- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

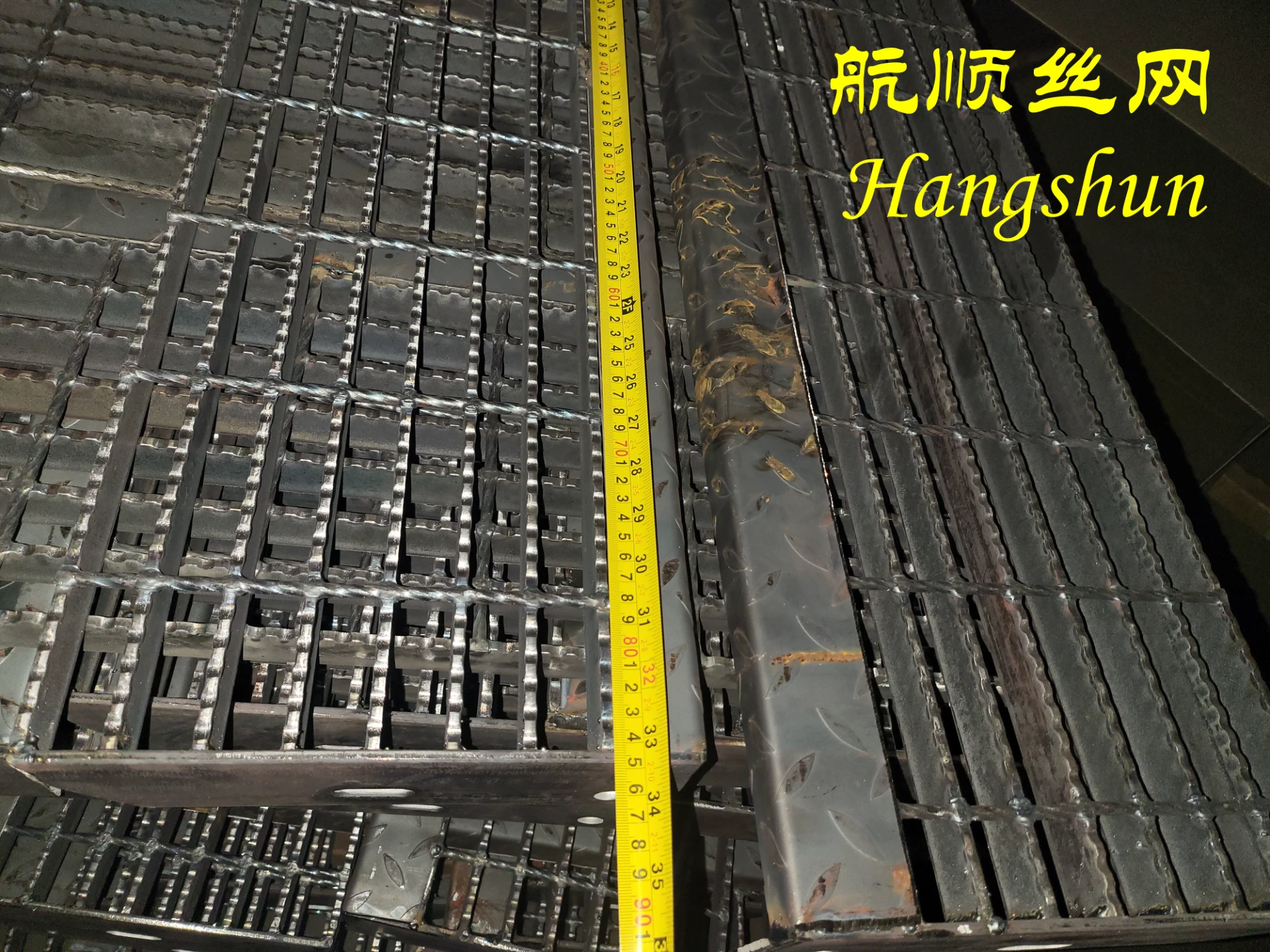

derrick shaker screens

The Importance of Derrick Shaker Screens in the Drilling Industry

In the field of drilling and exploration, efficiency and precision are critical. One of the key components that contribute to the effectiveness of drilling operations is the Derrick shaker screen. This innovative technology plays an essential role in the separation of drilling fluids and solid particles, ensuring a cleaner, safer, and more productive drilling process.

Derrick shaker screens are designed for use with shale shakers, which are devices that filter drilling fluid from the cuttings produced during the drilling process. These screens are vital for maintaining the quality and integrity of the drilling fluid, which serves multiple purposes it cools the drill bit, carries the cuttings to the surface, and supports the formation of boreholes.

The design of Derrick shaker screens is noteworthy. Constructed with advanced materials, these screens exhibit high tensile strength and durability. The screens are typically made from steel or composite materials, ensuring that they can withstand the extreme conditions of drilling operations, including high pressures and abrasive materials. Derrick Industries has refined the engineering of shaker screens, resulting in products that not only enhance performance but also extend the lifespan of the equipment.

One of the most significant advantages of Derrick shaker screens is their efficiency in the separation process. By utilizing a combination of different mesh sizes, the screens can effectively separate various solid particle sizes from the drilling fluid. Larger particles can be filtered out, allowing smaller particles to remain in suspension, which is critical for optimizing the fluid's properties. This selective separation helps to improve the overall drilling performance, reduces downtime associated with equipment maintenance, and lowers operational costs.

derrick shaker screens

Additionally, Derrick shaker screens come in various configurations to meet the specific needs of different drilling operations. They can be customized based on the type of drilling fluid, the nature of the formation being penetrated, and the desired rate of cuttings removal. This level of customization ensures that operators can optimize their drilling parameters, leading to higher efficiency and productivity.

The integration of advanced technology into the design of Derrick shaker screens has also led to improvements in monitoring and control. Many modern shaker screens are equipped with sensors and monitoring systems that allow operators to track performance in real time. These systems can provide valuable data on fluid characteristics and screen performance, enabling quick adjustments to be made as conditions change. This data-driven approach not only enhances operational efficiency but also contributes to more informed decision-making processes.

Furthermore, the environmental impact of drilling operations is a growing concern across the industry. Derrick shaker screens help to mitigate this issue by efficiently managing drilling waste. By maximizing the recovery of drilling fluids and properly managing cuttings, operators can reduce the volume of waste generated during drilling, leading to a more sustainable operation. This is increasingly important as regulatory frameworks tighten and the pressure to adopt eco-friendly practices increases.

In conclusion, Derrick shaker screens are a critical component in the drilling industry, serving as a key technology for separating drilling fluids from solids. Their advanced design, efficiency, and adaptability make them invaluable for optimizing drilling operations and reducing costs. As the industry continues to evolve, the role of these shaker screens will undoubtedly grow, contributing to more sustainable practices and improved outcomes for drilling projects. For operators looking to enhance their drilling efficiency and management of resources, investing in high-quality Derrick shaker screens is a step in the right direction.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025