- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

grating stainless

Understanding Grating Stainless Steel Benefits and Applications

Grating stainless steel has become an essential material in various industries due to its unique properties and versatile applications. This article will explore what grating stainless steel is, its advantages, and where it is commonly used.

What is Grating Stainless Steel?

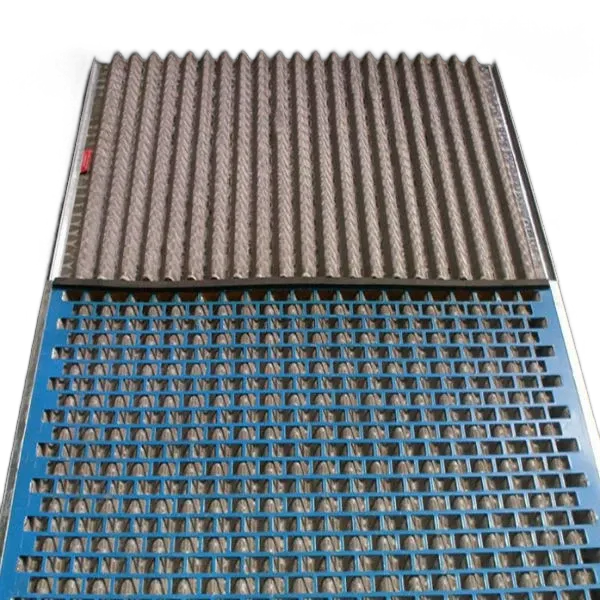

Grating stainless steel refers to a type of steel framework typically used as a flooring or walkable surface, built from stainless steel bars that are arranged in a grid pattern. The spaces in between the bars allow for drainage and airflow, making this material ideal for applications where liquids may be present or where a clean environment is critical.

The core material, stainless steel, is an alloy known for its excellent corrosion resistance, durability, and aesthetic appeal. It typically contains a minimum of 10.5% chromium, which forms a passive layer of chromium oxide on the surface, protecting it from rust and staining. This property is especially valuable in environments exposed to harsh conditions, such as chemicals, saltwater, or high humidity.

Advantages of Grating Stainless Steel

1. Corrosion Resistance One of the most significant advantages of grating stainless steel is its resistance to corrosion and rust. Unlike carbon steel, stainless steel does not easily oxidize, making it suitable for industries that deal with corrosive substances or operate in wet or humid environments.

2. Durability and Strength Stainless steel grating is incredibly strong and can withstand heavy loads and impacts. It provides a robust surface that handles foot traffic, vehicular movement, and various forms of mechanical stress, ensuring longevity and safety in industrial settings.

3. Low Maintenance Requirements The non-porous nature of stainless steel makes it easy to clean and maintain. Unlike materials that may require regular sealing or treatment to prevent degradation, stainless steel grating can simply be hosed down or wiped clean, reducing labor costs and time.

4. Versatility Grating stainless steel can be used in a myriad of applications, from walkways and platforms to drainage systems and industrial flooring. Its adaptability makes it a preferred choice across multiple industries, including food processing, pharmaceuticals, petrochemicals, and wastewater management.

5. Aesthetic Appeal Stainless steel grating adds a modern, sleek look to areas where it is installed. Its reflective surface can enhance the overall appearance of facilities, making it a popular choice for architectural applications.

grating stainless

6. Safe and Slip-Resistant Many varieties of stainless steel grating come with added surface textures or patterns that enhance traction, reducing the risk of slips and falls. This quality is crucial in environments where safety is a priority, such as in factories and warehouses.

Applications of Grating Stainless Steel

Grating stainless steel finds applications across diverse sectors due to its favorable characteristics. Some notable uses include

- Industrial Flooring In manufacturing plants, stainless steel grating is often used for elevated walkways, work platforms, and machinery access points due to its capacity to bear heavy loads and resist corrosion.

- Wastewater Treatment In treatment facilities, stainless steel grating is employed in various structures, including walkways over tanks and as support for screening systems, where exposure to water and chemicals occurs.

- Food and Beverage Industry The hygienic properties of stainless steel make it an ideal choice for processing plants, where cleanliness is critical. Grating is used in areas that contact food and other consumables, ensuring compliance with health regulations.

- Marine Applications Given its corrosion-resistant nature, stainless steel grating is often utilized in shipbuilding, docks, and other maritime applications where it is exposed to saltwater and harsh weather conditions.

- Architectural Elements Beyond functional uses, stainless steel grating is also used in modern architectural designs for facades, railings, and decorative elements due to its aesthetic versatility and durability.

Conclusion

Grating stainless steel is a superior choice for various applications, ranging from industrial flooring to architectural features. Its unique combination of strength, corrosion resistance, low maintenance, and aesthetic appeal makes it an invaluable material in today’s manufacturing, construction, and design realms. Choosing stainless steel grating ensures safety, longevity, and functionality, aligning perfectly with modern demands for durability and efficiency.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025