- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Cost Analysis of Galvanized Grating for Various Applications and Projects

Understanding the Cost of Galvanized Grating An In-depth Analysis

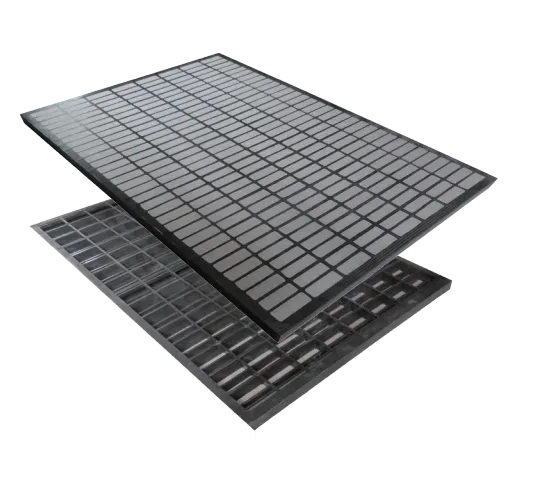

Galvanized grating is a popular choice in various industrial and commercial applications due to its durability, corrosion resistance, and cost-effectiveness. Whether used in walkways, platforms, or drainage systems, galvanized grating provides a sturdy solution that can withstand heavy loads and harsh environmental conditions. However, when considering the adoption of galvanized grating, it is essential to understand the cost implications involved.

What is Galvanized Grating?

Galvanized grating is typically made from steel with a hot-dip galvanization process applied to it. This process involves dipping the steel grating in molten zinc, which forms a protective layer against rust and corrosion. The result is a product that not only has a long lifespan but also requires minimal maintenance, making it an appealing option for many projects.

Factors Influencing the Cost

1. Material Type The primary factor influencing the cost of galvanized grating is the type of material used. While mild steel is commonly used due to its cost-effectiveness, stainless steel grating may be necessary for environments that are highly corrosive. Stainless steel tends to be more expensive, impacting overall project costs.

2. Grating Type and Design Different types of grating are available, each designed for specific applications. For instance, welded grating, which consists of metal bars welded together, is often more robust and priced higher than riveted or swaged options. Custom designs can further increase the cost, depending on the complexity of the structure and the specific requirements of the project.

galvanized grating cost

3. Size and Dimensions The size of the grating plays a significant role in determining the cost. Larger panels typically cost more due to the increased material and fabrication requirements. Additionally, thickness and load-bearing capacity can also affect pricing.

4. Installation Costs While the cost of the grating itself is an important consideration, installation costs must be factored in as well. Depending on the complexity of the installation process and the labor costs in a particular region, this can add a significant amount to the overall project budget.

5. Market Demand Like many materials, the cost of galvanized grating can fluctuate based on market demand and supply conditions. In times of high demand, prices may rise, while a surplus of materials could lead to cost reductions.

Cost Comparison

When comparing galvanized grating to other materials, such as aluminum or fiberglass grating, it’s important to consider not just the initial cost but the total cost of ownership over time. While aluminum might be lighter and resistant to corrosion, it is often more expensive. Fiberglass, while non-corrosive, may not support heavy loads as effectively as galvanized steel and could also be pricier.

Conclusion

The cost of galvanized grating is influenced by several factors, including material type, design, size, installation requirements, and market conditions. By understanding these variables, businesses can make informed decisions that align with their budgetary constraints and project needs. Ultimately, the initial investment in galvanized grating may be offset by its long-term durability and low maintenance costs, making it a worthy consideration for various applications. When planning your next project, take the time to evaluate all aspects of cost and performance to ensure you choose the best solution for your specific requirements.

-

Welded Steel Bar Grating: The Strongest Choice for Industrial FlooringNewsMay.21,2025

-

Steel Grating for Sale: The Ultimate Anti-Slip SolutionNewsMay.21,2025

-

Steel Frame Shaker Screens: Unmatched Durability for Demanding OperationsNewsMay.21,2025

-

Shaker Screens: Your Ultimate Solution for Oil & Gas FiltrationNewsMay.21,2025

-

Press Locked Steel Grating: The Smarter Choice for Heavy-Duty FlooringNewsMay.21,2025

-

Helicopter Deck Safety Nets: Protect Your Crew and EquipmentNewsMay.21,2025