- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

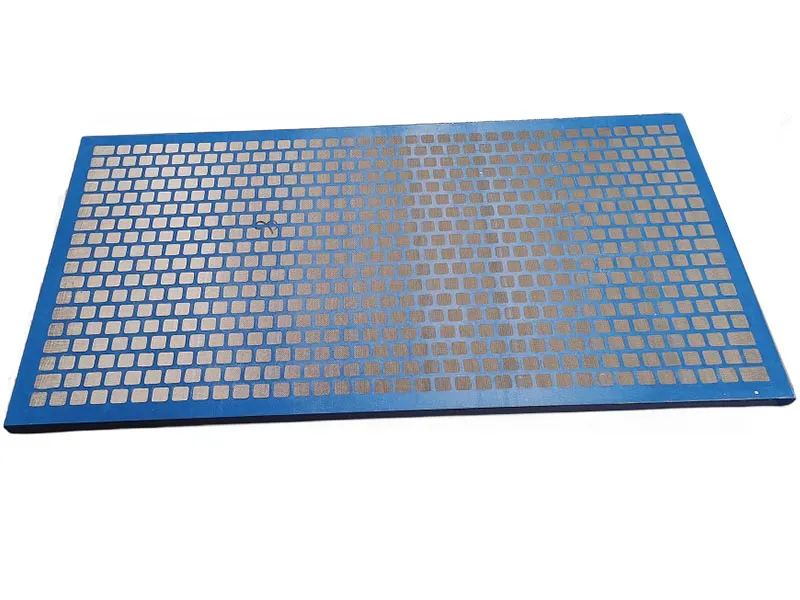

industrial shaker screen

Understanding Industrial Shaker Screens

In various industrial sectors, particularly in the oil and gas industry, the efficiency of separation processes can be significantly influenced by the type of screens used in shakers. Industrial shaker screens are essential components in equipment that separates solid materials from liquids, allowing for the effective management of waste materials and the recovery of valuable resources.

What are Industrial Shaker Screens?

Industrial shaker screens are used in vibrating screens and shale shakers to separate different types of materials based on their size. These screens work by utilizing vibration and gravity to induce the movement of materials across the screen surface, allowing smaller particles to pass through the screen while larger particles remain on top. The screens are typically made from steel mesh or polyurethane and come in various sizes, depending on the specific application.

Importance in Drilling Operations

In the oil and gas drilling sector, shaker screens play a critical role in the drilling fluid management process. Drilling fluids, also known as mud, are essential for lubricating the drill bit, stabilizing the borehole, and carrying cuttings back to the surface. Once the drilling process is underway, it generates a significant amount of cuttings, which must be separated from the drilling fluid. Here, shaker screens are invaluable as they allow for efficient separation, ensuring that the drilling fluid can be reused, thus reducing waste and operational costs.

Types of Shaker Screens

There are various types of shaker screens designed for specific applications. The most common types include

1. Composite Shaker Screens These screens combine a steel frame with a composite material, providing enhanced durability and resistance to wear. They are highly favored in industries for their longer lifespan and better performance.

2. Steel Frame Screens Traditional steel mesh screens that offer robust strength and are suitable for a wide range of applications but may not last as long as composite alternatives.

industrial shaker screen

3. Polyurethane Screens Made entirely of polyurethane, these screens are lightweight, resistant to chemicals, and offer excellent resistance to abrasion, making them ideal for applications where harsher materials are processed.

4. Custom-Made Screens Depending on the specific needs of a project, custom designs can be manufactured to meet unique requirements for size, mesh opening, and durability.

Selecting the Right Shaker Screen

When selecting a shaker screen, several factors must be considered. This includes the type of material being processed, the desired separation size, and the overall operating environment. For instance, if the operation involves highly abrasive materials, a more durable screen, such as a composite or polyurethane screen, may be necessary.

Additionally, understanding the mesh configuration is vital. Different mesh designs can influence the flow rate and the separation efficiency. A finer mesh can capture smaller particles but may slow down the overall processing rate, while a coarser mesh might increase throughput but allow some unwanted materials to pass through.

Maintenance and Longevity

Proper maintenance of shaker screens is crucial for ensuring longevity and efficient operation. Regular inspections, timely replacements of worn screens, and keeping the shaker equipment clean can significantly enhance performance. Operators should follow the manufacturer’s guidelines for maintenance to avoid costly downtime and ensure optimal performance.

Conclusion

Industrial shaker screens are a fundamental component in various sectors, particularly in drilling operations. Their role in separating valuable materials from waste not only enhances operational efficiency but also supports sustainable practices by minimizing waste. With different types available, selecting the appropriate shaker screen tailored to specific operational needs is essential for achieving the best results. As industries continue to evolve, innovative designs and materials will ensure that shaker screens remain a vital asset in material separation processes.

-

Welded Steel Bar Grating: The Strongest Choice for Industrial FlooringNewsMay.21,2025

-

Steel Grating for Sale: The Ultimate Anti-Slip SolutionNewsMay.21,2025

-

Steel Frame Shaker Screens: Unmatched Durability for Demanding OperationsNewsMay.21,2025

-

Shaker Screens: Your Ultimate Solution for Oil & Gas FiltrationNewsMay.21,2025

-

Press Locked Steel Grating: The Smarter Choice for Heavy-Duty FlooringNewsMay.21,2025

-

Helicopter Deck Safety Nets: Protect Your Crew and EquipmentNewsMay.21,2025