- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

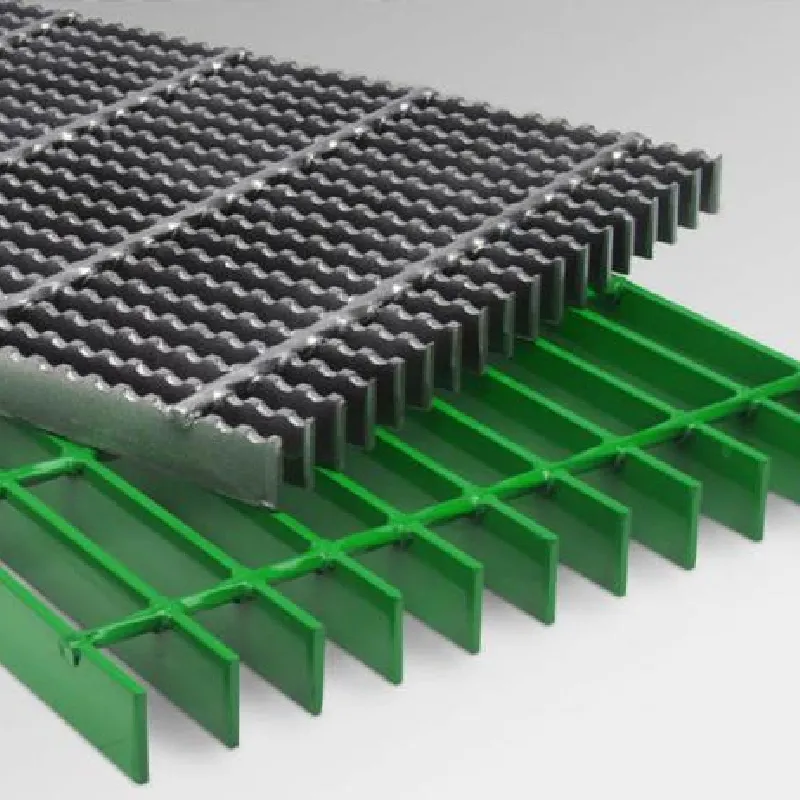

Carbon Steel Bar Grating Design for Enhanced Durability and Performance in Industrial Applications

Understanding Carbon Steel Bar Grating A Comprehensive Overview

Carbon steel bar grating is a widely utilized material in various industrial applications due to its remarkable strength, durability, and cost-effectiveness. This versatile product is formed by welding together a series of parallel bars, typically made from carbon steel, to create a lattice-like structure that allows for maximum airflow and drainage while providing excellent load-bearing capabilities.

Composition and Properties

Carbon steel is an alloy made primarily of iron, with carbon as the main alloying element. This combination imparts several beneficial properties to the material, making it suitable for heavy-duty applications. The carbon content can vary, often ranging from 0.05% to 2%, affecting the material's strength, ductility, and hardness. The higher the carbon content, the stronger the steel, but this can also reduce its ductility, making it more brittle.

Carbon steel bar grating typically consists of individual bars arranged in a grid pattern, with the load-bearing bars placed at regular intervals. This design not only optimizes the strength-to-weight ratio but also ensures that the structure is lightweight yet sturdy enough to support heavy loads. Furthermore, the open spaces between the bars reduce the build-up of debris, allowing for easy cleaning and maintenance.

Manufacturing Process

The manufacturing of carbon steel bar grating involves several key steps. It begins with the cutting of steel bars to specified lengths, followed by the arrangement of these bars into a grid layout. The bars are then welded at their intersections, creating a rigid structure that can withstand significant weight and stress.

One of the most important considerations during the manufacturing process is the quality of the welds, as they directly influence the structural integrity of the grating. Advanced techniques such as resistance welding and automatic welding machines are often employed to ensure consistency and strength in the final product.

Applications

Carbon steel bar grating is used in a diverse range of applications across various industries. Its exceptional strength makes it ideal for use in heavy industrial environments such as factories, power plants, and refineries, where it can support machinery, walkways, and platforms.

carbon steel bar grating

In construction, carbon steel bar grating is often employed as flooring in elevated walkways, providing a safe passage for workers while allowing for the drainage of water and debris

. This is particularly beneficial in outdoor settings where weather conditions could otherwise compromise safety.Additionally, this material is commonly used in municipal applications, such as drainage covers and grates, where its ability to withstand heavy traffic loads is essential. The open design allows for efficient water flow while providing a sturdy surface.

Advantages

There are numerous advantages associated with using carbon steel bar grating. Firstly, its high load-bearing capacity makes it suitable for demanding applications, where safety and reliability are paramount. Additionally, the open design minimizes debris accumulation, making it easy to clean and maintain.

Cost-effectiveness is another significant benefit. Carbon steel is generally less expensive than other materials such as stainless steel or aluminum, making it a popular choice for budget-conscious projects without compromising performance. Moreover, the durability of carbon steel means that it can withstand harsh conditions over time, reducing the need for frequent replacements.

Disadvantages and Considerations

Despite its many advantages, carbon steel bar grating does have its drawbacks. One significant concern is its susceptibility to corrosion, especially in environments exposed to moisture or chemicals. To combat this, protective coatings such as galvanization, painting, or powder coating are often applied to enhance its resistance to rust and extend its lifespan.

Another consideration is the weight of carbon steel in comparison to lighter materials. While this is generally not an issue for structural applications, in scenarios where weight is a critical factor, alternatives may need to be considered.

Conclusion

In conclusion, carbon steel bar grating is a robust and versatile material ideal for various industrial and municipal applications. Its combination of strength, cost-effectiveness, and ease of maintenance make it an attractive choice for engineers and architects alike. By understanding its properties, manufacturing process, advantages, and potential downsides, businesses can make informed decisions about incorporating carbon steel bar grating into their projects, ensuring safety and efficiency in their operations.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025