations, pricing benchmarks, and market trends, further improving the knowledge base surrounding galvanized grating costs. To put into practice these strategic insights on galvanized grating costs requires a blend of experience, expertise, authoritativeness, and trustworthiness. The ultimate goal is not merely to focus on upfront costs but to embrace a comprehensive perspective on total value. This strategic approach supports businesses in leveraging galvanized grating as a sustainable, efficient, and economically sound solution for their infrastructure needs.

Share

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025