- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

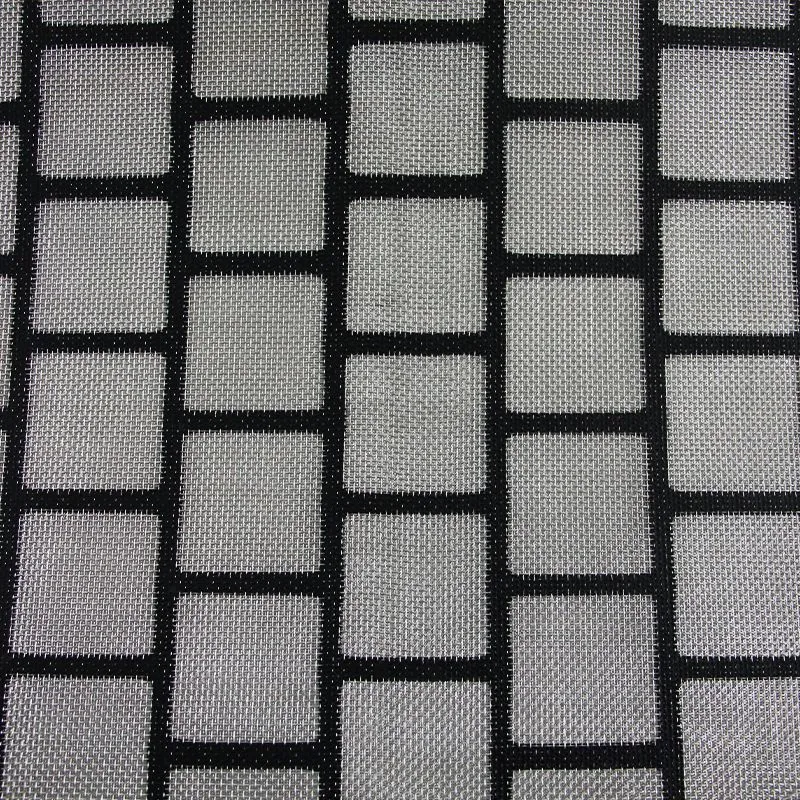

concrete weight coating mesh

Understanding Concrete Weight Coating Mesh An Essential Component in Pipeline Protection

Concrete weight coating mesh is a crucial component used in the construction and installation of underwater pipelines. This specialized mesh is designed to provide reinforcement and support to concrete coatings, ensuring that pipelines remain stable and well-protected in harsh aquatic environments. As the demand for efficient and durable pipeline systems increases, the significance of concrete weight coating mesh becomes increasingly evident.

The primary function of concrete weight coating is to provide ballast for submerged pipelines, ensuring they remain submerged and preventing flotation. In various applications, such as oil and gas transportation, the integrity of these pipelines is vital. They must withstand external pressures, resist environmental degradation, and remain in place over time. This is where concrete weight coating mesh comes into play, as it enhances the structural performance of the concrete coating.

Typically made from high-strength steel wire, the mesh offers several advantages. Firstly, it provides tensile strength, allowing the coated concrete to withstand the forces exerted by water currents, soil pressure, and other environmental factors. Moreover, the mesh promotes better adhesion between the concrete and the underlying pipeline, reducing the risk of delamination and increasing the overall durability of the coating system.

concrete weight coating mesh

The manufacturing process of concrete weight coating mesh involves precise engineering to ensure that the mesh has the right characteristics for its intended application. The wire is fabricated into a grid pattern, which is then coated with protective layers to prevent corrosion. This anti-corrosive feature is vital, as underwater environments can be particularly harsh, with exposure to various chemicals and substances that can degrade materials over time.

When it comes to installation, the concrete is poured over the mesh to form a robust shielding layer. This process not only adds weight to the pipeline but also significantly enhances its resilience. The combination of concrete and mesh creates a composite structure that effectively absorbs impact and resists punctures, making it an ideal choice for pipelines laid on the ocean floor or in other challenging terrains.

In conclusion, concrete weight coating mesh serves as an indispensable element in the construction and maintenance of underwater pipelines. By providing strength and stability to concrete coatings, it plays a pivotal role in protecting vital infrastructure. As industries continue to evolve and seek more efficient solutions for underwater installations, the importance of concrete weight coating mesh will undoubtedly grow, ensuring the safe and consistent transportation of resources essential to modern society. Its durability, strength, and resistance to environmental challenges underscore its importance in the field of pipeline engineering.

-

Upgrade Your Industrial Operations with Durable Steel GratingNewsJul.21,2025

-

Transform Your Flooring Solutions with Quality Floor GratingNewsJul.21,2025

-

Top-Quality Shale Shaker Screens for Your Drilling NeedsNewsJul.21,2025

-

High-Quality Steel Grating for All Your Industrial NeedsNewsJul.21,2025

-

Explore the Durability and Versatility of Galvanized Steel GratingNewsJul.21,2025

-

Ensure Maximum Safety with Premium Safety NetsNewsJul.21,2025