- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

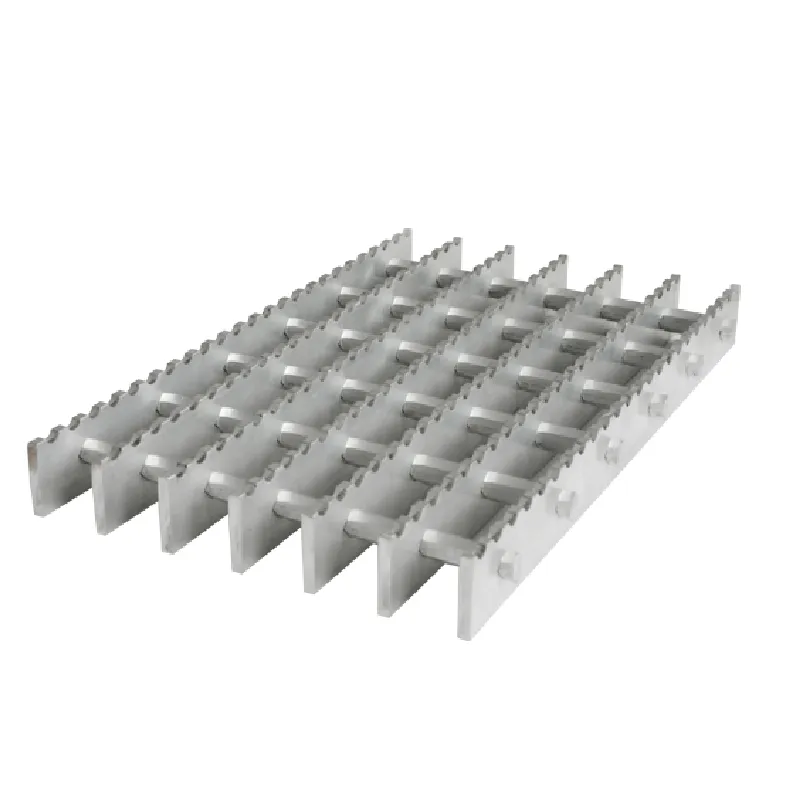

grating hot dip galvanized

Understanding Hot Dip Galvanized Grating A Comprehensive Overview

Hot dip galvanization is a well-known process utilized in various industries to improve the corrosion resistance of metal components. One of the remarkable applications of this technique is in the production of steel grating. This article delves into the characteristics, advantages, applications, and maintenance of hot dip galvanized grating, providing a complete understanding of its significance.

What is Hot Dip Galvanized Grating?

Hot dip galvanized grating is made by coating steel grating with molten zinc. This process involves submerging the steel grating in a vat of liquefied zinc at temperatures typically exceeding 450 degrees Celsius. The result is a durable, corrosion-resistant surface that can withstand harsh environmental conditions. Steel grating itself is composed of a series of parallel bars, which can be arranged in various patterns, used primarily for flooring, walkways, and platforms.

Advantages of Hot Dip Galvanized Grating

1. Corrosion Resistance The primary benefit of hot dip galvanization is its exceptional corrosion resistance. The zinc coating acts as a barrier, preventing moisture from coming into contact with the steel beneath. This makes hot dip galvanized grating ideal for use in outdoor environments or areas exposed to chemicals, such as waste treatment plants and industrial sites.

2. Longevity Hot dip galvanized grating can last up to 50 years or more with minimal maintenance. The thickness of the zinc layer and the conditions in which the grating is used significantly impact its lifespan, but overall, it provides a long-term solution for many applications.

3. Cost-effectiveness Although the initial manufacturing cost of hot dip galvanized grating may be higher than non-coated alternatives, its reduced need for maintenance and replacement in the long run makes it a more economical choice.

4. Strength and Durability Steel grating is inherently strong and can support heavy loads, making it suitable for various industrial applications. The galvanized coating adds to this strength, ensuring that grating retains its integrity and functionality even under stress.

grating hot dip galvanized

5. Aesthetic Appeal Hot dip galvanized grating has a clean and modern finish, making it suitable for architectural applications where appearance matters. Its shiny surface can enhance the overall look of structures.

Applications of Hot Dip Galvanized Grating

The versatility of hot dip galvanized grating makes it a preferred choice in a wide range of applications

- Industrial Flooring Used in factories and warehouses for walkways, platforms, and safety barriers, providing a secure and slip-resistant surface. - Drain Covers Used in drainage systems, ensuring that debris is kept out while allowing water to flow freely. - Platforms and Staircases Ideal for elevated structures, providing strength and safety. - Walkways in Outdoor Facilities Parks, zoo pathways, and other outdoor settings can benefit from the corrosion-resistant properties of galvanized grating. - Wastewater Treatment Plants Essential in environments prone to moisture and corrosive substances due to their durability.

Maintenance of Hot Dip Galvanized Grating

While hot dip galvanized grating requires minimal maintenance, periodic inspections should be conducted to identify any signs of wear or damage. Here are a few maintenance tips

- Regular Inspections Check for any signs of corrosion or structural damage, especially in areas where water accumulation may occur. - Cleaning Remove debris and contaminants that could hold moisture against the surface. A gentle wash with water and a brush can help maintain its appearance. - Repair If any damage is found, address it promptly. Small scratches can be touched up with zinc-rich paint to restore protection.

Conclusion

Hot dip galvanized grating is a robust and efficient solution for applications requiring durability and resistance to corrosion. Its combination of strength, longevity, cost-effectiveness, and aesthetic appeal makes it an excellent choice for various industries. Understanding its advantages and proper maintenance ensures that this valuable resource continues to serve its purpose effectively for years to come. Whether used in industrial settings or architectural designs, hot dip galvanized grating proves to be an asset, adapting to the demands of modern construction and design.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025