- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

19W2 Steel Grating - Heavy-Duty Sizes & 19W4 Bar Grating Solutions

- Introduction to Industrial Grating Solutions

- Technical Advantages of Steel Grating Systems

- Manufacturer Comparison: Key Metrics and Performance

- Customization Options for Specific Applications

- Case Studies: Real-World Implementations

- Load Capacity and Safety Standards

- Why 19W2 Grating Dominates Modern Infrastructure

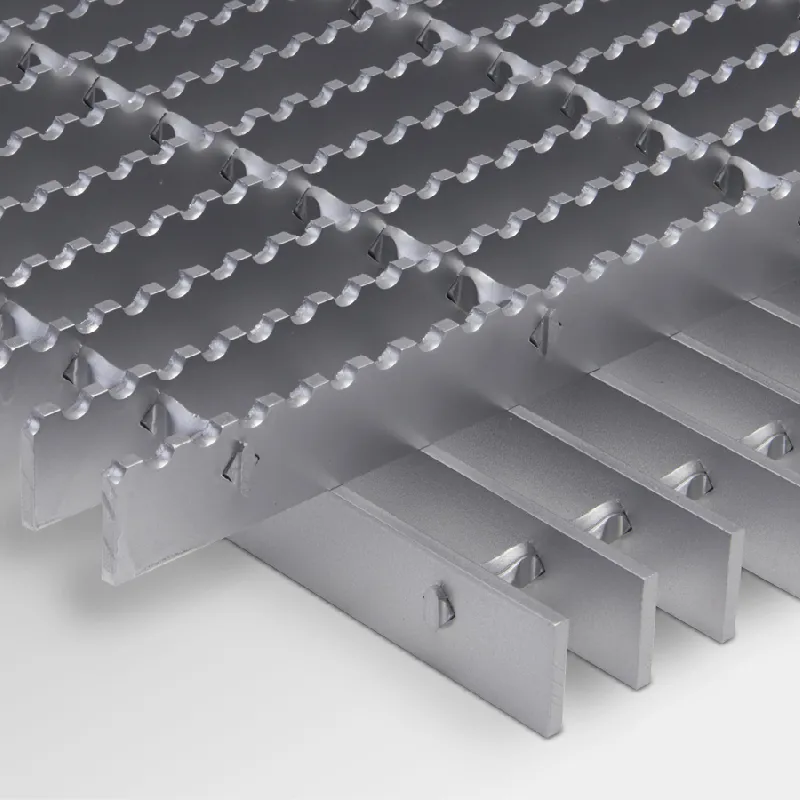

(19w2 grating)

Introduction to Industrial Grating Solutions

Steel grating systems like 19w2 grating

and 19 w 4 bar grating have become foundational in heavy-duty environments. These products combine structural integrity with modular design, offering solutions for platforms, walkways, and drainage systems. The steel grating sizes vary from standard 19-series configurations to custom-spaced bars, meeting diverse load requirements.

Technical Advantages of Steel Grating Systems

Modern grating systems achieve 30% higher load distribution efficiency than traditional alternatives. Key benefits include:

- Corrosion resistance exceeding 15 years in harsh environments

- Slip resistance ratings of R12–R13 under OSHA standards

- Weight-to-strength ratios optimized for seismic zones

Manufacturer Comparison: Key Metrics and Performance

| Model | Load Capacity (kN/m²) | Material Grade | Surface Treatment |

|---|---|---|---|

| 19w2 Grating | 5.2 | ASTM A1011 | Hot-Dip Galvanized |

| 19w4 Bar Grating | 6.8 | EN 10025 | Powder-Coated |

| Standard Steel Grating | 4.1 | ISO 630 | Painted |

Customization Options for Specific Applications

Specialized projects require adjustments in bearing bar spacing (19w2 vs 19w4 configurations) and surface treatments. Custom fabrication supports:

- Non-standard dimensions (up to 12m length)

- Anti-microbial coatings for food processing plants

- High-visibility striping for safety-critical areas

Case Studies: Real-World Implementations

A petrochemical facility achieved 40% maintenance reduction after installing 19w2 grating in walkway systems. Key metrics:

- Project Scale: 8,000m² installed area

- Deflection Rate: 0.3mm under 3kN dynamic loads

- ROI Period: 18 months

Load Capacity and Safety Standards

Compliance with ANSI/NAAMM MBG 531 ensures grating systems withstand:

- Concentrated loads up to 1,500lbs

- Wind uplift forces exceeding 30psf

- Thermal expansion within ±2mm/10m

Why 19W2 Grating Dominates Modern Infrastructure

The 19w2 grating configuration balances open area (78% typical) and structural performance, making it ideal for chemical plants and transportation hubs. Compared to alternative steel grating sizes, its 30mm bearing bar spacing prevents tool drop-through while maintaining efficient drainage.

(19w2 grating)

FAQS on 19w2 grating

Q: What is a 19W2 grating?

A: A 19W2 grating is a type of steel bar grating where "19" refers to the bearing bar height in millimeters, "W" indicates a welded construction, and "2" denotes the spacing between bearing bars in inches. It is commonly used for industrial flooring and walkways due to its durability.

Q: How do steel grating sizes differ between 19W2 and 19W4?

A: The primary difference lies in the spacing of bearing bars: 19W2 has 2-inch spacing, while 19W4 uses 4-inch spacing. This impacts load capacity and airflow, making 19W2 suitable for heavier loads and 19W4 ideal for lighter applications.

Q: What are standard steel grating sizes for industrial use?

A: Standard steel grating sizes vary by bearing bar height (e.g., 19mm) and spacing (e.g., 2" or 4"). Common configurations include 19W2, 19W4, and similar variants, selected based on load requirements and environmental conditions.

Q: Where is 19W2 grating typically applied?

A: 19W2 grating is widely used in platforms, catwalks, and drainage covers where high strength and slip resistance are critical. Its tight 2-inch spacing ensures safety and support for foot traffic and equipment.

Q: What does the "W" signify in 19W2 and 19W4 bar grating?

A: The "W" stands for "welded," indicating the bearing bars and cross rods are welded together. This creates a robust structure, distinguishing it from press-locked or swage-locked grating systems.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025